Introduction: Paper Bags Are Popular, and Your Business Needs Them

The world is becoming green. Paper bags are also being promoted by rules against plastic. Thus, paper bags are rapidly gaining popularity as the most popular environmentally friendly packaging. You can find paper bags everywhere: in malls, fast-food restaurants, fashion stores, and general stores. This change implies that individuals are more concerned about the environment. It also provides companies with a large opportunity to be socially responsible and enhance their brand image. To take advantage of this market trend, one of the first steps to a good future is to acquire an efficient, reliable paper bag making machine.

What a Paper Bag Making Machine Does and How It Works

Paper bag making machine is an automatic or semi-automatic industrial machine. It uses rolls or sheets of paper and converts them to various sizes and shapes of paper bags. This is how it usually goes:

- Paper Feeding: A paper roll goes into the machine.

- Folding: The paper is folded precisely into the main shape of the bag. This is dependent on the design of the bag.

- Gluing: The parts of the bag that are to be stuck together are covered with glue.

- Gluing: Glue is put on the parts of the bag that will stick together.

- Forming: Rollers and other tools press the paper. This makes it into a bag.

- Cutting and Collecting: The completed paper bags are divided. The machine then stacks or collects them.

Computer controls (PLCs) are common on newer paper bag machines. This implies that they work on most of the tasks. They regulate every step. This ensures that the bags are of good quality and the production is quick.

Paper Bag Machine Types and What They Make

Knowing about different paper bag machine types and their uses is important. This helps you make a good choice when buying one. Each machine is made for certain market needs and product types.

1. Flat Bottom Paper Bag Making Machine

- Features: This machine makes paper bags with a flat bottom. These bags usually do not have handles, or they have flat handles. They are simple but very useful. They are often made from one sheet of paper or a paper roll. Gluing is simple.

- Main Products:

- Bread Bags/Bakery Bags: These are light and let air through. They are good for bread, baguettes, cookies, and other baked goods. Bakeries and coffee shops use them.

- Pharmacy Bags: Drugstores use these bags for medicine. They are easy to use and keep things private.

- Envelope Bags/File Bags: These bags hold documents, tickets, or small items. Offices, banks, and mail services use them a lot.

- Small Retail Bags: For small items like candy, snacks, or jewelry. You find them in small shops and convenience stores.

- Supermarket Bulk Item Bags: Customers use these bags to get loose items like grains, nuts, or candy. They fit with eco-friendly trends.

- Industries and Uses: Bakeries, pharmacies, small supermarkets, general stores, inner packaging for deliveries, managing files. These machines are popular with small and medium businesses. Big companies also use them as extra equipment. This is because they are simple and cheap to keep.

2. Square Bottom Paper Bag Making Machine / SOS Bag Making Machine

- Features: This machine makes paper bags with a square bottom. The bag stands up when it has items inside. This makes it more stable and able to hold more weight. These machines usually have more complex ways to fold and glue the bottom. Some models can also add handles.

- Main Products:

- Shopping Bags: Used widely in stores, from daily shopping to brand shops. They are for clothes, shoes, makeup, and other goods. They are a big part of the shopping experience.

- Gift Bags: For gifts of all kinds. They often have nice printing and handles. This makes the gift seem more special.

- Food Delivery Bags/Fast Food Bags: Used by fast-food places, coffee shops, and delivery services for food like burgers, fries, and drinks. The strong bottom keeps things from spilling.

- Farm Product/Food Packaging Bags: For flour, rice, coffee beans, tea, and other farm goods. These bags need to be strong and let air through.

- Cement Bags/Chemical Bags: These are stronger square bottom bags. They hold heavy loose materials like building stuff and chemical powders. They must hold a lot of weight and keep out moisture.

- Industries and Uses: Big stores, fashion brands, restaurants, food processing, building material companies, chemical companies. Square bottom paper bags look good and are useful. They are the most wanted and used type of paper bag right now.

3. V-Bottom Paper Bag Making Machine

- Features: This machine makes paper bags with a V-shaped (or pointed) bottom. It does not have a separate flat base. These bags are usually for small or light items. They are simple, fast to make, and cheap.

- Main Products:

- Candy Bags/Snack Bags: Used in movie theaters, fun parks, and snack shops for popcorn, candy, and nuts.

- Pill Bags: Some drugstores use these to give out a few pills.

- Seed Bags: For small amounts of seeds or dried fruit.

- Industries and Uses: Snack shops, movie theaters, small drugstores, farming (for seeds). These machines are good when you do not need the bag to hold a lot of weight or stand up. They are for quick, cheap packaging.

4. Paper Bag with Handle Making Machine

- Features: This machine makes the main part of the paper bag (usually a square bottom bag). It also automatically makes and attaches the handles. Handles can be different types, mostly twisted handles or flat handles.

- Main Products:

- High-End Shopping Bags/Brand Bags: Used by luxury brands, clothing stores, and jewelers. The handle makes it easy to carry and makes the brand look better.

- Gift Packaging Bags: For any gift. They are easy to carry and make giving gifts better.

- Exhibition/Event Promotional Bags: Businesses give these out at shows, meetings, or sales events for papers or samples. Handles make them easier to carry and promote.

- E-commerce Delivery Bags: Some online stores use custom paper bags with handles for delivery. This makes getting packages better for customers.

- Industries and Uses: Brand retail, fashion, advertising, gift businesses, packaging for expensive items. Paper bags with handles are valuable because they are easy to use, look good, and help promote brands.

5. Roll-fed Paper Bag Making Machine

- Features: This type of machine uses paper rolls as its material. It handles the whole process: paper roll feeding, printing (on some models), folding, bottom gluing, forming, cutting, and collecting. Compared to machines that use single sheets of paper, roll-fed machines are usually more automatic. They produce faster. They are good for making many bags without stopping.

- Main Products:

- It can make many types (flat bottom, square bottom, V-bottom) and sizes of paper bags, with or without handles. It is flexible because you can change its setup to make different bag types.

- Industries and Uses:

- Large Packaging Makers: They need to make a lot of bags. They need fast, steady production of different paper bags for other businesses.

- Big Stores/Supermarkets: If they need a lot of paper bags, making their own can save money and help with supply.

- Big Food Companies: They use many paper bags for things like grains, sugar, and coffee.

- Online Store Logistics Centers: They use many paper bags for packing and sending items.

Knowing these different paper bag machine types and their many uses will help you find your market better. It will also help you pick the best equipment for your business goals and production needs.

How to Pick the Best Paper Bag Making Machine for Your Business

Picking the right paper bag machine means looking at many things. This makes sure you get the most from your money.

- Your Production Needs:

- Output: How many paper bags do you want to make each day, month, or year? This tells you if you need a fully automatic, semi-automatic, or fast machine.

- Bag Type and Size: What shape (square bottom, flat bottom, V-bottom) and size paper bags will you mainly make? Do you need handles?

- Paper Material: What kind of paper (kraft paper, coated paper, white cardboard, etc.) and what weight paper will you use? Can the machine use it?

- Budget and Return on Investment:

- Upfront Cost: The money you spend at the start. This includes buying the machine, shipping, setting it up, and training.

- Running Costs: Money spent on electricity, workers, paper, glue, and upkeep.

- Return on Investment (ROI): Figure out if the machine’s better production and saved money will pay back the starting cost quickly.

- Machine Performance and Technology:

- Automation Level: Machines that do more work themselves save money on workers and make more bags faster.

- Stability and Durability: Look at how the machine is built. See what brands of parts it uses (like electrical parts). Check the maker’s experience.

- Production Speed and Accuracy: High speed means many bags. High accuracy means good quality bags and less waste.

- Easy to Use and Maintain: Is the machine easy to run and fix every day? Does the seller give good service and parts?

- Supplier’s Reputation and Service:

- Maker’s Experience: Choose a seller who has made machines for a long time and has a good name.

- Quality Rules: Learn about their quality systems (like ISO 9001) and product checks (like CE, RoHS).

- After-Sales Service: This includes help with setup, training, warranty time, how fast they fix problems, and giving parts.

Paper Bag Machine Price and How Much You Get Back

The cost of a paper bag machine varies. It is based on its type, the extent to which it is automatic, the brand, the number of bags it produces and additional features. Prices range between tens of thousands to hundreds of thousands of US dollars.

Factors That Alter the Price:

- How Automatic It Is: Fully automatic machines are usually more expensive than ones that need more human work.

- Extra Features: Does it print, plastic coat, hole punch, or handle attach?

- Speed and Output: The faster and more frequently machines produce bags, the more expensive they are.

- Brand and Technology: Recognized brands and machines with new technology tend to be expensive.

Return on Investment (ROI) Analysis:

Purchasing a paper bag machine is not an expenditure of money once. It is a money-making investment. To calculate ROI, consider:

- Money Saved: You can make your own paper bags which may be cheaper than purchasing them. Producing many bags will significantly reduce the price per bag.

- Better Production: Bags are produced automatically and are much faster. They require less labor.

- Control Over Quality: Making your own bags helps you keep quality good and steady.

- Taking Market Chances: You are able to respond to shifts in what people desire rapidly. You are able to accept custom orders. You are able to expand your business.

As an example, KETE machines are quick and stable. Moreover, they have good after sales service that enables businesses to make money quickly. It also makes them continue performing well over a long period. Although it may be expensive initially, making things faster, reducing the cost per bag and satisfying the market requirements normally translates to quick recouping of the money and good profits.

Top 5 KETE Paper Bag Machines to Help Your Business Grow

KETE Group has a team that has more than thirty years of machine making. They have factories that have been in operation since 1983 in China. KETE has more than 80 countries where it sells and it sells more than 2000 machines annually. KETE adheres to quality regulations of ISO 9001. Their machines are all CE approved and some are RoHS compliant. This implies that they produce high quality machines. These are five KETE paper bag machines that we recommend. Their strengths can indeed benefit your company.

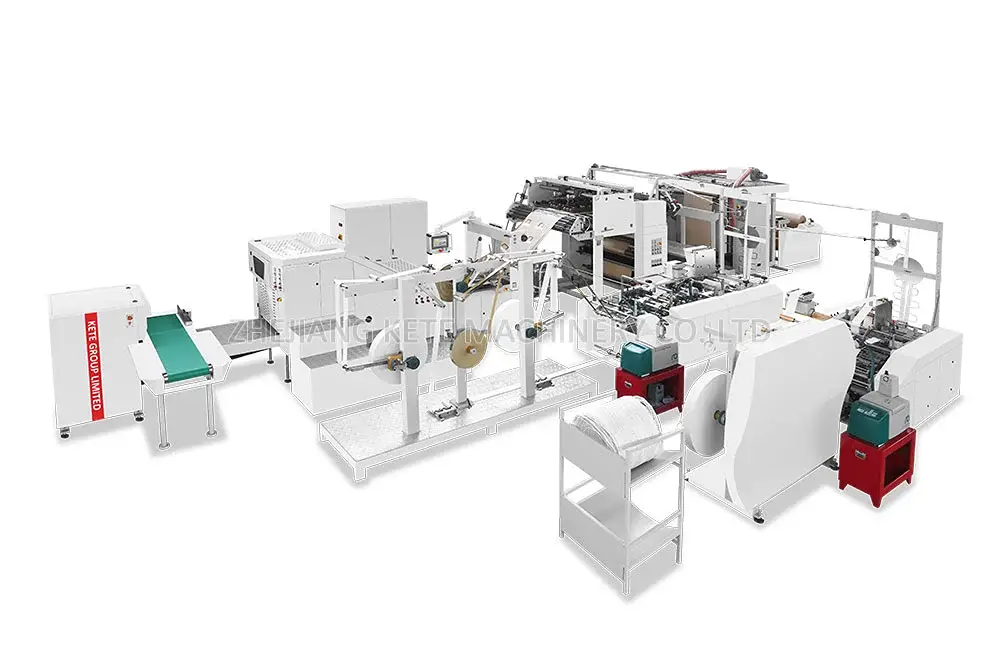

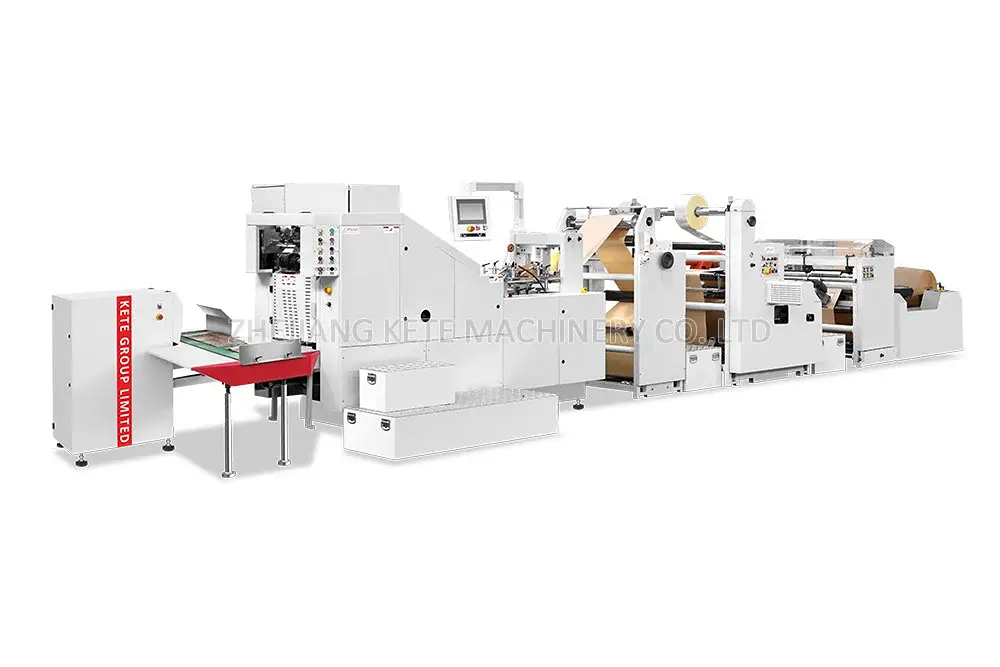

KTPM-BHB Fully Automatic Paper Bag Making Machine

Product Website: https://www.ketegroup.com/machine/paper-bag-making-machine/

- Key Advantages: This machine gives a complete handle bag solution. The KTPM-BHB makes bags and automatically adds twisted and flat handles. It makes up to 150 bags per minute. This makes production much simpler and saves money on machines and space. It fits many sizes. It supports bag widths from 200-550mm and bottom widths from 80-230mm. This means it can make many sizes of square bottom handle bags. It uses international brand electrical parts. It uses main parts from big brands like Schneider, Lenze, and SICK. This makes the machine very stable, precise, and strong.

- Reason to Recommend: If your business needs to make many high-quality square bottom paper bags with handles, like for retail brands, department stores, or gift packaging, the KTPM-BHB is a great choice. It will make your production much faster. It will cut your total costs. Its automatic process will make sure all bags are the same quality. This gives customers professional brand packaging.

| Parameter/Feature | Description |

| Finished Bag Type | Square bottom paper bags with twisted handles and flat handles |

| Bag Width | 200-550mm (7.87”-21.7”) |

| Bag Bottom Width | 80-230mm (3.15”-7.87”) |

| Paper Thickness | 80-150gsm |

| Max. Bag Making Speed | 150 pcs/min |

| Paper Roll Diameter | Φ1200mm (47.2”) |

| Main Parts | PLC Touch Screen: SCHNEIDER (France); PC Motion Controller/Servo Motor: LENZE (Germany); Inverter: DELTA (Taiwan); Photo Sensor: SICK (Germany); EPC: SELECTRA (Italy). You can add a 2-color/4-color in-line flexo printing machine. |

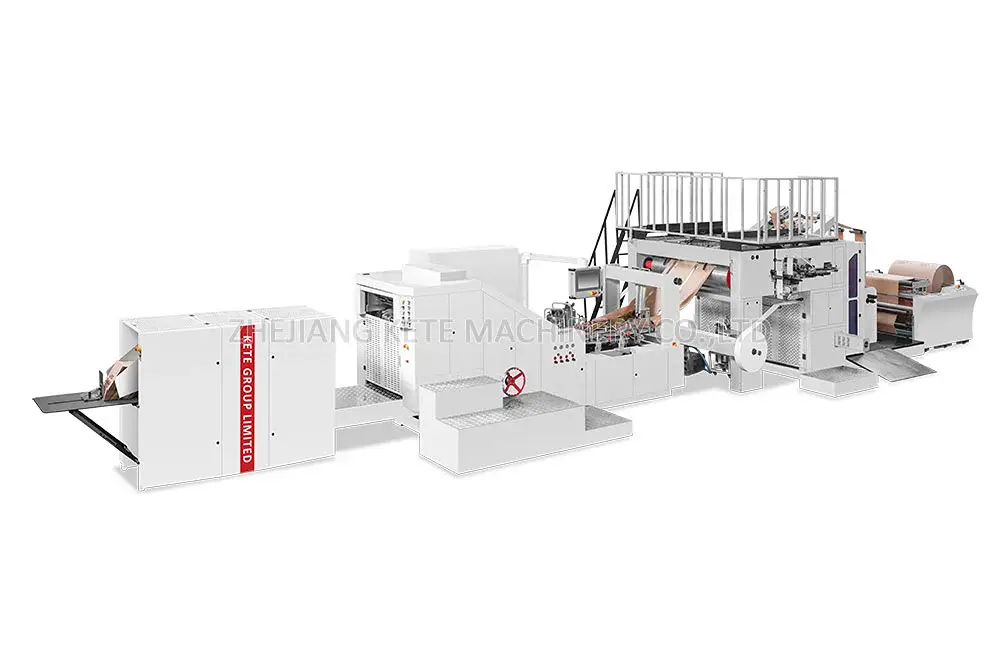

KTPM-BHFI Fully Automatic Paper Bag Manufacturing Machine

Product Website: https://www.ketegroup.com/machine/paper-bag-manufacturing-machine/

- Key Advantages: This machine has a special design for inner fold flat handles. The KTPM-BHFI makes square bottom bags with inner fold flat handles. It makes up to 150 bags per minute. This ensures handles are neat, strong, and save space. It has high accuracy and stability. It uses the same good electrical parts as the BHB. This makes sure the machine works precisely and reliably. It allows flexible size choices. It handles bag widths from 220-450mm and bottom widths from 80-220mm. This meets different market needs.

- Reason to Recommend: This machine is good for businesses that need to make many square bottom paper bags with inner fold flat handles. This is good for industries that need nice packaging and integrated handles, like fashion, gifts, or specialty retail. The KTPM-BHFI can help you quickly meet custom orders. It will also raise the value of your products and brand image.

| Parameter/Feature | Description |

| Finished Bag Type | Square bottom paper bags with inner fold flat handles |

| Bag Width | 220-450mm (8.66”-17.7”) |

| Bag Bottom Width | 80-220mm (3.15”-8.66”) |

| Paper Thickness | 80-150gsm |

| Max. Bag Making Speed | 150 pcs/min |

| Paper Roll Diameter | Φ1200mm (47.2”) |

| Main Parts | PLC Touch Screen: SCHNEIDER (France); PC Motion Controller/Servo Motor: LENZE (Germany); Inverter: DELTA (Taiwan); Photo Sensor: SICK (Germany); EPC: SELECTRA (Italy). You can add a 2-color/4-color in-line flexo printing machine. |

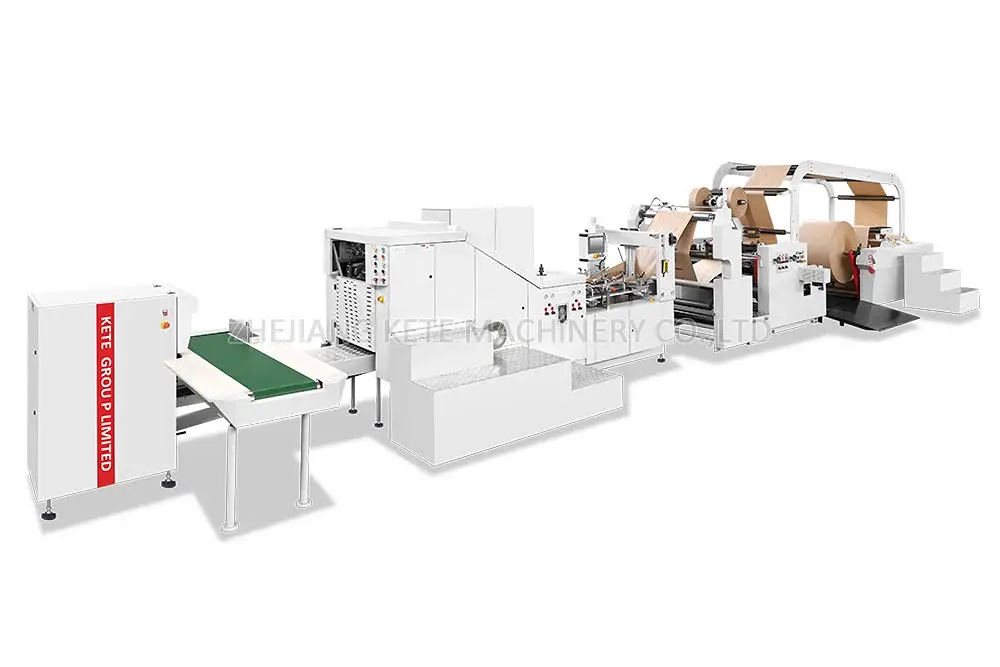

KTPM-BW Square Bottom Paper Bag Making Machine

Product Website: https://www.ketegroup.com/machine/square-bottom-paper-bag-making-machine/

- Key Advantages: This machine has high speed and works with small bags. The KTPM-BW can make up to 200 bags per minute. The bag width can be as small as 80mm, and the bottom as small as 50mm. It is great for making small square bottom bags. It has a plastic window option. You can choose to add a plastic window. This is good for showing the product inside. It works with many paper thicknesses. It can use thinner paper (40-150gsm), giving you more choices for production. KETE has over thirty years of making machines. This makes sure the machine is stable and strong. It also lowers long-term running costs.

- Reason to Recommend: If your main business is making general square bottom paper bags, especially if you need to make many small bags or bags with clear windows (like for food, stationery, toys), the KTPM-BW is a great choice. Its high speed and special features will help you do well in your market.

| Parameter/Feature | Description |

| Finished Bag Type | Square bottom paper bags with optional plastic window |

| Bag Width | 80-330mm (3.15”-13”) |

| Bag Bottom Width | 50-180mm (1.97”-7.1”) |

| Paper Thickness | 40-150gsm |

| Max. Bag Making Speed | 200 pcs/min |

| Paper Roll Diameter | Φ1200mm (47.2”) |

| Main Parts | PLC Touch Screen: SCHNEIDER (France); PC Motion Controller/Servo Motor: LENZE (Germany); Inverter: DELTA (Taiwan); Photo Sensor: SICK (Germany); EPC: SELECTRA (Italy). You can add a 2-color/4-color in-line flexo printing machine. |

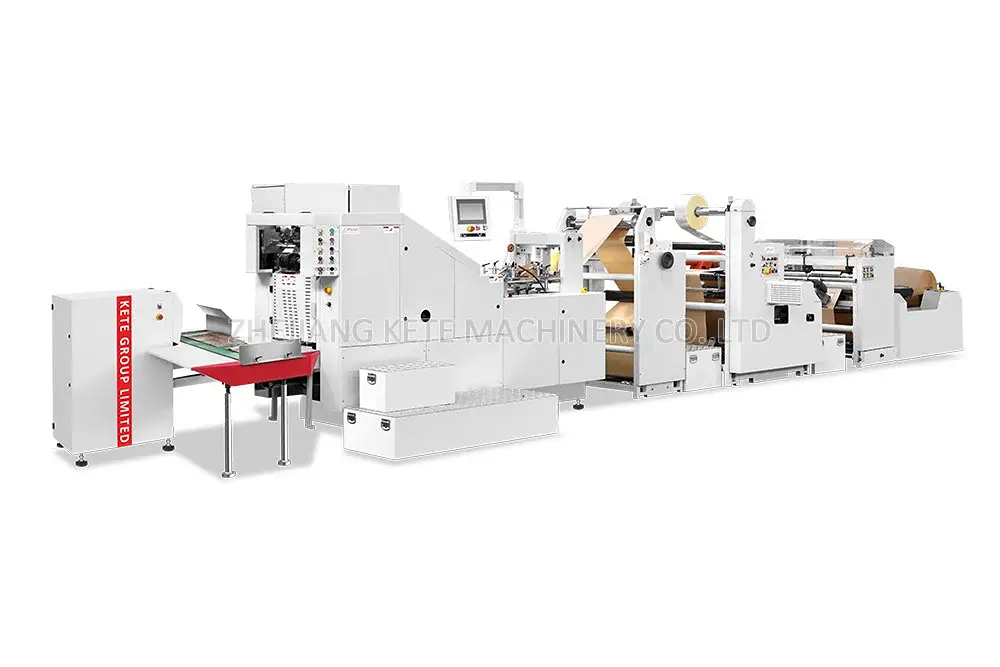

KTPM-BD Kraft Paper Bag Making Machine

Product Website: https://www.ketegroup.com/machine/brown-paper-bag-making-machine/

- Key Advantages: This machine is made for D-cut kraft paper bags. The KTPM-BD works well with kraft paper. It can make 150 bags per minute. It also makes D-cut handles well. This meets specific market needs. It is very adaptable. Paper can feed at up to 110m/min. This makes it more flexible. You can add a double unwind system for even faster production. KETE uses high-standard quality control. Checks are done many times during production. This makes sure every machine works well. It gives customers stable and reliable eco-friendly packaging.

- Reason to Recommend: More and more people want D-cut handle kraft paper bags. They are a stylish and eco-friendly packaging choice. The KTPM-BD is made for these bags. It can make these popular, eco-friendly products fast and well. It is a great choice for businesses that want to focus on the eco-friendly packaging market.

| Parameter/Feature | Description |

| Finished Bag Type | D-Cut square bottom paper bags |

| Bag Width | 190-450mm (7.5”-17.7”) |

| Bag Bottom Width | 60-180mm (2.36”-7.1”) |

| Paper Thickness | 50-150gsm |

| Max. Bag Making Speed | 150 pcs/min |

| Paper Feeding Speed | ≤110m/min |

| Paper Roll Diameter | Φ1200mm (47.2”) |

| Main Parts | PLC Touch Screen: SCHNEIDER (France); PC Motion Controller/Servo Motor: LENZE (Germany); Inverter: DELTA (Taiwan); Photo Sensor: SICK (Germany); EPC: SELECTRA (Italy). You can add a double unwind system or a 2-color/4-color in-line flexo printing machine. |

KTPM-A250 Paper Bag Making Machine

Product Website: https://www.ketegroup.com/machine/paper-bag-making-machine-for-sale/

- Key Advantages: This machine has very high production speed and is cost-effective. The KTPM-A250 can make up to 260 flat bottom bags per minute. This is a very fast solution for this type of bag. It also uses thinner paper (35-80gsm). This lowers material costs. The machine is small and does not take up much space. It is good for small and medium businesses or places with limited room. KETE’s great after-sales service means a 1-2 year warranty. They respond fast to problems. They offer on-site service when needed and spare parts. This gives customers full support. KETE’s technical innovation means most machines can update their systems online. This keeps the machine working its best.

- Reason to Recommend: If you have a small or medium business, or are new to making paper bags, the KTPM-A250 is a great start. It is flexible and easy to use. It has KETE’s usual high quality and full service. It can help you start your business well with less money at first. It is especially good for bakeries, pharmacies, and retail stores that need to make flat bags quickly.

| Parameter/Feature | Description |

| Finished Bag Type | Flat and Satchel Paper Bags |

| Raw Material Width | 160-780mm (6.3”-30.7”) |

| Bag Width | 70-250mm (2.76”-9.84”) |

| Bag Height | 105-455mm (41.3”-17.9”) |

| Paper Thickness | 35-80gsm |

| Max. Bag Making Speed | 260 pcs/min |

| Paper Feeding Speed | ≤70m/min |

| Bag Side Gusset | 20-120mm (0.79”-4.72”) |

| Bag Mouth Height | 15/20mm (0.6”/0.79”) |

| Main Parts | PLC Touch Screen: SCHNEIDER (France); PC Motion Controller: TRIO (UK); Servo Motor: YASKAWA (Japan); Inverter: DELTA (Taiwan); Photo Sensor: SICK (Germany); Unwind EPC: PASOURCE (Taiwan). You can add a film window opening device, film perforation function, double unwind system, or a 2-color/4-color in-line flexo printing machine. |

Tips for Starting Your Paper Bag Business

- Market Study: Learn a lot about what your market needs for paper bags. Look at sizes, types, printing needs, and what customers want.

- Business Plan: Make a clear plan for your business. Include money needs, how many bags you want to make, how you will sell them, and how you will make money.

- Get Materials: Find steady suppliers for paper. Make sure the paper is good quality and at a good price.

- Train Workers: Spend money on training your staff. Make sure they can use and take care of the machines well.

- Quality Check: Set up strong rules for checking quality. Make sure your paper bags meet industry rules and what customers want.

- Follow Rules: Know and follow local rules about packaging materials and making products.

How to Make Your Paper Bag Machine Last Longer

- Regular Upkeep: Follow the maker’s guide. Clean, grease, and check machine parts often.

- Use Original Parts: Use good quality original or suggested spare parts. This keeps the machine working right.

- Operator Training: Make sure workers are trained well. This stops them from breaking the machine by mistake.

- Control the Environment: Keep the work area clean, dry, and at the right temperature. Keep out dust and wetness to stop damage to the machine.

- Check Often: Have skilled people check the machine completely often. Find and fix problems before they get big.

Conclusion

The current situation with the paper bag business is that it has a great potential to grow due to environmental trends. The most important thing in taking advantage of this opportunity is to select the appropriate paper bag making machine to suit your business. KETE is a leading manufacturer. They possess more than thirty years of experience, excellent product quality, high automation, and complete global service. They are a reliable company to begin or expand your paper bag business. You can become a leader in the eco-friendly packaging market by making wise decisions and operating your business successfully. This will make your company successful forever.

Common Questions and Answers

- Is a paper bag machine a good investment?

Yes. People want more paper bags because of global environmental trends. Getting a paper bag machine can help businesses spend less, make more, and use the market chance for sustainable packaging. It is a good long-term investment for businesses that want to rely less on others, control quality, and react to market changes. - How much space do I need for a paper bag business?

The space you need depends on the type of paper bag machine you pick, how many bags you want to make, and if you need more room for storage or other work. Usually, a fully automatic paper bag machine needs a medium-sized factory space (like 50-200 square meters). This room is for the machine, holding raw materials, finished products, and working space. Bigger machines or more production lines need more space. - What are the most important things to consider when choosing a paper bag machine?

The most important things are your exact production needs (how many bags, type, size, and material), the machine’s level of automation and stability, and the seller’s after-sales service. Also, looking at the return on investment and your budget is very important. - Can one machine make different sizes or types of bags?

Most new paper bag machines are somewhat flexible. You can change parts or settings quickly to make paper bags of different sizes. But to make very different “types” of bags (like from a flat bottom to a square bottom, or no handles to with handles), you usually need different machine models or extra parts. Always ask the seller about the machine’s ability before you buy it. - Do I need special training to run these machines?

Yes. Even though new paper bag machines are more automatic and easy to use, you still need special training to run them. The maker usually gives training when they set up the machine. This makes sure your team can use the machine safely and well, and do daily care. - What other costs are there besides the machine’s price?

Other costs include: raw materials (paper, glue, etc.), electricity, worker wages (operators, maintenance staff), replacing spare parts and parts that wear out, regular maintenance and upkeep, and possibly factory rent and insurance.