Introduction

In the case of producing labels or packaging in large quantities, it is most effective to use a printing press, so the choice of technology is crucial. Earlier, choices were clear and few, but with the evolution of the sector, different techniques have come into existence and use. Both of them, flexographic and digital label printing are the most common, each having its advantages. Whether you are working on complex patterns, dealing with variable data, or producing short runs, it is important to understand these technologies to make the right choice for your production needs.

What is Digital Printing?

Digital printing is an advanced method of printing that delivers digital files like PDFs or images onto a press, skipping the conventional printing plates. It works through the use of ink or toner that is directly applied to a material through digital systems. This particularly reduces the time used to set up the machines, making production faster and more efficient than other forms of printing. It is most fitting for applications that need constant revisions or customized content, like changing barcodes, serial numbers, or designs for identification.

What is Flexographic Printing?

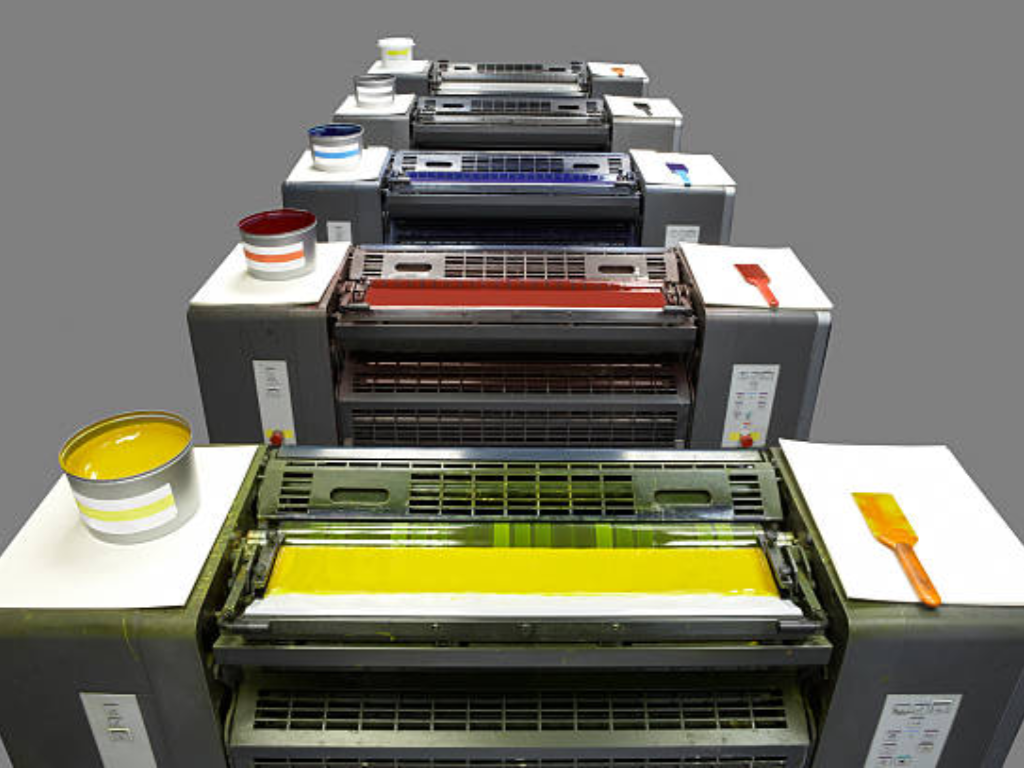

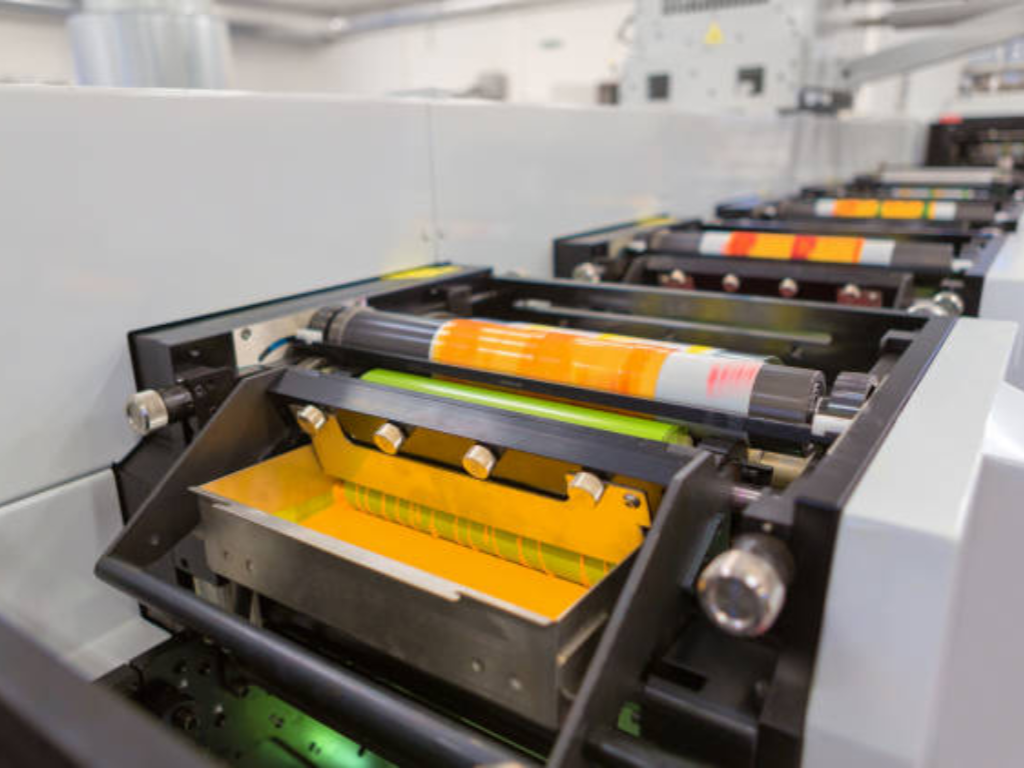

Flexographic printing also known as flexo printing, is a traditional printing method that uses flexible plates mounted on rotating cylinders in a flexographic printing press to transfer ink onto a variety of materials. The process starts with ink being applied from a reservoir to the printing plate, which then presses the design onto the substrate. Being one of the most effective and adaptable of printing, flexo printing is widely used in packaging, labeling, and many other areas.

Flexo Printing vs Digital Printing: What are the Differences?

The comparison between flexo printing and digital printing requires understanding factors such as consider key factors like image quality, material compatibility, production speed, cost, and environmental impact. In order to get a clearer picture of what each of these methods is capable of and what it is not, let us look at the main distinctions between these two types of printing.

| Comparison Factors | Digital Printing | Flexo Printing |

| Print Quality | High resolution (up to 2400 dpi), ideal for intricate designs | Lower resolution (300-600 dpi), better for simpler designs |

| Material Compatibility | Works on a variety of materials like paper, vinyl, foil, textured paper | Works well on thicker materials like corrugated cardboard and flexible packaging |

| Production Speed | Quick setup, ideal for small-batch production | Very high production speed (up to 600 meters/min), best for large-scale production |

| Cost | Low initial cost, ideal for short runs | High upfront cost (plate-making required) but lower unit cost for large quantities |

| Environmental Impact | Less material waste, no plate-making required | Can use eco-friendly inks and LED curing, but plate-making involves initial waste |

Print Image Quality Comparison

Digital printing is the best method of producing crisp high-quality images such sharp, high-resolution. When involved it is great for products with complex designs or that need vibrant colors such as custom labels or promotional items. It has a printing resolution of up to 2400 dots per inch which is impressive for producing fine text or pictures that contain complex graphics.

Flexo, in contrast, gives consistent results in bulk orders although it might lag behind for intricate designs. The resolution for flexo presses often ranges from 300 to 600 dots which is more than enough for packaging but might not be enough for the demands of fine art reproduction. That being said, plate-making technology has developed considerably and now Flexo gets to do more detailed designs. For example, flexo is most widely utilized in food packaging, where tough and bright prints are required for the materials to survive the bouncing around they will undergo while being transported and displayed.

Material Compatibility Analysis

One significant distinction between the two printing techniques is in their compatibility with materials. Digital printing is very flexible and can accommodate various materials such as paper, vinyl, foil, and the most recent being fabrics. Its versatility makes it applicable in projects whose materials are sensitive to frequent handling or that are generally not easy to handle. For instance, digital printing is always preferable for creating highly qualitative wine labels and especially for using them on textured or specialty papers.

Thus, flexo printing is used for industrial applications for which a certain degree of durability and large-volume production is preferred. It works very well on thick materials such as corrugated cartons and flexible plastics. Also, it is the most suitable method for producing plastic bags and shrink sleeves, which are popular in packaging due to their efficiency and ability to produce bright and durable colors on stretchable materials.

Production Speed and Efficiency

Flexo printing is the fastest and most scalable of all the printing techniques. Today’s flexo presses are capable of printing at speeds of up to 600 meters per minute and therefore are ideal for use in mass production. For example, printing 500,000 labels for a beverage firm can be done efficiently and at a low cost using flexo. It can run for long hours with few breaks. This makes it efficient, so it is ideal for large orders.

Digital printing, on the other hand, offers faster setup times. This is a process that just needs uploading a file and making little to no changes since there is no need for plates. This makes it ideal for small-scale projects and quick deliveries. For instance, it is possible to print 1,000 event badges with the recipient’s name on each badge in a matter of hours using a digital press. On the other hand, flexo would entail the need to make plates which may take days to prepare.

Cost Analysis

The cost-effectiveness of flexo and digital printing largely depends on the scale of the project. Flexo printing is relatively expensive in the initial stages because of the use of custom plates, which cost between $300 and $600 per plate. But for large volume jobs, the per-unit cost drops significantly. For instance, when using flexo printing to produce 100,000 product labels, the cost per label can be as low as $ 0.02 whereas the use of digital printing costs $ 0.10 per label, which makes flexo printing the most preferable for large quantities.

Digital printing, however, does not require plates as does conventional printing and is therefore more cost-effective for short press runs. For example, to print 500 custom stickers, it would cost between $150 to $200 with digital, while the extra plate cost for Flexo would bring the total to over $500. However, digital ink costs, which are usually 2 to 3 times more expensive than flexo ink, can turn into a problem for large orders, so it is not very effective for large-scale production.

Ideal Applications for Each Technology

Flexo printing and digital printing cater to different needs:

Digital Printing: Most appropriate for short runs, custom labels, and any application where the information on the labels will vary from one label to the next. It is particularly suitable for use in areas where fine detail and adaptability are critical.

Flexo Printing: Best suited for large-scale packaging, industrial labeling, and applications where the label has to be very tough, like shrink labels and cardboard boxes. Due to its high speed of production, it is suitable for large-scale production and hence cheap.

Environmental Impact and Sustainability

Both technologies are on the path to sustainability, but they are doing it in different ways. Digital printing is less wasteful than analog printing because it does not use plates and is sparing with materials in make-ready. In the short-run jobs, this can lead to the saving of up to 30% of the amount of material that would have been used in conventional printing.

Flexo printing, which was traditionally not very environmentally friendly, has become better. New water-based and UV-cured inks and recyclable substrates have been developed to minimize their impact on the environment. For instance, most flexo presses have adopted low-energy LED curing systems that are about 50% more energy efficient than the previous systems.

Finally, the choice depends on the requirements of the project that is being implemented. When evaluating print quality, compatibility of the material, speed, cost, and environmental impact, a business can match its printing strategy to its budget and goals.

How to Choose: Flexo vs Digital Printing for Your Needs

The selection of flexo and digital printing depends on your project needs, the scope of the project, the intricacy of your design project, your finances, and the compatibility of the materials. Here are the key factors to consider:

Project Size

For large-scale production, flexo printing is the cheaper method of the two. It has higher initial costs like the $300 – $600 of plates; however, its unit costs are cheaper than the other methods especially where runs are more than 10,000 pieces. Digital printing is most suitable for short runs because of the low setup time and cost involved.

Design Complexity

Digital printing is most beneficial where complex graphics are used and high resolution (up to 2400 dpi) is needed. This makes it the best choice for detailed artwork or personalized prints. Flexo, which runs at 300-600 dpi, is better suited for simpler designs but has been enhanced by the new plate-making technologies.

Material Compatibility

Digital printing is more suitable for your project if your substrates are sensitive, such as foil or specialty paper with texture. Flexo printing is particularly suited to thicker media than would be typical of corrugated cardboard or flexible packaging material.

Budget

Flexo is cheaper when used for large production, while digital printing is ideal for small production runs where initial costs have to be kept low.

Through such an assessment, you could choose a printing method that aligns with your project goals and budget.

Conclusion

Digital printing is best for quick turnaround and high degrees of detail for those small or detailed or custom jobs. Flexographic printing outperforms digital printing in long-run production where it offers unmatched efficiency and lower per-unit costs for larger orders. Both methods are compatible with a broad variety of materials and uses, and they are good at what they do in their respective specialties, flexo is the go-to if you are planning on using longer print runs for an extended period of time.

Ready to Invest in Flexo Printing Machines? Contact Us

As one of the leading manufacturers of flexo printing machines in China, we provide high-performance solutions tailored to meet diverse industry needs. KETE flexo printing machines are built for accuracy, durability, and speed, with production speeds of up to 250 meters per minute — boosting productivity by 50%. The flexibility of our customizable systems guarantees the quality of the outputs and enables businesses to market and defend their brands effectively.

Regardless of whether you are in the packaging, processing, or manufacturing industries, our machines could make your work easier through easy-to-use automation and minimal maintenance. Supported by ISO 9001, CE, and RoHS certifications, and 1-year warranty, we assure the quality and provide you with confidence.

Get in touch with us today and take your printing to the next level and achieve even more!