Introduction

When it comes to the world of food business, the price tag on packaging isn’t just about numbers. It’s the heartbeat of a brand’s survival. Product packaging serves as a critical interface between your brand and the consumer. It’s an engineered system designed to protect the product, communicate brand value, and drive purchasing decisions.. It’s a game-changer in your product’s journey, from keeping it fresh to making it irresistible to your audience. But here’s the twist: while packaging can dazzle, the price of packaging can also stack up, nudging your unit price. So, what’s the real cost of that handshake? Dive into this guide, and let’s unravel that mystery together. As manufacturers of the machinery that powers the packaging industry, we at KETE offer a unique behind-the-scenes look at what truly drives the final packaging price you pay.

The Great Food Packaging Showdown

Embarking on the food packaging odyssey? Brace yourself, because each choice comes with its own financial plot twist.

Plastic Containers: The lightweight champions of the packaging world. They’re often budget-friendly and can be a boon for your shipping costs. But, they might falter with heavier items, and let’s be honest, Mother Earth isn’t their biggest fan.

Cardboard Cartons: The versatile heroes. They’re often easy on the pocket and can be jazzed up with digital prints, though that jazz comes with its own price tag. While they’re feather-light, making shipping a breeze, they might not always be the guardians of food freshness.

Glass Bottles: The elegant aristocrats. They ooze premium vibes and are stalwarts in keeping your food pristine. But, their grace comes with a price, especially when you factor in shipping. They’re weighty and a tad delicate.

Different types of packaging choices are like a chapter in a story, influencing not just the narrative of your product but also the depth of your pockets. From the tales of raw materials to the epics of supply chains and the final curtain call of delivery, your packaging choice is the director of your budgetary play.

To give you a clearer financial picture, here’s a quick-reference table comparing common packaging types with their estimated unit cost ranges. These prices typically reflect a standard order quantity of around 5,000 units.

| Material Type | Common Use Examples | Pros | Cons | Est. Unit Cost Range |

| Corrugated Cardboard | Shipping Boxes, Mailer Boxes | Durable, protective, recyclable | Bulky, basic appearance unless printed | $0.50 – $3.00 |

| Folding Carton | Cereal Boxes, Product Boxes | Lightweight, highly printable | Less protective than corrugated | $0.30 – $2.00 |

| Rigid Box (Paperboard) | Luxury Goods, Gift Sets | Premium feel, extremely durable | Expensive, bulky to ship | $2.50 – $10.00+ |

| Flexible Pouch | Snacks, Coffee, Liquids | Lightweight, excellent barrier properties | Can feel less premium | $0.20 – $1.50 |

| Glass Jar/Bottle | Sauces, Beverages, Preserves | Premium, inert, recyclable | Heavy, fragile, high shipping cost | $0.60 – $2.50 |

| Plastic Container (PET, PP) | Takeout, Salads, Berries | Lightweight, versatile, cheap | Negative environmental perception | $0.20 – $1.00 |

Related Post: Types of Food Packaging: Leading Industry Suppliers Must Know

Factors that Impact Packaging Costs

Unraveling the mystery of packaging costs is like piecing together a jigsaw puzzle. Each component plays a role, and understanding each piece can help you see the bigger picture.

How Much Does Packaging Cost for Organic vs. Non-Organic Materials?

When it comes to packaging materials, there’s always a buzz around organic versus non-organic. But what does that mean to your wallet?

| Pros | Cons | |

| Organic Materials | They’re eco-friendly, often biodegradable, and can appeal to a niche market that’s willing to pay a premium for sustainable products. | They can be pricier. Whether it’s organic cotton bags or bamboo-based packaging, the raw material costs are often higher. |

| Non-Organic Materials | Typically more affordable. Plastics, certain cardboards, and other non-organic materials have been industry standards for years because of their cost-effectiveness. | They might not resonate with eco-conscious consumers. Plus, with increasing regulations around sustainability, relying solely on non-organic materials could be a risky long-term strategy. |

So, is organic always more expensive? Not necessarily. While the initial costs might be higher, the potential to tap into a market willing to pay more for eco-friendly products could balance out the scales. On the flip side, non-organic materials, while cheaper, come with their own set of challenges, especially in an era where sustainability is king.

Is Eco-Friendly Packaging More Expensive?

It is an age-old question: Is going green going to cost me more green? Eco-friendly packaging, with its biodegradable materials and sustainable production processes, seems like the future. But is it more expensive?

Initial Costs: Yes, materials like biodegradable plastics or recycled paperboard can come with a higher price tag initially. Custom printing on these materials? That’s another added cost.

Long-Term Benefits: However, there’s a silver lining. Brands that adopt eco-friendly packaging can market their products as sustainable, potentially attracting a larger customer base. Over time, this can lead to increased sales, offsetting the initial investment in eco-friendly packaging.

Regulations and Tax Benefits: Some regions offer tax incentives for companies that adopt sustainable practices. Plus, with stricter regulations around packaging waste, investing in eco-friendly packaging now might save you from hefty fines in the future.

In essence, while the initial packaging expenses of eco-friendly packaging might be higher, the long-term benefits, both in terms of brand image and potential financial incentives, can make it a worthwhile investment.

The Bulk vs. Boutique Dilemma

Ever stood at a crossroads, debating the merits of bulk buying versus purchasing just what you need? Packaging costs present a similar conundrum. At first glance, bulk orders seem enticing with their lower unit costs, and promising economies of scale. But the initial investment can be hefty, akin to stocking up on a year’s worth of gourmet coffee because it’s on discount. Do you have the capacity to store it all?

Conversely, smaller orders are like savoring a single artisanal chocolate bar. The per-item cost might be higher, but the financial commitment is manageable. Plus, it offers the agility to adapt to market shifts, refine designs, or pivot strategies.

The key? Striking a balance. It’s about harmonizing budget constraints, storage considerations, and market dynamics. While the allure of bulk orders is potent, sometimes the nimbleness of small runs offers invaluable strategic advantages.

This entire dilemma revolves around a core manufacturing principle: economies of scale. The reason bulk orders have a lower unit cost is because of significant one-time setup fees. For any custom packaging run, a supplier has to create custom printing plates and a cutting die (a tool that cuts the box shape). These fixed costs can range from $200 to over $1,000.

On a small order of 500 units, that $500 setup fee adds $1.00 to each box.

On a large order of 10,000 units, the same fee adds only $0.05 to each box.

Understanding this helps you see why your order quantity is the single most powerful lever you have for influencing your unit price.

The Art and Science of Graphic and Structural Printing

The Allure of Aesthetics

Ever been magnetically pulled towards a product on a shelf, even if it wasn’t on your shopping list? That’s the power of impeccable packaging. Those radiant colors, captivating fonts, and mesmerizing packaging designs are meticulously curated to captivate consumers. But such allure comes with its own price tag.

High-quality graphic reproduction is a function of precise machinery and material science. The final cost is a direct result of the manufacturing processes required. Every shade, every line, and every intricate detail is pivotal. Premium graphic printing ensures the vibrancy of colors, the clarity of text, and the precision of images. But achieving this artistry demands advanced digital printing technologies and specialized inks. Think of it as commissioning a bespoke artwork; the personalized touch is unparalleled but comes at higher printing costs.

Beyond Visuals: The Tactile Experience

Then there’s the structural dimension of packaging. It’s one thing for a package to be visually arresting, but it’s entirely another for it to offer a tactile delight. Those textured patterns, innovative folds, or unique openings elevate the unboxing experience. Crafting these tactile elements, however, is intricate. It demands specialized machinery and techniques, which, unsurprisingly, add to the expenditure.

In essence, while the charm of exquisite graphics and innovative structures is compelling, it’s crucial to weigh them against the associated costs. In the commercial arena, it’s a dance between creating a lasting impression and ensuring sustainable profitability.

A Practical Breakdown: In technical terms, the cost of “visuals” depends on:

Printing Method: Digital printing is ideal for short runs (under 1,000 pieces) as it has no plate setup fees. For larger jobs, Offset and Flexo printing offer a far superior per-unit cost.

Finishes: Each special finish—such as foil stamping or embossing—represents a separate pass through a specialized machine. This adds process time, labor, and tooling costs for each unit.

Insider Tip: The “specialized machinery” that creates these tactile experiences is key. A supplier’s cost for complex structures is directly tied to the precision and automation of their die-cutting and folder-gluer machines. Modern, efficient equipment (like the solutions KETE provides) minimizes waste and manual labor, making sophisticated designs more accessible and affordable for you.

The Hidden Costs of Quality Control and Testing in Food Packaging

Quality control in food packaging is a bit like that meticulous friend who double-checks everything before a big trip. Annoying? Maybe. Necessary? Absolutely. Ensuring that packaging meets all quality and safety standards is paramount. But this thoroughness, while invaluable, comes with its own set of costs that might not be immediately obvious.

Imagine launching a product only to recall it because of a packaging flaw. Nightmare, right? That’s where quality control steps in, acting as the guardian angel, ensuring every package is up to the mark. But this vigilance requires rigorous checks at various stages, specialized equipment, and a keen-eyed team. And time is money. The longer the quality control process, the higher the labor costs.

Then there’s the testing phase. It’s like the dress rehearsal before the big show. Before any packaging solution makes its debut on the market, it undergoes a series of tests. Durability tests, safety tests, stress tests – you name it. These tests ensure that the packaging can withstand real-world challenges, from rough handling during shipping to exposure to varying temperatures. But setting up these test scenarios, and sometimes even repeating them, can be a drain on resources.

In the end, while quality control and testing might seem like background processes, they’re front and center when it comes to costs. It’s a balancing act, ensuring top-notch quality without tipping the financial scales too much.

How Automation and Manual Labor Impact Pricing

There is an age-old debate: man versus machine. In the world of packaging, this debate takes on a whole new dimension. Do you rely on the precision of machines or the touch of human hands? It’s a bit like choosing between a handcrafted espresso and one from an automated coffee machine. Both have their merits, but they also come with distinct price tags.

With its whirring gears and blinking lights, automation promises efficiency. Machines don’t tire, and don’t take breaks. They churn out product after product with a consistency that’s hard to match. But here’s the catch: they come with a hefty upfront cost. It’s like buying a top-of-the-line smartphone; it might pinch your pocket now, but the features and longevity could make it worth the investment. Over time, automation can lead to significant savings, especially when you factor in reduced errors and increased output.

On the flip side, there’s manual labor. There’s something to be said about the human touch, the ability to spot anomalies, and the flexibility to adapt on the go. But humans, well, we have our limitations. We need breaks, we can make errors, and our pace might not match that of a machine. From a pricing perspective, manual labor might seem more affordable initially, but there are ongoing costs. Think about salaries, training, and the occasional downtime.

So, Which is the best option? It’s not a one-size-fits-all answer. Whether you lean towards automation or prefer the human touch, it’s essential to remember that both come with their own set of costs. It’s about understanding your production needs, gauging the scale of your operations, and then making an informed choice. And in the business game, it’s all about getting the best bang for your buck.

How Shipping and Logistics impact Packaging Costs?

Shipping is like planning a road trip. The destination, I mean the product in this case, is essential, but the journey? That’s where things can get messy.

Your choice of packaging can make a world of difference in shipping costs. Heavy items, fragile items, bulky packaging – they all add up. And let’s not even get started on international shipping. It’s like planning a trip abroad; the logistics can be a headache.

But here’s the kicker: sometimes, spending a bit more on durable packaging can save you in the long run. It is the best way. Think of it as investing in a good travel suitcase. It might be pricier, but it’ll save you the extra costs of product damage or lost goods.

The Cost of Meeting Food Safety Standards

Regulations are like that strict teacher you meet in school. You know, the one who seemed like they were nitpicking but was actually setting you up for success? Yeah, that’s what food safety standards are in the packaging world. They’re not there to make your life miserable; they’re there to ensure your product is safe and top-notch. But let’s not sugarcoat it; meeting these standards can feel like a trek up a mountain.

First of all, there’s the paperwork. It’s like doing your taxes but for your product. You’ve got to prove that your packaging is up to snuff, and that often involves tests, certifications, and maybe even a lawyer or two. And let’s be honest, none of that comes cheap.

Then there are the actual changes you might have to make to your packaging. Maybe you find out the ink you were planning to use isn’t food-safe, or the plastic has some issues. It’s like planning a road trip and realizing halfway that your car needs new tires. Unplanned, but necessary.

And don’t even get me started on international standards. If you’re planning to sell your product overseas, you’ve got a whole new set of rules to follow. It’s like learning the local customs and language before a trip; it takes time and effort, but it’s crucial.

So, is regulatory compliance a pain? Absolutely. But is it necessary? Even more so. It’s the packaging charges of doing business, and trust me, it’s a lot cheaper than the cost of a recall or a tarnished brand reputation.

Tips for Optimizing Your Food Packaging Budget

Here are five concrete strategies that can directly reduce your packaging expenditures:

Streamline Your Structural Design

Before you even think about colors, focus on the physical shape. Complexity costs money. A simple, standard-shaped box is always cheaper than a custom, intricate one.

Why it saves money: Complex designs with unique folds, tabs, or windows require custom cutting dies, slower machine speeds, and sometimes manual assembly—all of which drive up labor and setup costs.

Actionable Step: Challenge your designer with this question: “Can we achieve a premium unboxing experience using a simpler, more standard box structure?” Often, a standard mailer or folding carton with great graphic design is more effective and far cheaper than a complex custom shape.

Be Strategic with Printing and Finishes

This is where budgets can spiral. While beautiful, every special finish is another process, adding another layer of cost.

Why it saves money: Each color in a print job can require a separate printing plate and machine pass. Finishes like foil stamping, embossing, or spot UV are entirely separate processes with their own setup fees.

Actionable Step:

Reduce Colors: Can your design work with 2 or 3 Pantone colors instead of full 4-color (CMYK) process? This can lead to significant savings on large offset or flexo runs.

Prioritize One “Wow” Factor: Instead of using foil, embossing, and a special laminate, choose the single most impactful finish for your brand and eliminate the others.

Leverage Standard Sizes to Eliminate Tooling Costs

This is one of the most overlooked but effective cost-saving tips. Every custom-sized box requires a custom cutting die, which is a one-time fee that can cost $300 to $1,000+.

Why it saves money: By using a “standard” size that the packaging supplier has already created for other clients, you completely avoid the cost of creating a new cutting die.

Actionable Step: Before finalizing your product dimensions, ask your potential suppliers for a list of their standard or house die-lines. Adjusting your product’s fit by a quarter-inch to match an existing die can save you hundreds of dollars instantly.

“Right-Size” Your Material Thickness

It’s tempting to choose the thickest, most robust-feeling paperboard, but it’s often overkill. Using more material than necessary is like paying for extra features you don’t need.

Why it saves money: Material is a primary cost driver. Moving from a 24pt paperboard to an 18pt board for a lightweight product (like tea bags or cosmetics) can reduce your material costs by 25% without compromising the needed protection.

Actionable Step: Tell your supplier exactly what product is going inside and its weight. Ask them for a recommendation on the most cost-effective material thickness that will still provide adequate protection and a quality feel.

Partner with a Technologically Advanced Supplier

This final tip underpins all the others. The efficiency of your supplier’s factory directly impacts the price you pay.

Why it saves money: A supplier who has invested in modern, automated equipment (like the high-speed printing and converting solutions KETE provides) has lower labor costs, less material waste, and faster setup times. These efficiencies translate directly into more competitive pricing for you.

Actionable Step: When vetting suppliers, don’t be afraid to ask: “What kind of technology do you use for printing and box converting? How does your level of automation help keep my costs down?” A confident answer is a very good sign.

Design for Shipping Efficiency

An often-overlooked cost is not the package itself, but the price of shipping it once your product is inside. Modern logistics companies charge based on “dimensional weight,” which means the amount of space a box takes up is just as important as its actual weight.

Why it saves money: Reducing empty space inside your package by even 10% can lower your shipping costs on every single unit you send. Additionally, designing boxes that can be shipped flat to your warehouse (and assembled by you) dramatically reduces inbound freight costs.

Actionable Step: Ask your packaging supplier: “How can we design this to minimize dimensional weight?” and “Can this box be engineered to ship to us flat-packed for easy assembly?”

You May Like: Top 10 Packaging Machine Manufacturers Worldwide

Putting It All Together: How to Get an Accurate Quote

This is your RFQ (Request for Quotation) Checklist.

Packaging Type & Style

Be as specific as possible. Instead of “a box,” say “a roll-end tuck-front mailer box” or “a stand-up pouch with a zipper.”

Example: Roll-End Tuck-Front (RETF) Mailer Box

Interior Dimensions (L x W x H)

Measure your product first, then add a small amount of clearance (e.g., 1/8 inch or 3mm) on each side for a good fit. Providing interior dimensions is the industry standard.

Example: 9″ (L) x 6″ (W) x 2″ (H)

Material Specifications

Reference the materials table earlier in this guide. The more specific, the better.

Example: E-flute Corrugated Cardboard, Kraft Brown exterior, White interior.

Printing Requirements

Colors: Specify the number of colors. If you know the specific color codes (e.g., Pantone 185 C or “CMYK process”), include them.

Finishes: List any special finishes you require.

Example: 2-color print on the exterior (Black and Pantone 185 C), with a Matte Lamination.

Quantity

This is crucial. To understand the economies of scale, ask for pricing at multiple quantities. This gives you insight into where the price breaks are.

Example: “Please provide pricing for quantities of 1,000, 2,500, and 5,000 units.”

Your Artwork or Dieline (If Available)

If you have a design file or a dieline from a designer, attach it to your request. If not, simply state that you will need a dieline created based on your requested dimensions.

With this checklist, you are not just asking “how much?”; you are providing a detailed project scope. This will ensure you receive faster, more accurate quotes and immediately establish you as a knowledgeable and professional client.

How Much Does Packaging Cost for Frozen Foods vs. Fresh Produce?

Packaging plays a pivotal role in the food industry. Different products have unique needs, and understanding these can significantly impact costs. Let’s dive into a comparison between frozen foods and fresh produce to see how their packaging needs differ and what that means for your bottom line.

Frozen Foods

Materials and Durability: Frozen foods require robust packaging. They need to withstand cold temperatures, resist moisture, and prevent freezer burn. This often means multiple layers and special seals, sometimes even vacuum packing.

Visibility and Presentation: Consumers like to see what they’re buying. Clear packaging or a windowed design is common, but it also needs to maintain its clarity in freezing conditions.

Cost Implications: The specialized needs of frozen foods mean higher costs. It’s an investment in ensuring the product remains in optimal condition from the factory to the freezer.

Fresh Produce

Materials and Breathability: Fresh produce needs packaging that allows it to breathe. This often means lighter materials with perforations or mesh designs.

Protection and Presentation: Fresh produce is delicate. The packaging must protect items from bruising while showcasing their freshness. Think of clear clamshell containers for strawberries or cushioned cartons for tomatoes.

Cost Implications: While the materials for fresh produce might be less expensive than those for frozen foods, the need for protective and breathable designs can add to the costs. However, effective packaging can reduce waste due to damaged goods, balancing out expenses in the long run.

Future Trends: How Sustainability and Technology Will Affect Costs

The packaging industry is at a crossroads, with sustainability and technology steering its direction. As the global community becomes increasingly eco-aware, the clamor for green packaging solutions grows louder. But this environmentally-friendly transition isn’t without its financial implications.

Sustainable packaging, which leans heavily on biodegradable or recyclable materials, is gaining traction. These materials, while fantastic for our planet, can initially be more expensive due to production complexities and growing demand. However, as more manufacturers jump on the sustainability bandwagon, economies of scale might eventually bring costs down.

On the other hand, technology is revolutionizing packaging in ways we hadn’t imagined a decade ago. Smart packaging, which can interact with consumers, and augmented reality experiences are becoming more prevalent. These tech-driven solutions can enhance user experience but come with their own set of costs. Investing in technology might be pricier upfront, but the potential for brand differentiation and customer engagement can offer long-term returns.

In essence, while both sustainability and technology might increase packaging costs in the short term, they represent investments in the future – a future where brands resonate more deeply with informed and tech-savvy consumers.

The Grand Finale: How KETE’s Packaging Machines Harmonize Cost and Quality

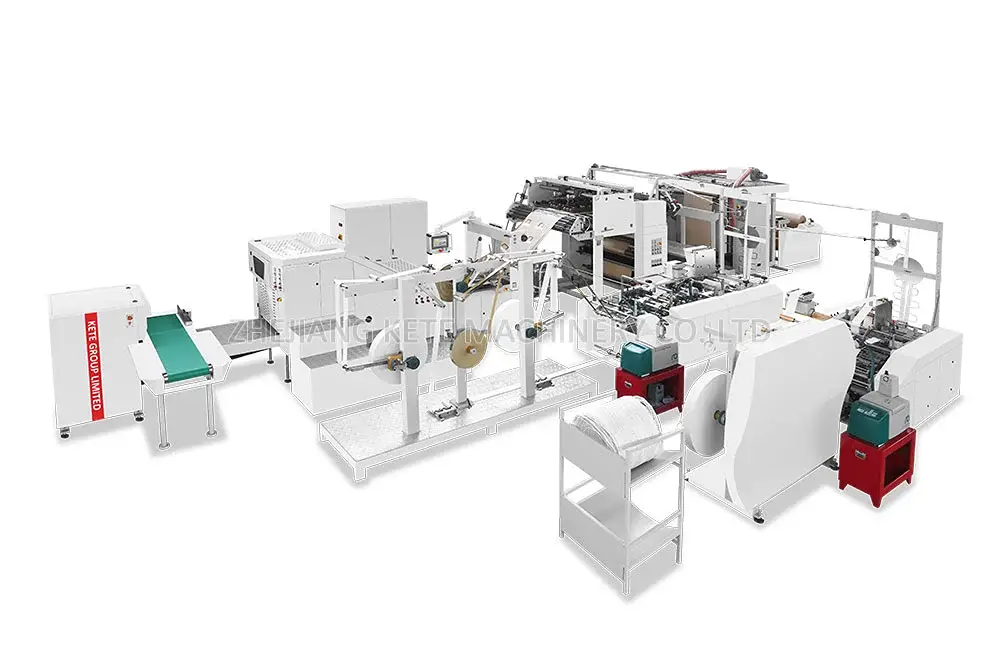

Ultimately, controlling packaging costs comes down to controlling the efficiency of the production line. At KETE, we engineer the solutions that give packaging converters that control. From high-speed Flexo Printing Machines that ensure color consistency at scale, to automated Paper Bag and Pouch Making Machines that reduce manual labor and material waste, our role is to provide the technological foundation for cost-effective, high-quality packaging.

Investing in a packaging supplier who leverages this level of production technology is not just a purchasing decision; it’s a strategic move to de-risk your supply chain and ensure long-term cost predictability.

The Final Note

Navigating the labyrinthine world of packaging costs can feel like a daunting odyssey. Yet, much like an experienced explorer with a well-drawn map, understanding the terrain makes the journey less intimidating. In a world where sustainability and technological innovation set the stage, challenges transform into opportunities.

By tuning into the innovative solutions orchestrated by companies like KETE, businesses can not only meet the evolving market demands but also fine-tune their cost structures. It’s about hitting the perfect note—a balance between quality, efficiency, and budget.

In the grand scheme of things, effective packaging is more than just a container; it’s a crescendo in your brand’s symphony, reflecting its values, its promise to consumers, and its adaptability in an ever-changing marketplace. By staying in tune with the latest trends, leveraging cutting-edge tools, and embracing innovation, businesses can ensure their packaging not only steals the show but also makes sound financial sense.

FAQS

Q: What is the average packaging cost?

A: The average packaging cost varies depending on the type of product, the materials used, and the size of the business. On average, packaging costs can range from $0.50 to $5.00 per unit for small to medium-sized businesses. Factors such as custom packaging, shipping requirements, and product fragility can significantly affect the price.

Q: How do you calculate packaging cost?

A: To calculate packaging cost, you need to add up the cost of materials, labor, and any overhead related to the packaging process. The formula is:

Packaging Cost = Cost of Materials + Labor Costs + Overhead Costs + Shipping Costs (if applicable)

For example, if the cost of the box is $0.50, the tape costs $0.10, labor costs are $0.30, and shipping is $2.00, the total packaging cost per unit would be $2.90.

Q: How much does packaging cost for a small business?

A: For a small business, packaging costs can vary significantly depending on the product type, shipping volume, and whether the packaging is custom. On average, packaging can account for 10% to 20% of the product cost. For example, if your product costs $20 to manufacture, packaging could add an additional $2 to $4 to each unit.

Q: Is packing cost a selling cost?

A: No, packing cost is generally not considered a selling cost. Selling costs are typically related to activities directly associated with the sale of a product, such as advertising, commissions, and distribution costs. Packing costs are more closely related to production or fulfillment costs, as they involve preparing the product for sale and shipment. However, in some cases, packing costs can be considered part of the overall cost of goods sold (COGS).