Printing technology has evolved drastically over the years, from the meticulous hand-crafting of movable type to the speed and precision of modern digital presses. The printing press, ever since Johannes Gutenberg’s revolution in the 15th century, has been integral to the dissemination of knowledge. Today, as we navigate through the diverse needs of the printing industry, we’re graced with an array of printing presses each designed to meet specific printing needs. Whether it’s for commercial printing of business cards or large volume productions for marketing materials, the printing press types available mirror the vastness and versatility of the industry itself.

In this section, we’ll dive into the varied world of printing presses, laying bare their mechanics, features, benefits, the specific niches they best serve and how to choose the right printing press for your project. The essence of quality printing lies not only in the skills of the printer but also in the technology employed, so understanding the different types of printing presses is crucial for anyone involved in this dynamic industry.

| Type | Key Features | Cost Profile | Ideal Volume / Run Length | Quality & Finish | Common Applications | Key Limitations |

| Offset | Image transferred via plates & rubber blanket | High setup cost, very low unit cost at high volume | Medium to high volume (500+) | Sharp images, excellent color fidelity (Pantone), consistent quality | Books, magazines, brochures, posters | No variable data, slow setup, not economical for short runs |

| Digital | No plates needed; prints directly from a digital file | No setup cost, consistent unit cost | Low to medium volume (1-1000) | Good quality, ideal for Variable Data Printing (VDP) | Business cards, personalized mailers, menus, on-demand printing | Higher cost for long runs, spot color matching can be less precise than offset |

| Flexography (Flexo) | Flexible relief plates and fast-drying inks | High setup cost, extremely low unit cost | High to very high volume (10,000+) | Versatile on various materials, halftone dots can be less fine | Packaging, labels, plastic bags, corrugated cartons | Complex and expensive plates, not ideal for photo-realistic images |

| Gravure | Image engraved onto a cylinder | Extremely high setup cost, extremely low unit cost | Very high volume (100,000+) | Premium quality, rich color depth, perfect detail | High-end magazines, postage stamps, premium packaging, cigarette packs | Highest plate-making cost, long lead times, only feasible for massive runs |

| Screen Printing | Ink is pushed through a mesh stencil onto the substrate | Medium setup cost, moderate unit cost | Low to high volume | Thick, opaque ink layer with vibrant colors | T-shirts, tote bags, posters, signage | Limited detail and color gradients, not for complex images |

| Letterpress | A raised, inked plate is pressed into the paper | High setup cost, low production efficiency | Low volume (artisanal) | Unique debossed texture, elegant and handcrafted feel | Invitations, greeting cards, business cards, art prints | Slow, expensive, cannot reproduce large solid blocks of color smoothly |

| UV Printing | UV light is used to cure ink instantly | Higher cost per print, but no coating needed | Low to high volume | Vibrant colors, strong adhesion, slight raised feel | Signage, premium packaging, non-absorbent materials (e.g., plastic, metal) | Higher ink and equipment costs compared to conventional inks |

| Large Format | Inkjet technology used to print oversized graphics | Priced per sq. meter, high unit cost | On-demand single pieces or small batches | High resolution, strong visual impact | Banners, posters, vehicle wraps, interior decor | Relatively slow printing speed, not suitable for high-volume, small-item jobs |

| Dye Sublimation | Heat turns ink into gas to infuse it into the material | Moderate equipment and consumable costs | Low to medium volume | Color becomes part of the substrate; no feel, very durable, washable | Apparel, mugs, mousepads, flags | Limited to light-colored polyester fabrics or polymer-coated hard surfaces |

| 3D Printing | Builds a three-dimensional object layer by layer | High cost, priced by material and time | Single pieces or small batch prototypes | Precision and surface finish vary by technology | Prototypes, custom parts, models, medical implants | Extremely slow, limited material selection, high cost per part |

Flexographic Printing Machines

Flexographic printing, commonly known as flexo, is one of the most rapidly developing and versatile of the printing processes. This type of printing process is often used for high-volume runs, and it is particularly well-suited for packaging materials—a segment where it holds an immense popularity.

Flexography is a form of rotary web letterpress, combining features of both letterpress and rotogravure printing. It utilizes flexible photopolymer printing plates, which are wrapped around rotating cylinders on a web press. The inked plates with a slightly raised image are rotated at high speeds to transfer the image to the substrate. A key aspect of flexo lies in the fast-drying inks used, which are usually water-based or UV-curable, making the process suitable for a range of non-porous and porous substrates.

Flexographic printing machines are engineered to accommodate a variety of printing needs and can handle substrates of different thicknesses and uneven textures—ranging from fine paper to heavy corrugated fiberboard. One of their defining features is the use of the anilox roll, which plays a crucial role in transferring a precise layer of ink onto the printing plate. The anilox roll features hundreds of thousands of tiny cells that deliver a consistent amount of ink to the plate and ultimately the substrate, enabling high-quality and uniform printing results.

Moreover, the modern flexo machine is equipped with advanced control systems to fine-tune the print register and color consistency, ensuring high-definition images and clean lines. As technology advances, these machines become more automated, providing faster setup times and improved printing capabilities that can challenge the dominance of lithography in print quality.

The critical engineering challenge in high-speed flexo is precise ink metering to control dot gain. The sophistication of the anilox roll’s cell structure and the stability of the central impression drum are what truly separate a standard press from a high-performance modern printing machine capable of handling thin, challenging films.

Related Post: Flexo Press Demystified: A Beginner’s Guide to the Printing Process

Advantages and Considerations of Flexographic Printing

Flexographic printing machines provide multiple advantages, making them a great option for various applications. One critical advantage is their speed and ability to produce large volumes rapidly—it’s the ideal technology for packaging that requires long runs, such as plastic bags and milk cartons. Due to the nature of the inks and speed of the drying process, flexo printing allows for quicker turnaround times compared to traditional printing methods.

Another significant benefit of flexo is its environmental edge—the process usually generates less waste and uses inks which can be more environmentally friendly, especially when water-based inks are chosen.

However, the initial setup cost for a flexographic press can be substantial. Creating custom printing plates and configuring the machine for specific print jobs may also be time-consuming and is more cost-effective when distributed over larger print runs.

Applications of Flexographic Printing

Flexographic printing is highly adaptable and can be used for a wide array of products. This includes food packaging, beverage cartons, wallpaper, and even laminates for flooring. Specialty tags and labels—ranging from simple stickers to complex security tags—are also well within flexo’s realm.

The technology supports printing on various substrates, such as paper, foils, films, and non-wovens, making flexo machines suitable for packaging and decor applications. Companies in the fast-moving consumer goods sector often rely on flexography for their packaging due to its adaptability, print quality, and efficiency.

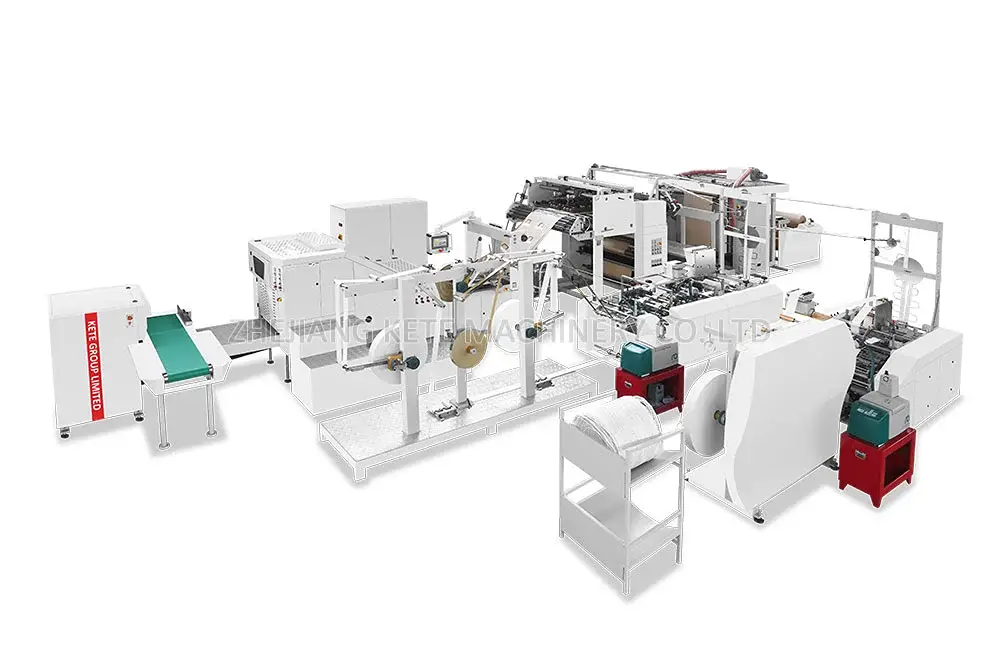

If you’re on the hunt for a quick, secure, and dependable flexo printing machine, take a moment to explore what KETE GROUP LIMITED has on offer. With an array of flexo machines at your disposal, such as CI, Stack, and In-Line models, KETE GROUP LIMITED ensures you’ll find the perfect fit for any project you have in mind. Plus, with dedicated label printing equipment, KETE GROUP LIMITED is committed to delivering one of the greenest printing options out there today.

You May Like: Industry Leaders: 5 Flexo Printing Machine Manufacturers Revolutionizing Printing

Rotogravure Printing Machines

Rotogravure printing, also known simply as gravure, is one of the oldest printing techniques that remains widely used in high-volume production today. The core of this printing technology lies in its ability to achieve fine detail and consistent high quality, which is why it is favored for a variety of high-impact, large-circulation print products.

The gravure process works by directly transferring ink from etched cells on a cylinder to the substrate. Unlike other printing methods that simply apply ink to the top surface of the printing plate, rotogravure cylinders actually contain the image etched below the surface in the form of cells. These cells vary in depth, and the volume of ink they hold determines the intensity of the color printed.

Rotogravure printers are engineered for precision and speed, making them a premium choice in the industry. They typically consist of an engraved cylinder, doctor blade, inking system, and impression roller. The engraved cylinder rotates through the ink fountain where the recessed cells fill with ink. The doctor blade then scrapes off the excess ink from the non-image areas, and the substrate is pressed against the cylinder by the impression roller, transferring the image.

Modern gravure presses can have multiple printing units for different colors, which is why it’s possible to print intricate, multi-colored designs at high speeds. Achievements in electronic engraving have also allowed for finer cell structures and quicker production times of cylinders, leading to improved image quality and reduced costs in cylinder preparation.

The unparalleled quality of gravure comes from its direct, variable-depth ink transfer from engraved cells, allowing for a superior tonal range. Consequently, a key focus in modern press design is the advanced electrostatic assist (ESA) system, which ensures flawless ink release from the cells onto challenging substrates.

Benefits and Challenges in Rotogravure Printing

The primary strength of gravure printing is the exceptional print quality it can achieve, which includes sharpness, color consistency, and image clarity. This, combined with its unparalleled speed, makes gravure an ideal choice for large quantities of printing, where quality cannot be compromised—such as in high-end catalogs, glossy magazines, and sophisticated packaging.

One consideration for the gravure process is the significant initial cost for the cylinders since each new image requires a new cylinder. However, these cylinders are extremely durable, allowing millions of impressions to be made before needing replacement. As a result, the higher initial costs can be spread over long runs, making the cost per page highly competitive for high-volume jobs.

Rotogravure Printing in Modern-Day Applications

The advanced capabilities of rotogravure make it particularly suitable for printing on thin films used in product packaging—everything from food and pharmaceuticals to cosmetics and tobacco. Because of its precision, it’s also widely employed in the production of printed wallpapers, laminates, and transfer printing, which demands high aesthetic quality.

If you’re gearing up to launch a large-scale printing operation and need a top-notch gravure printing machine, look no further than KETE GROUP LIMITED as your go-to ally. Tackle bigger jobs, ramp up productivity, and cut down on expenses. Our cutting-edge technology is designed to deliver exceptionally high-quality color renditions, perfect for upscale packaging, from jewelry boxes to milk cartons. Whether you’re interested in a 2-color, 4-color, 6-color, or 8-color gravure printer, rest assured that the consistent quality of the print packaging you provide will be something your clients will notice and value.

Digital Printing Presses

Digital printing is the cornerstone of modern printing methods, allowing for high-quality prints with quick turnaround times. Digital printers, including those used for digital photo printing and commercial use, function without the traditional use of printing plates. Instead, they rely on digital files such as PDFs, which are sent directly to the digital printing machine. This method offers unparalleled flexibility for individual customers and business needs, suiting small to medium print jobs that require a great option for quick response and a variety of substrates.

Ideal for various applications, digital printing machines support a wide range of materials, from paper to fabrics and even ceramics. Think about the last business card you received; it was possibly produced on a digital printing press, which highlights the meticulous detail and vibrant colors that can be achieved. The unique use of digital presses in creating personalized items or small runs of prints is why they have gained immense popularity across different types of products.

The conversation around digital has shifted from simply enabling short runs to ensuring absolute color consistency across jobs. The core engineering priority is now closed-loop color management and workflow automation, allowing digital presses to seamlessly integrate into, and even rival, traditional offset environments for quality.

Screen Printing Presses

Screen printing presses use a woven mesh to support an ink-blocking stencil. The stenciled design forms open areas of mesh that transfer ink or other printable materials, which can be pressed through the mesh as a sharp-edged image onto a substrate. This type of printing press machine is particularly well-suited for rendering high-quality artistic and commercial graphics on various materials, from t-shirts to billboards.

Screen printing’s versatility with different printing methods has made it a favorite for screen printers specializing in unique designs on fabric and other materials. It allows for high-quality prints on vast numbers of items, often proving cost-effective for larger quantities. Whether you’re wearing a printed t-shirt or using a mouse pad, screen printing has likely played a part in creating those items.

Achieving sharp, high-opacity screen prints is a science of mechanical precision. The key variables we engineer for are consistent mesh tension and computer-controlled squeegee pressure and angle, as these factors directly determine ink deposit and edge definition.

Offset Printing Presses

Offset printing, also known as offset lithography, is one of the most common methods of mass-production printing. Its primary advantage is the consistent high image quality and cost-effectiveness at large volume.

An offset press uses a printing plate that holds the image to be printed. The plate transfers, or ‘offsets,’ the image onto a rubber blanket and then to the printing surface. The process relies on the repulsion of oil and water, with the image receiving ink from ink rollers, while the non-printing area attracts a water-based film, keeping it free of ink.

Commercial printing needs, including large runs of magazines, books, and marketing materials, often utilize offset presses. For a print job that demands large quantities with great color fidelity and detail, offset printing is a stalwart choice.

While offset’s principle is classic, the modern engineering battleground is in reducing makeready waste and time. Advanced systems now feature automated plate changing and in-line spectrophotometers that bring a press to precise color standards in a fraction of the time, dramatically increasing job-to-job profitability.

Letterpress Printing Machines

Letterpress printing is a technique of relief printing that uses a printing press and movable type, where a raised surface is inked and then pressed into a sheet of paper.

With its roots in the earliest days of printing, letterpress machines are enjoying a resurgence for greeting cards, invitations, and other forms of fine printing solutions. It creates an elegant, tactile impression on the paper, a niche that modern technologies simply cannot replicate authentically.

The individual nature of the setup process and the characteristic impression made on the paper gives letterpress a unique, handcrafted feel that’s highly sought after for special occasions and art prints.

For modern letterpress, the engineering focus has shifted from speed to precision control. The goal is to provide artisans with meticulous control over platen pressure and roller height, allowing them to achieve everything from a delicate ‘kiss’ impression to a deep, tactile bite with repeatable consistency.

Inkjet Printers

Unlike traditional printing presses, inkjet printers operate without the need for printing plates or lengthy setup times. These versatile devices create images by dropping spots of ink onto a variety of substrates.

Inkjet printing technology shines in its ability to handle a diverse range of printing jobs—from the simple printing of documents and photos to wide-format models used in printing house banners and signage. They offer a digital printing methodology that combines quality printing with a quick turnaround, suitable not just for businesses but also for individual customers.

While not typically associated with high-volume printing needs, inkjet printers excel in producing vibrant and detailed high-quality images, especially beneficial for marketing materials and fine-art reproductions.

The sophistication of an inkjet system lies in its printhead technology and ink chemistry. Advanced printheads now offer variable drop sizes for smoother gradients, while UV-curable and latex-based inks have expanded inkjet’s capabilities far beyond paper to rigid and flexible industrial materials.

Laser Printers

Laser printers are a mainstay on office desks and in print shops, valued for their fast printing speed and sharp text quality. Utilizing a laser beam, they provide an electrostatic digital printing process.

The process of laser printing involves using a laser to form a static charge on a drum that attracts and then transfers toner particles onto paper. It’s a great option for quick turnaround times and is known for yielding highly precise prints, making it ubiquitous with professional and marketing materials that require clean, crisp font rendering.

While laser printers may not be the go-to for large volume, image-heavy projects, they are invaluable for business and individual customers needing reliable, quality document printing with a fairly low cost per page.

The core of a production-level laser printer’s performance is its fuser technology and toner formulation. These elements dictate not only speed but also the ability to maintain consistent gloss levels and bond toner effectively to a wide range of specialty papers and synthetics without curling or cracking.

3D Printers

3D printers are reshaping the concept of printing by turning digital models into three-dimensional objects. This technology is not just a printing process; it’s an additive manufacturing process.

These printers work by layering materials—like plastics, resins, or even metals—to build objects from the bottom up. Industries from medicine to aerospace are leveraging 3D printers for their uniquely practical application of digital files to tangible, functional products.

The ability to create models, prototypes, or parts with complex geometries effectively and affordably makes 3D printers an essential tool in modern product development and small-scale manufacturing.

Beyond just building shapes, the true industrial value of 3D printing is found in material science and repeatable dimensional accuracy. The engineering challenge is ensuring that a part printed today will have the exact same mechanical properties and tolerances as one printed six months from now.

Thermographic Printers

Thermography is a printing process that creates raised images on paper and other substrates, typically used for business cards, letterheads, and other stationeries where a textural element can heighten the impression.

Through a post-printing process where a resinous powder is added to wet ink and then heated, prints come to life with a distinctive, tactile dimension. It’s a cost-effective way to achieve a similar look to engraving, commonly used to provide a heightened level of sophistication on printed materials.

The elegant finish provided by thermographic printers is synonymous with high-quality, professional prints and is especially popular for adding a touch of class to corporate branding materials.

While a simple process, the quality of thermography is determined by the uniformity of the heat application and the quality of the resinous powder. Uneven heating can lead to a mottled or incomplete gloss, which is why professional systems utilize precise infrared heaters for a consistent, high-end finish.

Pad Printers

Pad printing is a printing process that can transfer a 2-D image onto a 3-D object. This is accomplished using an indirect offset (gravure) printing process that involves an image being transferred from the printing plate via a silicone pad onto a substrate.

Pad printing is unique in its ability to print on very uneven surfaces. It’s ideal for objects like toys, medical products, electronics, and automotive components which often have complex shapes. The silicone pad molds itself to the shape of the object, allowing for precise and detailed printing on areas that are difficult to reach.

Due to its versatile printing method, pad printers are a preferred choice in the manufacturing industry. They can handle various materials and surfaces, such as plastics, metals, ceramics, and silicone. This makes them indispensable for signage, electronic devices, and custom promotional products.

The magic of pad printing is in the formulation of the silicone pad and the ink’s solvent system. The pad’s ability to conform to a shape while cleanly releasing the ink film is a delicate balance of material science that enables printing where other methods are impossible.

Dye Sublimation Printers

Dye sublimation printers are a specialty printer type that uses heat to transfer dye onto materials such as plastic, card, paper, or fabric. The main difference between this and other types of printing is that dye sublimation creates a gradual blend between colors, making it perfect for photographic images and vibrant designs.

With dye sublimation, the level of detail and range of color is immensely superior to some other printing methods. The images produced are less prone to fading and distortion over time. This makes dye sublimation printers perfect for high-quality graphic displays and apparel.

The technology is widely used for producing personalized items or promotional goods due to its ability to print intricate, full-color designs. Items like mugs, mouse pads, and garments frequently employ dye sublimation for a long-lasting and visually striking finish.

Consistent and accurate color in dye sublimation is entirely dependent on precise heat and pressure control across the entire platen. Any temperature fluctuation, even a few degrees, can cause noticeable color shifts, making thermal consistency the most critical engineering aspect of these presses.

Embossing Machines

Embossing machines and processes add a raised or three-dimensional pattern to a substrate, usually paper. The resultant tactile effect can add a level of sophistication and personalization to any printed product.

Commonly used for high-end products like wedding invitations, business cards, and book covers, embossing can be used in combination with other printing presses, including digital and offset, to produce a print product that firmly stands out.

The unique feel and quality that embossing provides make it a technique particularly favored where a high degree of customization and distinction is necessary. Embossing machines are instrumental in packaging, labeling, and premium stationery where such an elegant touch is highly valued.

The depth and sharpness of an emboss are dictated by the precision of the die, the tonnage of the press, and the use of a proper counter-die. For a multi-level or sculpted emboss, the true artistry lies in a machine capable of maintaining perfect registration between the printed image and the die.

LED UV Printer

LED UV printers use ultraviolet lights to cure ink as it is printed. As the printer distributes ink on the surface of a material, specially designed UV lights follow close behind, curing or drying the ink instantly.

Thanks to their instant curing, LED UV printers are notable for their ability to print on a wide range of materials without the need for a special coating. This technology is highly applicable in the print industry for applications requiring fine detail and high-quality colors.

With LED UV printing, the colors are more vibrant, the prints are resistant to fading, and the process is more environmentally friendly than traditional printing techniques. This method is growing in popularity across the printing industry for products like signs and marketing materials.

The key advantage of LED UV curing is the low-heat ‘cold cure,’ which prevents heat-sensitive substrates like thin plastics from warping. Furthermore, the ability to ‘pin’ ink with a quick UV flash before the full cure allows for sharper details and better control over dot gain.

Large Format Printing Machine

Large format printing machines enable the printing of large-sized images and graphics without losing resolution or clarity. These are essential when producing banners, posters, wallpapers, murals, and more.

The applications for large format printers are extensive, often used in advertising, for trade show displays, and in architectural and decor settings. They have the capability to print on various materials, including canvas, vinyl, and other wide-range substrates.

With the capacity to handle unique and large scale print jobs, these printers support wide-ranging marketing efforts with materials that draw attention. The detail and durability that large format printing machines provide can make a significant impact in visual communication.

In large format printing, maintaining image sharpness across wide spans is a function of a highly rigid chassis and a precision media transport system. Any minute vibration or slippage in the material feed would be magnified in the final print, making structural stability a paramount design concern.

Strategic Selection: Aligning Printing Technology with Business Goals

Choosing the right printing technology is a critical investment that directly impacts your profitability and market position. An effective selection aligns the equipment’s core strengths with your specific business goals, moving beyond features to focus on performance and ROI.

Analyze Production Volume and Cost Model

Your production volume determines the most profitable cost model. Digital presses are the strategic choice for short runs (<1000 pieces) and on-demand jobs, as their absence of setup costs ensures profitability from the first print. For high-volume operations, Offset and Flexography offer an unbeatable low cost-per-piece by amortizing initial setup costs over long runs. Gravure is reserved for massive, industrial-scale production.

Master Substrate Compatibility

Substrate compatibility is paramount. Choose Offset for commercial paper and board applications; Flexography for flexible packaging and labels; Screen Printing or Dye Sublimation for apparel; and UV Printing for rigid, non-porous materials like plastic or metal

Define Your Quality Standard

The quality you deliver defines your market niche. Select Offset for the precise Pantone® color matching essential for brand integrity. For the unparalleled detail required in luxury markets, choose Gravure. For a unique, tactile finish, Letterpress offers an artisanal quality.

Evaluate Workflow and Speed

Evaluate your entire workflow, not just raw speed. Digital presses excel in ‘quick-change’ environments with near-zero job changeover times, ideal for handling multiple short-run jobs. In contrast, Offset and Flexo are engineered for maximum high-speed throughput in continuous, long-run production.

Leverage Customization

Finally, consider the need for personalization. If your projects require unique data on each piece (VDP), Digital is the only option. For standardized, identical prints, traditional methods like Offset provide a reliable and cost-effective path.

Ultimately, the right technology is a cornerstone of your production strategy, creating a powerful foundation for efficiency and sustainable growth.

The Future of Printing Press Technology

The Future of Printing Press Technology

The future of printing has shifted from forecast to reality, with today’s evolution defined by practical, integrated solutions. The industry’s trajectory is now driven by three core pillars: intelligent automation, production efficiency, and the commercial application of next-generation technologies.

AI-Driven Hyper-automation

The industry has advanced from simple automation to AI-driven hyper-automation, connecting the entire workflow from order intake to logistics. AI now autonomously manages job queues, performs real-time quality control with in-line vision systems, and enables predictive maintenance to maximize uptime and create a “smart factory” environment.

The Maturity of High-Speed Inkjet

High-speed production inkjet has matured into a mainstream powerhouse, now competing directly with offset in commercial and packaging sectors. Key breakthroughs include exceptional quality on standard coated stocks without primers and the availability of larger B2 and B1 formats. This combines the flexibility of digital with the production efficiency previously dominated by offset.

Sustainability as a Core Technical Metric

Sustainability is now a core technical metric, not just a buzzword. Mainstream practices include energy-efficient LED-UV curing, the widespread adoption of water-based inks to reduce VOC emissions, and smart makeready processes that drastically minimize paper and ink waste.

The Commercialization of Smart Packaging

Smart packaging has moved from concept to commercial reality as printable electronics are integrated into high-value products. The most prominent application is printed NFC/RFID antennas using conductive inks. Embedded in labels, these allow consumers to verify authenticity or launch interactive marketing experiences with a simple smartphone tap, fusing the physical product with digital technology.

Choose KETE GROUP LIMITED Printing Machines For Your Packaging and Printing Business

For businesses looking to stay at the forefront of the printing and packaging industry, selecting the right printing technology is paramount. KETE GROUP LIMITED printing machines stand out with years of experience in providing fine printing solutions for various materials and applications.

Why KETE GROUP LIMITED Stands Out in the Market

With a resource hub of information and current technologies, KETE GROUP LIMITED offers a diverse range of printing machines tailored to the unique needs of businesses and industries. From Flexographic printing machines to rotogravure printing machines and label printing machines, KETE GROUP LIMITED is committed to delivering quality, efficacy, and unparalleled customer service.

Wide Range of Machines

Automated Operating System

Quality Assurance

Advantages of Opting for KETE GROUP LIMITED Machinery

Whether the goal is to achieve unmatched print quality, accommodate different printing methods, or to secure equipment capable of handling large volumes and quick turnaround times, KETE GROUP LIMITED presents a robust solution for the modern market.

Food-Grade Printer

50% Efficiency Up

Free Spare Parts