Navigating the maze of printing technology can be a bit like trying to find a water-based ink pen in a stationery shop—overwhelming, yet oddly exciting. And when it comes to flexo printing vs offset printing, well, it’s even more baffling. Flexo? Offset? Rings about as clearly as a drying roller covered in wet ink. But hang on there–we’re here to demystify these printing processes and help you pick the right one for you!

Key takeaways:

| Difference | Flexo Printing | Offset Printing |

| Ink Type | Uses a wide variety of inks, including solvent-based, water-based, and UV inks. | Mostly relies on oil-based inks. |

| Plate Material | Uses flexible photopolymer printing plates. | Traditionally uses metal plates. |

| Substrate Versatility | Can print on a variety of flexible materials including plastic, foil, cardboard, and even non-porous materials. | Mainly prints on flat, porous surfaces such as paper and cardboard. |

| Setup Cost | Generally higher due to the cost of photopolymer plates and complex machine setup. | Lower in comparison; plate production and setup is simpler and cheaper. |

| Run Length | Ideal for longer run lengths due to fast printer setup and the durability of photopolymer plates. | Better suited for large volume print jobs due to cost efficiency with longer print runs, despite slower setup. |

| Speed | Faster print speed, especially for longer runs due to efficient plate change and quick machine adjustments. | Slower print speed, especially in large volume jobs, due to longer setup times. |

| Print Quality | Offers high-quality prints, with a slight edge on printing on various substrates. | Offers high-quality prints with exquisite detailing and deep, vibrant colors. |

| Maintenance | Fairly high maintenance required due to the cleaning of plates and replacement of inks. | Cleaning and maintenance are relatively easier. |

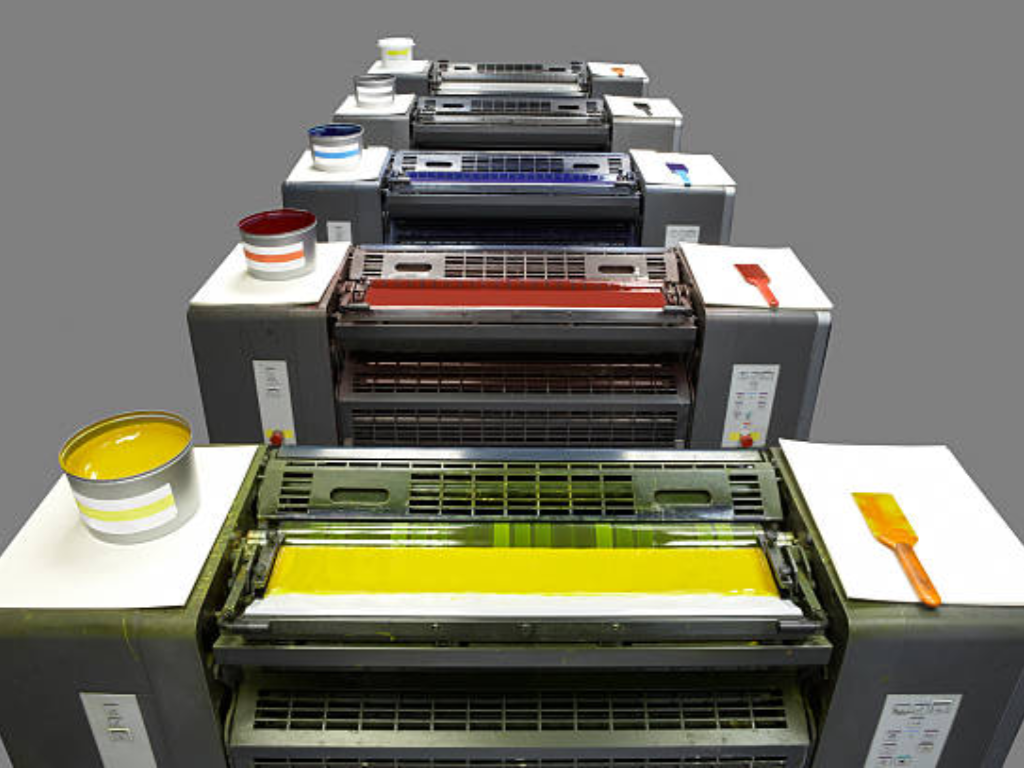

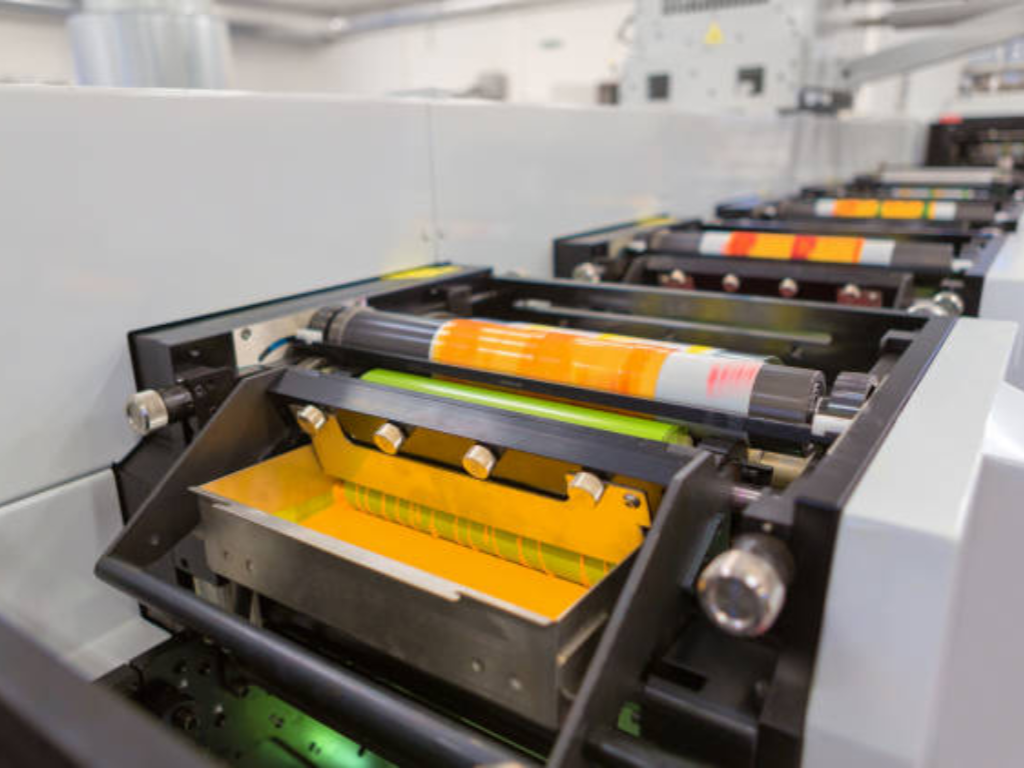

Understanding the Basics of Flexo Printing

Turn the spotlight on flexo printing—a high-speed, resilient printing method beloved by the packaging industry. The center of the flexo process is, you guessed it, the flexographic printing plate, flexo printing operates like a high-efficiency assembly line. Its rotary process is built for continuous, high-speed production, making it the workhorse of the high-volume packaging industry.. With flexo, you’re looking at machine setups that can handle any substrate, from cardboard to wrappers and even non-porous materials. Versatility with a capital V–that’s where the flexo magic thrives! You may like: flexo press guide.

Key Components of the Flexo Printing Process

Like any great act, the flexo process has a cast of key players. At center stage is the flexible relief plate, proud and durable. Sharing the spotlight is a series of rollers, each having its separate printing station. CMYK colors? No problem. This rotary process handles the coloring band admirably.

But that’s not all. The process also involves a photopolymer compound processed through a laser image setter – a high-tech colloquial for a piece of tech that’s about as cool as its name suggests. Flexo is a method that embraces digital technology, coming a long way from traditional techniques. Don’t let the technical jargon frighten you, though. Consider flexo printing like a high-powered car—it has a lot under the hood, but once you know how to drive it, wow, can it go places!

What Are The Advantages of Choosing Flexo Printing?

Here’s the deal: with flexo printing, you get a mix of durability, speed, and versatility that’s the equivalent of a superhero sprinter on roller skates. You’re looking at high-quality prints at a speed faster than gossip spreads. And the variety of materials you can print on ranges from flexible materials for retail bags to hardy cardboard for custom packages and brochures.

With flexo, you don’t get just fast turnaround times – you get a lethal combo of fast and high-quality. And did I mention its prowess when it comes to large volume print jobs? I’m not talking about “it’s a long way to the shop if you want a sausage roll” long; I mean “print enough wallpaper to cover a small city” long. Oh, and we’ve got solvent-based inks, water-based, even UV! Bet you’re falling in love with flexo already, huh?

Limitations of Flexo Printing: What to Consider?

But wait, before you rush to order that flexo printer near you, there’s something you need to know. Flexo isn’t all moonlight and roses. Like every process, it has its drawbacks. A key financial consideration for flexo printing is the significant initial setup cost, primarily due to the creation of the photopolymer plates. While this upfront investment is substantial, it is often offset by a lower per-unit cost on extremely long print runs.

The setup of a flexo printing machine also requires careful calibration, so you’ve gotta have a steady hand. And if your print job isn’t as long as a Star Wars marathon, flexo might be an overkill. Oh, and there’s cleaning – flexo machines love to play hard to get when it’s time for maintenance. Nothing a little diligence can’t fix, but something to consider when weighing between flexo vs offset printing.

Deep Dive into Offset Printing: Unraveling the Basics

Now, leaving the land of flexo printers, let’s dive into the realm of offset printing. Put simply, offset is like that reliable, easy-going friend we all have beloved by the print masses, especially for high-volume work on a flat surface. You know, the kind that doesn’t skip a beat when dealing with different printing techniques, from brochures to large-format lithography.

The heart of offset is the offset plate, a typically metal or polymer plate that’s about as robust and sturdy as a wall made of Lego bricks! This beauty handles the printing process, from ink to paper, like a well-rehearsed orchestra, each instrument playing its part to perfection.

Critical Steps in the Offset Printing Process

Here’s an inside scoop on the offset printing process: it’s a one-two-three dance between the image, ink, and substrate. First, your image gets etched onto the printing plate (step one). Then, ink rollers apply the ink to the etched areas (step two). Finally, an offset blanket transfers this ink onto your printing surface, anything from paper to cardboard to foil (step three).

Oh, and offset isn’t just a one-trick pony; it’s a meticulous multi-step process that includes prepress (your image setup), press (printing the run), and post-press (drying, cutting, and finishing). So next time someone asks, “What is an offset printer?”, you can tell ’em it’s like a printing orchestra – with a prelude, symphony, and grand finale!

Exploring the Strengths of Offset Printing

Let’s clink glasses to the strengths of offset printing! By using an offset press, you can print to your heart’s content, delivering high-quality prints faster than you can say “lithography.” It’s that friend who has come to the party prepared, ready to churn out wholesale amounts of brochures or offer a helping hand with large-scale litho printing gigs.

The good news doesn’t stop there. Our friend, the offset printing machine, handles a variety of substrates and delivers outstanding print quality, vibrant colors, and details so fine, they’d make an art dealer swoon. Oh, and did we mention the cost-effectiveness for large print runs? How’s that for an offset benefit that touches your prints and your wallet?

Potential Challenges of Offset Printing

Alright then, the time has come to pull back the curtain and reveal the less glossy side of the offset printing processes. These challenges aren’t quite the nightmare that keeps printers awake at night, but they’re worth knowing. For instance, our dear friend offset can be somewhat slow to start. The setup and plate production time means your print job might be delayed–talk about a late start to the show!

Moreover, offset printing requires higher minimum print volumes to be cost-effective. So, if you have a short print run, you may feel like you’ve hiked a mountain only to find a molehill! Plus, making changes mid-run can be as challenging as changing lanes in rush hour traffic.

Comparing the Printing Plates in Flexo and Offset

Ready to peep into how the printing plates differ in flexo vs offset printing? Well, strap in! Flexo employs photopolymer plates, while offset typically uses metal plates. Imagine the difference between a sturdy, flexible yoga master and a heavy lifting weight trainer–that’s practically the difference between the fast, flexible flexo printing plates and robust, durable offset printing ones.

The plates used in flexo can handle a wider range of inks and surfaces, while offset plates demand a flat surface for proper ink transfer. To put it simply, one’s a jack-of-all-trades, while the other’s a master of one.

Ink Types Used in Flexo and Offset Printing: A Comparison

You might say, “Ink is ink, what’s the fuss about?” Well, let me tell you – it’s a whole new world when you go down the printing rabbit hole. In the two main contenders, namely flexo vs offset printing, we are dealing with quite a different artillery.

flexo printing wears the versatility crown, using a broader range of inks like solvent-based inks, UV and, not to forget, our beloved water-based. It’s like having a selection box of cupcakes – so many flavors to enjoy…I mean, inks to print with!

On the flip side, offset printing typically relies on oil-based inks, frequently used to charge at large print runs. It’s like ordering platter upon platter of delicious nuggets (offset prints) using only one secret sauce (oil-based ink). Interesting comparison, huh?

Assessing the Material Suitability for Flexo vs Offset Printing

How about a quick sprint down substrate lane? In the flexo vs offset war of the press, substrates play a pretty big role. The term ‘substrate’ refers to the surface or material being printed on. The choice of substrate is a critical factor, as flexo excels on a wide variety of materials, including non-porous surfaces, while offset is primarily suited for paper and board and even retail bags.

On the other hand, our good buddy offset is a bit of an old-school player. Preferring a flat surface, it works wonders with paper and cardboard. So, are you looking for versatility or specialization? That’s the million-dollar question when considering flexo vs offset.

Sustainability in Printing: A Technical Comparison

Evaluating the environmental impact of printing is critical. Flexography and offset printing offer distinct sustainability profiles based on three key areas.

First, flexography excels with low-impact inks. Its widespread use of water-based and UV-cured inks minimizes Volatile Organic Compound (VOC) emissions, a significant advantage for sensitive applications like food packaging when compared to traditional solvent-based offset inks.

Second, offset holds a clear advantage in material circularity. Its aluminum printing plates are highly and easily recyclable. In contrast, flexographic photopolymer plates, while improving, currently represent a more complex waste stream.

Finally, regarding operational waste, the offset makeready process can consume more substrate to achieve stable color. Modern flexo presses often feature streamlined setups that reduce initial material consumption on high-volume jobs.

Ultimately, the choice requires a balanced assessment of priorities: flexography’s lower-emission inks versus offset’s superior plate recyclability and the specific waste profile of the application.

Costs and Affordability: Flexo Printing vs Offset Printing Face-off

Money, money, money, must be funny…unless you’re talking about printing costs! In our financial showdown between flexo and offset, you might find it’s not quite as black-and-white as the old ABBA song.

On the face of it, flexo seems pricy with its high initial setup cost. But if you need high-volume print jobs, it can cost less per unit than offset. Moreover, the variety of inks and materials in the flexo arena makes cost comparison dependent on the specific job.

Meanwhile, offset comes with an ace up its sleeve: affordability for long print runs. But, it isn’t the economical choice for small-scale gigs. For instance, for a 5,000-unit run, an offset setup of $400 is much cheaper than a flexo setup of $1,500. However, for a 500,000-unit run, the total cost for flexo becomes far more economical because its high setup fee is outweighed by an extremely low per-unit printing cost. Choosing between the two, offset vs flexo printing, is akin to jumping from thinking about daily coffee expenses to contemplating the lease on a new car. All hang on to your specific needs, really.

Flexo and Offset: Examining Performance on Different Print Runs

Ever wondered how the big guns of printing, flexo, and offset, perform on different print run scenarios? It’s kind of like comparing sprinters to marathon runners–each has its shining moments. Flexo’s superpower is its capability to produce high-quality prints at a rapid pace, making it ideal for extensive print runs. The more printing, the merrier the flexo.

However, offset printing, like that steadfast friend who’s always there, excels primarily in high-volume jobs–the ones that could fill an Olympic-sized pool with printed material. But remember, the prep time for offset printing is worth considering, as a quick-fire job may not be its forte.

Conclusive Remarks: Making the Right Choice between Flexo and Offset Printing

Choosing the perfect printing press might seem as baffling as knowing the difference between different blends of coffee beans–dark roast, light roast, medium roast, heck, just give me the caffeine! The flexography vs lithography, or for us lay folks, flexo vs offset debate, is much the same.

Flexo printing, with its immense versatility and ability for rapid, large-scale print jobs, could be your best bet if you wish to print on diverse materials at high speeds. On the other hand, Offset printing, versatile in its own right, and adored for the exquisite and consistent quality it offers, could be your staunch ally for large-scale print jobs mainly on flat surfaces like paper or cardboard.

Choosing between flexo vs litho, or digital vs offset printing, is not about picking the superior method. Instead, it’s about selecting what suits your specific printing needs the best. So, whip out your list of printing needs and get to know these methods a little better – your perfect printing partner awaits!

The key to success lies in converting your equipment’s capabilities into customer value. As a professional press manufacturer, KETE provides more than just high-performance machinery; we strive to be your technical backbone. When your clients present complex or innovative printing demands, leverage our expertise. We can assist in analyzing designs and recommend optimal machine parameters and processing advice, helping you transform challenging jobs into high-margin orders and solidify your status as an expert in your customers’ eyes. Ready to turn challenges into opportunities? Contact our team for a technical consultation today. Ready to turn challenges into opportunities? Contact our team for a technical consultation today.

In conclusion, selecting the right printing method is a critical business decision. By systematically evaluating your project’s specific needs against the capabilities of flexo and offset, you can make an informed choice that optimizes both quality and budget.

And remember, we’re barely scratching the surface. Print technology is broader than the grin on an accomplished printer’s face! So, keep digging, keep exploring, and most importantly, keep printing!