Introduction to Label Printing

Today, labels have become critical elements of branding, information transfer, and regulatory measures in the rapidly growing markets. Across industries, in the consumer goods sector as well as in the industrial sector, there is a rising need for better quality labels. Industry research indicates that the label printing industry will reach over $50 billion by 2028 due to factors such as individualization of packaging, use of sustainable materials, and increased stricter traceability regulations.

Flexo Printing

Flexo printing is one of the most flexible printing techniques that are commonly used in the label and packaging sectors. It uses bladed plates of rubber or photopolymer that are rolled on a cylinder to apply ink on different surfaces. Such surfaces can be paper, plastic, metal foils, and even corrugated cardboard. It uses a sequence of rollers that deposit ink uniformly, ensuring fast and consistent results across large print runs.

The advantage of flexo printing is the ability to produce large quantities of prints in a short time. It excels in producing a high number of labels with uniformity in quality, which is suitable for the food, beverage, and consumer goods sectors. It has also been enhanced by recent technological developments to deliver high-quality details and bright colors and even handle variable data for serialized or custom labels.

Nonetheless, flexographic printing is a little more expensive and time-consuming because it uses plates that are made to order for each design. This makes flexographic printing more appropriate for projects that require large quantities of prints, where the cost per print is greatly reduced and the initial costs of the equipment justified. If you are looking for a fast, efficient, and accurate method of printing for large runs, flexo printing is a cost-effective and professional method.

Gravure Printing

Gravure printing is a high-precision printing technique which is well known for its capability to print fine images and fine-line designs. In this process, the design is cut or carved into a metal cylinder. In the process of printing, the cylinder is dipped in an ink reservoir and the surplus ink is removed by a doctor’s blade. The ink that remains in the engraved cells is then directly transferred onto the material which gives the print a very high level of clarity and bright colors.

The major advantage of gravure printing is the ability to achieve high-quality print, which is suitable for premium products such as luxury product labels, packaging, and magazines. However, the process is costly at the initial stage because the cylinders have to be engraved to suit the specific product. This makes gravure printing more appropriate for high-volume production since the costs can be spread out over the number of units produced. For industries that need high quality and durability packaging such as the cosmetic or the beverage industries, gravure printing is ideal.

Screen Printing

Screen printing is a flexible printing technique that involves using a mesh screen stencil to apply ink on a surface. In the process, ink is forced through the mesh with a squeegee so that it can stick to such surfaces as plastic, glass, fabric, or metal. This method is especially useful for printing on curved or irregular-shaped items like bottles, jars, or promotional items.

The major benefit of screen printing is that it offers bright and long-lasting prints that do not fade, wear, or get damaged by harsh weather conditions. If you are using specific materials or require labels made from a wide variety of materials with a rough or embossed look or with a glossy finish, then screen printing is the best option. But it is a slower process than other methods and therefore ideal for small to medium runs or specialized designs where quality and uniqueness are priorities.

Digital Printing

Digital printing is one of the most flexible and highly versatile label printing methods that directly transfer digital files to the printing surface without the need for creating printing plates, allowing businesses to print directly from digital files. It includes the use of high-technology inkjet or laser technologies that spray ink or toner on the material. This cuts down on the amount of time required to set up the equipment and also cuts down on cost making digital printing suitable for short runs, on-demand, and personalized orders.

Its benefits include its flexibility to accommodate variable data like the bar code number, QR code, or serial number and the high-resolution image quality with accurate color density. However, it’s less cost-effective in large-scale production when compared to conventional techniques.

Digital printing is ideal for industries that need short runs, customization, and quick turnaround time such as product labels, promotional packaging, or seasonal products.

Offset Printing

Offset printing is one of the oldest and most effective techniques that can be used for the production of high-quality labels. This is a process of using a metal plate to transfer ink to a rubber blanket and then applying the ink on the printing surface. This indirect method provides accurate and uniform results, which is suitable for complex patterns and fine prints.

Offset printing could produce very clear and bright colors and maintain the same quality even with large amounts of prints. It can accommodate paper, plastic, and metallic finishes hence it can be used in a number of applications. However, similar to flexo printing, the process involves the need to produce custom plates, which increases the initial costs and time of setting up the process, making it less ideal for short-run or small-scale projects.

Offset printing is ideal for large-scale projects where the need to save money, and produce accurate and consistent prints is of the essence.

UV Printing

UV printing is an advanced printing technique that applies liquid ink on a surface and exposes that to ultraviolet light. The ink cures instantly on being exposed to UV light. As a result, this method is capable of being used on unconventional materials such as metals and plastics amongst others. This is achievable due to UV printing’s unique solid curing method.

One of the key benefits of UV printing is the exceptional quality of prints produced alongside the finer details staying sharp and vivid, compared to other printing methods. Labels created with UV printing are suitable for industries such as cosmetics and beverages, due to their long-lasting endurance alongside high-impact purpose. However, the process can be costlier than traditional methods, making it better suited for applications where quality and durability are critical.

Thermal Transfer Printing

Thermal transfer printing is one of the most common techniques that employ heat to transfer ink from a ribbon onto the label material. It entails the printhead heating the ribbon and transferring the ink to the surface through melting and fusing it into the surface. This results in long-lasting, high-quality prints that are not easily wiped off, faded, or affected by other adverse weather conditions.

It is capable of creating durable labels and can accommodate variable information such as barcodes, serial numbers, and shipping details. And especially suitable for industries that need labels that can be resistant to high temperatures, moisture, and chemicals. Although the method uses ribbons, which are costly and increase operational costs, and is slower than other printing methods, it is not suitable for large production, but due to its low maintenance and high reliability, it is suitable for industrial and logistical uses.

Laser Marking

Laser marking is a state-of-the-art printing technology that employs laser beams to produce permanent marks on label substrates. The process involves focusing a high-power laser on the surface of the material to either carve, mark, or change the color of the material to create the design. Laser marking is different from other techniques such as ink or ribbon where the material is changed and the final product is permanent and highly accurate.

This method is particularly useful for applications where labels are expected to be exposed to harsh conditions such as heat, moisture, abrasion, or chemicals. It is commonly used for printing important information such as serial numbers, QR codes, and barcodes in the automotive, electronics, and pharmaceutical industries.

Some of the benefits include accuracy, reliability, and the fact that it does not use consumables such as ink or ribbons, thus cutting costs in the long run. Despite the fact that the initial cost of a laser printer may be high, the printer is long-lasting and very accurate and therefore may be suitable for organizations with specific needs.

Letterpress Printing

Letterpress printing is one of the oldest printing techniques that work by having ink being transferred from the raised surfaces of the printing plate onto the label material. The process is of placing the material against an inked plate with a raised design or text and then applying pressure to transfer the ink onto the surface and get a clear and sharp image. This method can also create an embossed effect, which gives the design a raised surface and a three-dimensional feel.

Known for its craftsmanship, letterpress printing excels in creating high-quality, unique labels, often used by luxury brands and artisanal products. But it is not suitable for mass production because it takes more time and has higher costs of setting up. This technique is suitable for companies that want to create an association with tradition, authenticity, and rarity in their packaging.

Hot Stamping

Hot stamping is a specific type of printing that uses a heated metal die with the design to be printed on the foil and then transferred to the label surface. The heat and pressure applied ensure that the foil sticks well on the surface and the final result is a shiny, long-lasting, and professional look.

This method is highly appreciated for the opportunities to produce bright, luxurious labels that can improve the appearance of products. It is widely applied in the wine, cosmetics, and luxury packaging industries. Although the process is more costly because of the need to have special dies and foils, the process offers excellent graphic appeal and can be used to improve the brand image of the product, particularly for premium brands.

Comparing Different Label Print Technologies: Making the Right Choice

Choosing an appropriate option when it comes to label printing technology is crucial for almost any business that wishes to create high-quality labels quickly and easily. It is determined by a number of vital considerations: cost, quantity, type of material used in the label, and quality. To aid you in better decision-making, the table below might be of assistance:

| Printing Technology | Unit Cost (Small Batch, 1,000 Units) | Unit Cost (High Volume, 100,000 Units) | Quantity | Label Material Type | Quality |

| Flexographic Printing | $0.10–$0.15 | $0.03 | High-volume production | Flexible materials (e.g., plastic, foil) | High color quality, fine details |

| Gravure Printing | $0.15–$0.20 | Not applicable | High durability, premium products | Flexible packaging (e.g., foil, plastic) | Exceptional clarity, vibrant colors |

| Screen Printing | $0.50–$0.70 | Not suitable for large runs | Small-medium runs, unique designs | Various (e.g., glass, textiles, plastics) | Bright, durable prints |

| Digital Printing | $0.25–$0.35 | $0.10–$0.15 | Short runs, customization | Variety of materials (e.g., paper, plastic) | High-resolution, supports variable data |

| Offset Printing | $0.05–$0.08 | $0.03–$0.05 | Large runs | Paper, cardboard | High color fidelity, detailed designs |

| UV Printing | $0.30–$0.40 | Not applicable | High-quality, long-lasting labels | Unconventional materials like glass and metals | Sharp, vibrant colors, long-lasting |

| Thermal Transfer Printing | $0.20–$0.30 | Not suitable for large runs | Industrial/logistics labels | Paper, synthetic materials | Durable, resistant to harsh conditions |

| Laser Marking | $0.15–$0.25 | Not suitable for large runs | Small runs, precision work | Metal, plastic, glass | Permanent, precise markings |

| Letterpress Printing | $0.50–$0.70 | Not applicable | Luxury or artisanal labels | Paper, specialty materials | High-quality, embossed effect |

| Hot Stamping | $1.00–$1.50 | Not applicable | Luxury packaging, premium brands | Paper, foil, plastic (for metallic effects) | Shiny, metallic, or glossy finishes |

Note: The exact cost may differ depending on the manufacturer, type of material used, design, and other specifications. When making the final decision, it is recommended to refer to data and quotes from specific suppliers or manufacturers. For a more precise price, you can get a quote here for free.

How to Choose the Right Label Printing Machine?

Choosing the best label printing machine is vital for optimizing cost, quality, and efficiency. Here are the key factors to consider :

Printing Width

One of the important criteria when choosing a printing machine is the label width. Printers can be of various widths, normally ranging from 2 inches to 13 inches. For labels that are used in packaging or on products with large dimensions, wider printers with a range of 8-13 inches are needed for the printing. On the other hand, for small labels that are used for barcodes or product tags, it is more appropriate to use machines with a narrow width of 2-4 inches. The width of the printer should also correspond to the size of the labels that you require so that the printer can print consistent, high-quality labels to the best of its capacity without having to waste a lot of time or material.

Stability and Reliability

When choosing the label printer, it is crucial to focus on its stability and reliability to avoid frequent breakdowns and poor quality of the labels. For instance, Flexographic printers are very robust and are built to be used in environments where they are used for a long time in a day. They can run for thousands of hours with proper maintenance but need to be checked frequently on rollers, plates, and ink systems to avoid defects. On the other hand, digital printers are more reliable with fewer mechanical parts hence less likely to break down, especially in short runs. Evaluate the printer’s error rate, endurance to work for long hours, and the frequency of replacement parts to ensure it carries on smoothly and without interruptions in the future.

Automation and Ease of Use

For corporations that require precision labeling or even have complex labeling tasks with huge volumes, automation can improve productivity to a significant level. The incorporation of auto registration and label alignment features reduces the need for manual adjustments, which helps minimize errors. Issues that arise during the process are instantly recognized by the sensor technology that monitors the entire operation in real time, guaranteeing print quality. For smaller operations, a simpler, user-friendly interface might suffice, which means spending a minimal amount of time training employees resulting in fewer mistakes while operators focus more on quality control. These machines that have simple software interfaces, automatic controls, and easy-to-switch components still preserve productivity while time-saving which makes it most suitable for companies that have simple or infrequent activity for labeling.

Maintenance and Support

Last but not least, it is crucial to have reliable maintenance and good technical support to ensure that a printer is always in good working condition. The upkeep demands of machines generally differ with their level of complexity. For example, laser printers as machines with fewer moving parts, have low upkeep demands. However, some complicated systems might necessitate specialized care. Selecting a manufacturer who can provide good after-sales service such as warranties, training, and timely repairs is important to reduce downtime. Make sure that the service and parts support are adequate to meet your business requirements.

With meticulous consideration of these elements, you can choose the most suitable label printing machine for his or her enterprise.

Conclusion

The label printing industry is a huge one and offers solutions for every business need across various industries. Be it classic letterpress printing or new technologies such as UV printing and digital label printing, each has its own respective advantages within the printing process. By recognizing types of label printing, businesses are allowed to choose the correct one for them, be it mass production, unique original designs, or labels that require being extremely robust.

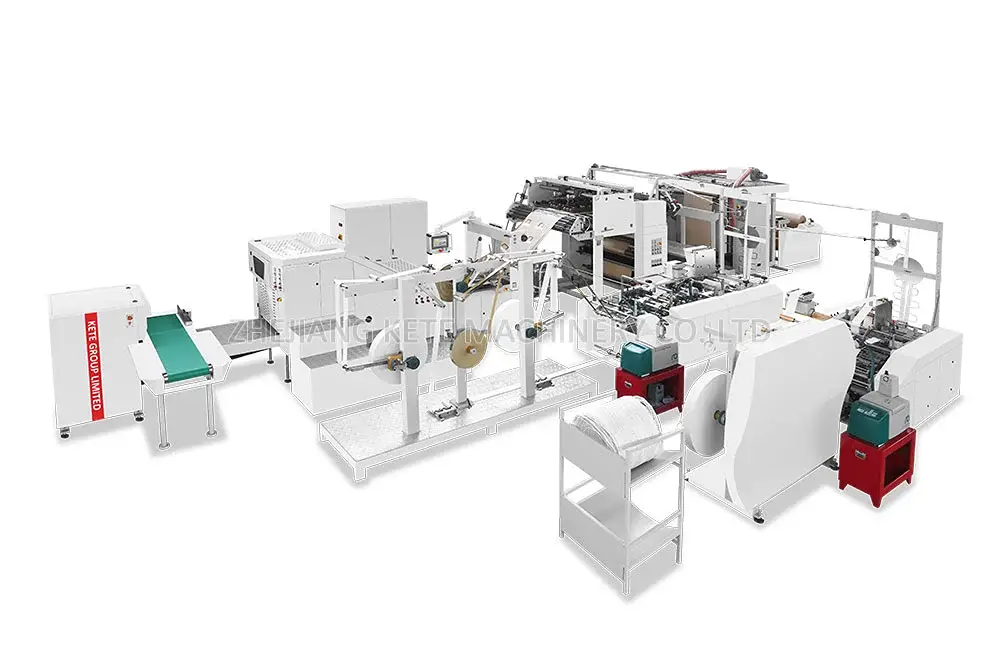

Explore KETE Label Printing Machines

As China’s leading label printing machine manufacturer, KETE specializes in providing customized label printing solutions. Our machines are flexible to your production requirements, in terms of the production rate, size of the material, and the complexity of the process. Whether you require fast production, flexible material management, or accurate color reproduction, our machines are designed to fit your business.

KETE Label Printing Machines have a speed of up to 180 meters per minute making it ideal for large production lines. The print widths are adjustable from 320 to 550mm and the printers can handle 2-6 color printing, thus making it possible to print different label types and on different materials. Each machine is tested before it is shipped out to the customer to ensure that it will not have problems at all when used for the first time.

KETE offers you a one-year warranty and technical support so that your production is efficient and without interruptions. Allow us to help you enhance your label production with the best technology and reliable service.

FAQS

Q: Which printing method is the most durable and waterproof?

Best Method: Thermal Transfer printing using a Resin Ribbon. It offers maximum resistance to extreme temperatures, chemicals, and outdoor UV exposure.

Best Material: The label stock is crucial.

Paper: Not durable; absorbs water and tears easily.

Synthetics (BOPP/PET): Plastic-based materials that are inherently waterproof, oil-proof, and tear-resistant.

Q: What are the main categories of label printers?

Desktop Printers: Compact units designed for office use, shipping labels, and low-volume printing.

Industrial Printers: Rugged, high-speed machines built for warehouses, manufacturing, and 24/7 high-volume output.

Mobile Printers: Portable, battery-operated devices for logistics, field service, and on-the-go printing.

Digital Label Presses: Professional systems for mass-producing high-quality, full-color product packaging.

RFID Printers: Specialized units that print and encode RFID tags simultaneously for asset tracking and supply chain management.