Introduction

The choice of right industrial machinery is one of the key factors that define the efficiency, quality, and profitability of many manufacturing industries. One of the most important pieces of equipment that require investment is the slitting rewinding machine especially in the converting industries. These units serve the purpose of reducing the width of large master rolls of material for further processing or for direct end use.

The decision making process of acquiring such a machine is not a simple one and it involves the consideration of the type of material to be used, the production capacity, the technological differences and the cost. A wrong decision can result in production delays, material losses, low quality products, and hence, reduced competitiveness.

This paper aims to give a clear understanding of slitting rewinding machines, their working, different types, uses, and the various factors that should be considered when choosing a machine that will be most suitable for a certain operation to assist the decision makers in this area to make the right decision in their acquisition.

What is a Slitting Rewinding Machine?

A slitter rewinder machine is an efficient system that is used to cut wide parent rolls into narrow ones and rewind them on cores at the same time. The machine also cuts the material into the required length and rewinds the new sections on cores that are ready for use or for distribution. This machine functions as an industrial material tailor that executes precise subdivisions and reconfiguration of slitter rewinder machines for their actual intended uses.

The Working Principle Behind Efficient Slitting and Rewinding

A brief description of the slitting rewinding machine’s functions reveals how it works. It entails the passing of a web of material through several controlled steps from the master roll to the finished rolls. Here is a brief description of the main parts and the process of using it:

| Component | Function Description |

| Unwinding Unit | Holds the large master roll and feeds the material web smoothly into the machine path. Includes braking or drive systems for controlled payout. |

| Tension Control System | Maintains consistent web tension to prevent defects like stretching, wrinkling, or slackness. Often features automatic tension adjustment. |

| Slitting Unit | Uses precisely positioned knives (shear, razor, or crush cutting) to make longitudinal cuts and divide the material into narrower strips with accurate dimensions. |

| Guiding Rollers | Ensure straight and smooth material travels along the path; specialized rollers like spreader rolls remove wrinkles. |

| Rewinding Section | Winds the slit strips onto new cores, controlling winding tension, speed, and roll build-up to ensure uniform, high-quality finished rolls. |

In other words, the machine effectively controls the material flow – feeding it under tension, cutting it, guiding the strands and winding them into high quality finished rolls for further use. The techniques of slitting and rewinding depend on the type of material and the intended use of the product.

Exploring Different Types of Slitting Rewinding Machines for Your Needs

The slitting rewinder market is vast and varied, which is due to the broad range of materials that is being processed and the nature of the application. It is important to understand the main categories based on the slitting method, the winding method, and the configuration of the machine in order to choose the right one. The following delves into these common types.

By Slitting Methods

The type of slitting depends on the material being cut and the quality of the edge required.

Shear Slitting Machine

Shear slitting uses two rotating circular knives: a dish-shaped knife that is on top of the web and a flat knife that is at the bottom of the web, which works in a scissor-like manner. The material then goes through the nip point where it is cut cleanly.

- Best for: paper, paperboard, thicker films, foils, laminates, nonwovens, fabrics.

- Pros: creates very smooth and burr-free edges; creates very little dust; works well on various materials and thicknesses; blades can be sharpened again in many cases.

- Cons: More difficult to set up than razor slitting; top and bottom knives need to be aligned; higher initial cost of tools.

Razor Slitting Machine

This method employs the use of simple sharp razor blades. The blades can be placed to slit the web “in the air” (razor-in-air) between two rollers or against a grooved roller (razor-in-groove or wrap slitting).

- Best for: Light gauge films (PET, BOPP, PE), light foils, very thin laminates.

- Pros: low cost of tooling; easy to install; suitable for high speed cutting on the right material.

- Cons: Blades become dull rather fast and are generally not re-sharpenable; not suitable for thick, rigid or abrasive substrates; may cause heat build-up or stretching of the film; edge beads or slight warping of the material may occur in some cases.

Crush Slitting Machine (Score Cut Slitting)

Crush cutting involves pressing a blunt-edged (or slightly radiused) circular knife against the material, which is supported by a hardened steel anvil roll. The pressure forces the material to fracture or “crush” along the desired line.

- Best for: Pressure-sensitive adhesives (PSA), tapes, label stock, textiles, nonwovens, foam, rubber, multi-layer materials where adhesives might gum up shear knives.

- Pros: Effective for materials with sticky adhesives; relatively simple setup.

- Cons: Can generate edge dust or fibers; edge quality might not be as clean or precise as shear slitting; anvil roll requires periodic regrinding; potential for edge deformation (work hardening in metals).

By Winding Method

The winding method defines how tension is applied and how the finished rolls are constructed.

Center Winding Slitters

In center winding, the rewind shafts are driven directly and apply the torque on the core on which the material is wound. Tension is maintained by adjusting the amount of torque that is applied on these shafts.

- Best for: Materials requiring precise control of tension during winding (thin films, foils, some nonwovens); processes where tension must be controlled during the roll build-up; smaller diameters finished rolls.

- Pros: Precise tension control, particularly when using differential rewind shafts that enable each slit roll to rewind at the right tension; does not apply surface pressure to the material, thereby improving the quality of the wound material surface.

- Cons: The maximum roll diameter is defined by the torque of the drives and the stability of the winding shaft; the maximum roll diameter is determined by the winding speed may be lower when compared to surface winders for large diameter rolls.

Surface Winding Slitters

Surface winding incorporates driven drums or rollers that contact the outer surface of the winding rolls. The winding force is provided via the friction that exists between the driven drum and the material surface. The rewind shafts, which offer structural support, need not be driven.

- Best for: Non-sensitive materials that can tolerate surface pressure including paper, paperboard, robust films, textiles, large diameter finished rolls, and those needing high-speed operation.

- Pros: It can reach high speeds and produce very large and heavy rolls; tension control is easier; not as sensitive to core changes.

- Cons: Not ideal for materials that are easily marred by the pressure of the roller; tension may not be as easily controlled, particularly with materials of different thickness; may trap air, which results in softer rolls if not dealt with appropriately.

Center-Surface Winding Slitters

These machines combine elements of both methods. They typically use driven rewind shafts (center wind), assisted by contact with a driven drum (surface wind). This allows for precise tension control while also supporting the roll and enabling higher speeds and larger diameters.

- Best for: A wide range of materials and applications requiring versatility; large diameter rolls needing precise tension control; managing difficult-to-wind materials.

- Pros: Offers the advantages of both methods – good tension control and ability to wind large, dense rolls; highly versatile.

- Cons: More complex and generally more expensive than pure center or surface winders.

By Number of Winding Shafts

The configuration of the rewind section impacts productivity and tension control capabilities.

Single Rewind Shaft Slitter

The easiest layout where all slit strands are placed onto cores which are mounted on a single rewind shaft.

- Best for: Applications where small changes in tension across the web are acceptable; web materials with small thickness variations; and low cost.

- Pros: Simple design; lower initial cost.

- Cons: It is challenging to maintain a consistent tension throughout all the slit rolls especially if the parent roll has a different caliper; there are restrictions on the number of slits or minimum width of the slit.

Duplex Slitter Rewinder

Features two rewind shafts. Typically, the slit strands are wound alternately onto the upper and lower (or front and back) shafts. This capability permits adjacent rolls to be wound independently.

- Best for: General purpose slitting; situations where there is a need to have better tension control between the rolls; materials that have varying thickness.

- Pros: Better control of tension than single shaft; more versatility in terms of slit width and number of rolls; the most used configuration because of its versatility.

- Cons: More complex and costly than single shaft machines.

Turret Slitter Rewinder

It is equipped with two or more rewind shafts which are mounted on a rotating turret structure. One set of shafts can be winding while the other set is being unloaded (finished rolls are taken off and new cores put on). When the winding is complete to the required diameter, the turret turns to bring the new cored shafts into the winding position and the completed set into the unloading position, enabling almost continuous operation.

- Best for: Large scale production processes where it is desirable to have minimal time between sets (e.g., tape, label stock, commodity films).

- Pros: Reduces the time required for roll changes to a large extent, thus increasing production; suitable for high speed and continuous production.

- Cons: Most complex and expensive configuration; needs more floor area; generally used for specific, intensive operations.

Advantages of Investing in a Slitting Rewinding Machine

The incorporation of an appropriate slitting rewinding machine in a production line has numerous advantages in terms of operations and costs:

Higher Production Rates: Today’s slitters are built for speed and are mostly operated automatically. In comparison to manual cutting or outsourcing, an in-house slitter enhances the rate at which master rolls are converted into convenient formats. This is because features such as fast job change, knife positioning, and high operating speed are all factors that lead to increased production.

Improved Product Quality: Accurate slitting provides better width tolerance and edge trim, which is vital for many uses. High tension control systems ensure that the rolls are wound uniformly with the right density and profile to avoid defects and to enhance the performance in the subsequent processes. This consistency leads to a better end product being produced in the market.

Less Material Waste: Accurate slitting also reduces the amount of edge trim waste. In addition, the possibility of cutting usable parts from flawed master rolls or reprocessing the remaining rolls also helps to minimize material wastage, which is particularly costly when the material is expensive.

Reduced Operating Expenses: Although it is an initial capital investment, a slitter rewinder eliminates the need to outsource converting services, which come with additional costs such as transportation. Automation also leads to a decrease in the number of workers needed to produce a given level of output. This also directly reduces the amount of material that is used, hence cutting the overall cost of the material.

Better Control: In-house slitting means that companies can better control the quality of the slit products and the process of slitting itself. It also allows for the production of specific widths and roll sizes as and when required, thus minimizing the need for pre-slit material stock.

Optimized Inventory Management: It is possible to buy materials in large rolls that are cost effective and then slit to the required size. This helps to reduce the raw material inventory and also gives better control over the finished rolls that can be produced or marketed.

Purchasing the right slitting rewinding machine is a wise investment in the control of operations, quality, and cost.

Key Factors to Consider When Buying a Slitting Rewinder

Selecting the most appropriate slitting rewinder requires careful consideration of several interconnected factors related to your materials, processes, and business objectives:

Material Properties:

- What types of materials will be processed (film, paper, foil, laminate, nonwoven, etc.)?

- What is the range of material thickness (gauge/caliper)?

- Is the material sensitive to tension, surface pressure, scratching, or heat?

- Does it contain adhesives or coatings? Is it abrasive?

Slitting Specifications:

- What are the minimum and maximum values of the slit width?

- What is the allowable error (precision) for the width of the slits?

- What is the required edge quality (clean shear, acceptable crush)?

Roll Dimensions:

- What is the maximum diameter and width of the master rolls? What is their weight?

- What should be the minimum and maximum diameters of the finished rolls? Maximum weight?

- What are the standard dimensions of the unwind and rewind cores, namely the inner diameter, outer diameter and the material used?

Production Requirements:

- What is the required production speed in meters or feet per minute?

- What is the expected throughput or volume in terms of the number of rolls per shift/day?

- Is it important to have a system that operates as much as possible without interruptions? (Suggests Turret)

Slitting and Winding Technology:

- Which of the slitting method is better between Shear, Razor and Crush based on material and edge quality?

- Which of the winding method is suitable (Center, Surface, Center-Surface) based on material sensitivity, roll size, and tension requirement?

- Which rewind shaft configuration is most appropriate for tension control and productivity (Single, Duplex, Turret)? Does differential winding capability add value?

Automation and Features:

- What degree of automation is required (e.g., knife positioning, tension control, core loading/unloading, roll removal aid)?

- Is it necessary to have web guiding systems, inspection systems or trim removal systems?

Operational Considerations:

- What safety features are essential?

- How crucial is it to have the device easy to set up, use, and maintain?

- What is the amount of floor area and height of the ceiling?

- What are the power and compressed air demands?

Budget and ROI:

- What is the amount of money that is available for the initial investment?

- What is the expected ROI in terms of productivity, time and cost savings, and quality?

Manufacturer Support:

- What is the reputation of the manufacturer?

- What technical support, service, spare parts, and training are provided?

Considering these aspects will help you to choose a machine that will be useful for the present and will serve you well in the future.

Diverse Applications of Slitting Rewinding Machines Across Industries

Slitting rewinding machines are used in a wide range of industries:

Flexible Packaging: Cutting printed or laminated films such as BOPP, PET, PE, CPP into desired widths for FFS machines, bag making machines or pouch converters.

Label Stock Manufacturing: The process of cutting wide rolls of pressure-sensitive adhesive laminates (face stock, adhesive, liner) into narrower rolls suitable for label printing presses.

Tape Manufacturing: Cutting of adhesive tapes such as packaging tapes, masking tapes, double sided tapes, electrical tapes and other tapes to standard and specific sizes.

Paper Mills and Converting: Cutting wide mill rolls of paper and paperboard into smaller rolls for printing presses, corrugated box manufacturing, paper bag production, and other paper products.

Film Manufacturing: The process of cutting of films that have been extruded or cast into narrower widths of intermediate or finished products.

Nonwovens: Cutting rolls of nonwoven fabrics used in baby diapers, wipes, medical gowns and masks, filters and industrial applications.

Textiles and Technical Textiles: Slitting fabrics for apparel, home furnishings, automotive interiors, and specialized industrial applications.

Foils: Aluminum and other metal foils for use in packaging, insulation and other industrial applications.

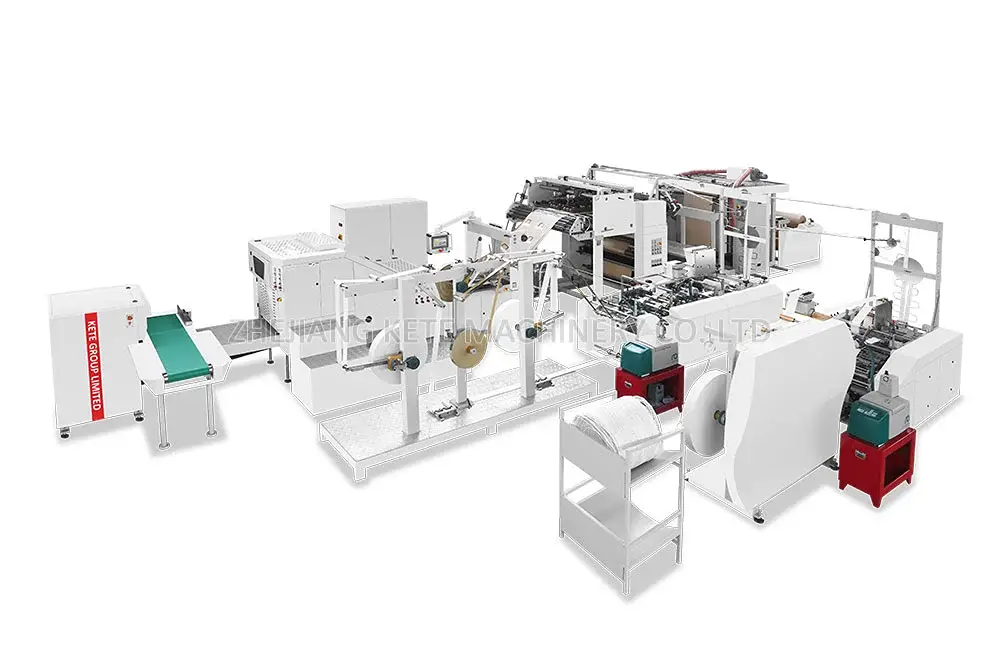

KETE: Your Expert Partner for Slitting Rewinding Solutions

Since 2011, KETE has been a trusted leader in slitting rewinding solutions, offering cutting-edge technology to meet your production needs. Here’s why KETE is the ideal choice for your business:

Versatile Material Compatibility

Effectively process materials such as plastic films, paper, aluminum foil, and non-woven fabrics, catering to a wide range of industries like flexible packaging, medical packaging, and food packaging.

Precision Slitting

Adjustable slitting widths as narrow as 5mm, with servo-controlled accuracy of ±0.1mm, ensuring clean edges, consistent quality, and minimal waste—even at high speeds.

High-Speed Efficiency

Achieve speeds of up to 500 meters per minute, allowing you to easily manage large orders and meet tight delivery deadlines.

Comprehensive Automation

Our advanced slitting machines handle unwinding, rewinding, tension control, and length counting automatically, reducing manual labor while enhancing production efficiency and precision.

Exceptional Capacity

Accommodates rolls up to 2600mm in width and 1400mm in diameter, reducing material changes and boosting production efficiency.

User-Friendly Design

Intuitive LCD touchscreen interface simplifies operation, enabling even novice users to run the machine with ease while minimizing training time and errors.

Durable & Reliable

Built with high-quality, long-lasting components, our machines deliver reliable performance in any environment with low maintenance costs.

Partner with KETE to optimize your slitting rewinding process, reduce waste, and scale your production to new heights. Reliable, precise, and efficient—KETE is your ultimate solution provider!

Conclusion

Choosing the right slitting rewinding machine is a critical decision that directly influences operational efficiency, product quality, and profitability in any web converting process. This guide has outlined the fundamental functions, working principles, and diverse types of these essential machines, categorized by slitting methods, winding techniques, and rewind configurations. We’ve explored their wide-ranging applications across industries and highlighted the key factors—from material properties and roll specifications to production demands and manufacturer support—that must be carefully weighed during the selection process.

Ultimately, the optimal slitter rewinder is one that aligns seamlessly with your specific materials, application requirements, and production goals. Investing the time to thoroughly assess your needs and understand the available technologies will lead to a choice that maximizes productivity, minimizes waste, and ensures the customer satisfaction and consistent quality your customers expect. We encourage you to use the insights provided here as a foundation for making an informed decision and to consult with experts, like the team at KETE, to find the slitting rewinding solution that will drive your success.