Brand recognition is essential in the modern competitive market. Custom printed paper bags are not merely packaging, they are mobile billboards, they are a continuation of your brand philosophy and values. This article will discuss everything about paper bag printing, including the selection of materials and printing techniques, design advice, and cost factors, so you can design the ideal brand packaging.

Why Businesses Choose Printed Paper Bags

There are numerous reasons why businesses use printed paper bags. The primary objective is always to enhance brand image and competitiveness in the market.

- Boost Brand Recognition: Paper bags with your brand’s logo, slogan, or unique design quickly catch consumer attention. This strengthens your brand in their minds.

- Marketing and Advertising: Every custom paper bag acts as a walking advertisement. This spreads your brand message widely.

- Enhance Customer Experience: Custom paper bags are beautiful and of high quality that enhances the shopping experience of the customer. They demonstrate the professionalism and care of the brand.

- Environmental Awareness: Paper bags are more environmentally friendly as compared to plastic bags. They are biodegradable and recyclable. This satisfies the consumer need for sustainability and assists companies to create a favorable social responsibility image.

- Competitive Differentiation: Distinctive packaging design is the most important thing to remain different and retain customers in a market where products are similar.

Types of Paper Bags and Their Printing Suitability

Choosing the right paper bag type is the first step to successful printing. Different paper materials and bag styles affect the print outcome differently.

| Paper Bag Type | Common Basis Weight | Printing Suitability | Features |

| Kraft Paper Bags | 80-150gsm | Flexo, Screen, Offset, Digital | Eco-friendly, durable, natural look; good for simple designs |

| White Cardboard Bags | 180-350gsm | Offset, Digital; good for rich colors | Smooth surface, vibrant print; often used for premium packaging |

| Coated Paper Bags | 157-300gsm | Offset, Digital; good for fine printing | Smooth surface, high gloss; good color reproduction |

| Art Paper Bags | 120-250gsm | Offset, Screen, Digital | Various textures, unique feel; artistic print results |

| Laminated Paper Bags | Various papers with laminate | Offset, Digital | Adds water resistance, durability; enhances gloss or matte finish |

Popular Printing Methods and Machines for Paper Bags

Understanding different printing methods and their machines helps you pick the best printing solution. You can find more info on each method below.

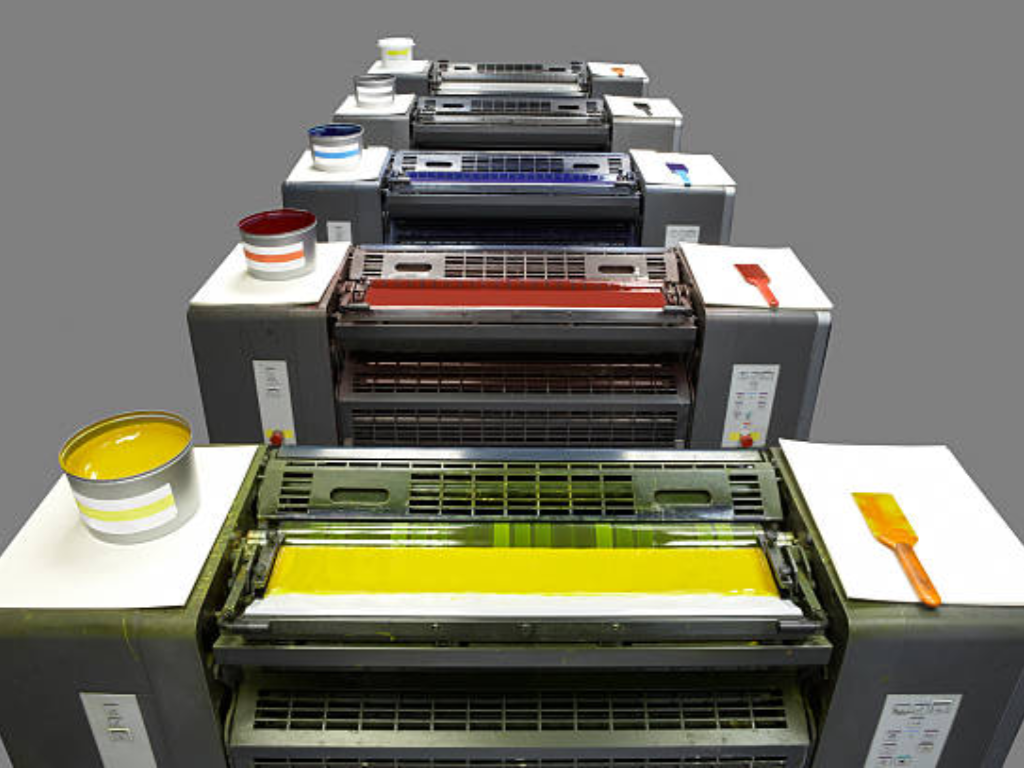

Offset Printing (Lithography)

Offset printing is an indirect process. The ink is put on a plate and then on a rubber blanket and then on the paper. It is defined by high quality of images and color reproduction. It is the most appropriate method in high volume and high precision printing.

Offset Printing Advantages:

- High Quality: The pictures are clear and sharp. Colors are very precise. Good in jobs that require small details.

- Cost-Effective: Good for large print runs, leading to lower cost per sheet.

- Wide Material Range: Can print on many types of paper and non-absorbent materials.

Offset Printing Disadvantages:

- Platemaking Cost: High initial cost for plates, not good for small runs.

- Setup Time: Longer preparation time, complex process.

Recommended Machine: Heidelberg Speedmaster XL 106

As an industry insider, we say: Heidelberg Speedmaster XL 106 is an offset printing benchmark. We suggest it since it provides the highest printing accuracy and manufacturing productivity. This machine is very automated and minimizes human interference and mistakes. It also enables rapid job changes, which is essential to print shops that require high productivity. It is flexible in terms of the type of paper and the thickness of paper that it can handle, which makes its print quality stable and consistent. Although the initial cost is high, its long-term stability, low breakdown rate, and high print quality are very rewarding to the clients who require large-volume and high-quality printing. Speedmaster XL 106 is a perfect solution to high-end commercial and packaging printing.

Key Parameters and Features:

- Print Format: Max 70 x 100 cm, suits various size needs.

- Speed: Up to 18,000 sheets/hour, very high production efficiency.

- Automation: Equipped with Intellistart 3, Prinect Inpress Control, and other smart automation systems for presetting, auto-registration, color control, and cleaning.

- Eco-friendly: Energy-saving design, supports alcohol or reduced-alcohol printing.

- Material Adaptability: Handles a wide range of materials from thin paper to thick cardboard.

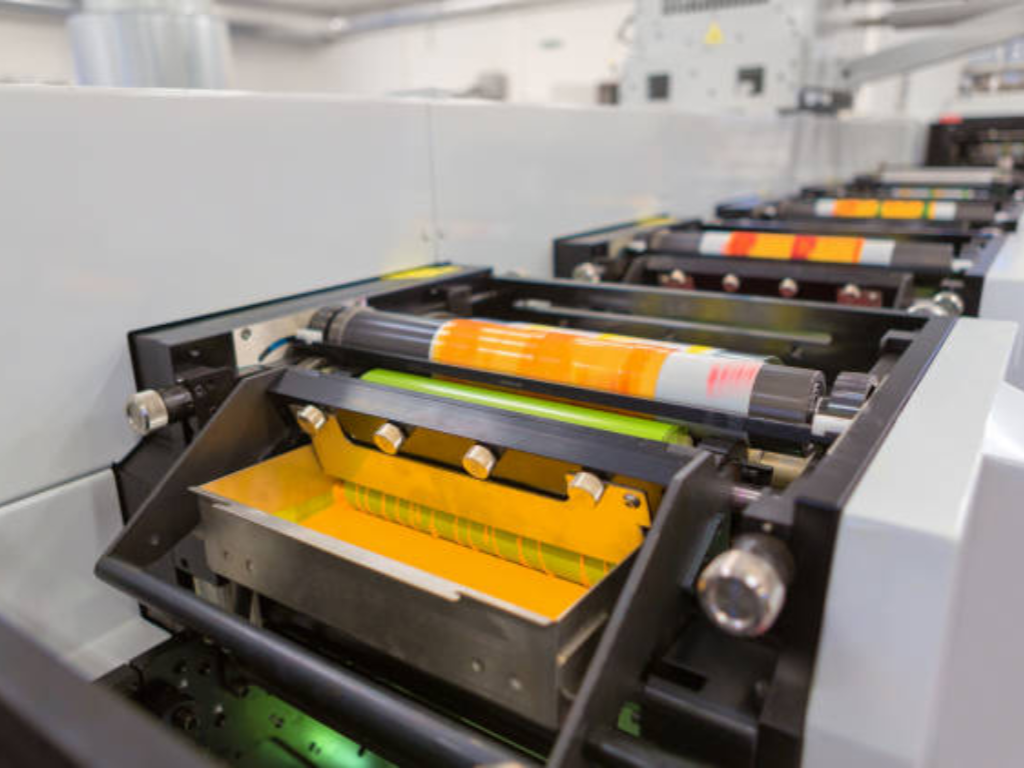

Flexographic Printing

Flexographic printing involves a flexible relief plate. The ink is transferred directly to the substrate by the roller. It has high printing speed and drying of the ink. It is not very expensive. This is a good technique to use when printing on non-absorbent materials and rough surfaces. It is extensively applied in the packaging sector in large-volume production.

Flexographic Printing Advantages:

- Fast Speed: High production efficiency, good for large-volume packaging printing.

- Lower Cost: Plate and ink costs are lower than offset, good operating cost efficiency.

- Wide Material Adaptability: Especially good for flexible materials like films, non-woven fabrics, and kraft paper.

- Eco-Friendly: Often uses water-based inks, low VOC emissions.

Flexographic Printing Disadvantages:

- Print Precision: Slightly less precise in fine details and color gradients than offset.

- Platemaking: Although plate material cost is low, plate making requires some expertise.

Recommended Machine: KTFP-S200P KETE Paper Roll Printing Machine

Being a soft packaging industry professional with more than 30 years of manufacturing experience, the paper roll printing machine of KETE is top-notch in flexographic printing. The raw materials that our machines can process are plastic film, paper, non-woven fabric, and metal foil. This gives broad material compatibility to your paper bag printing.

The printing machines of KETE are highly efficient, stable, and highly automated. They are versatile to different production requirements and facilitate one-stop solutions of printing, laminating, slitting, and bag making. We employ electrical parts of world-known brands such as Delta, Schneider, and Panasonic. This guarantees high performance and reliability.

KETE is focused on offering affordable packaging equipment. We have sold more than 2,000 machines per year and our products are exported to more than 80 countries. We understand that quality is the most important factor to customer confidence. Therefore, we are adhering to ISO 9001 quality management system. Our equipment is all CE certified and some of our products are RoHS compliant. KETE provides a full range of customer support, including pre-sales consulting and visual progress reports during production, 1-2 year warranty, and on-site installation. This makes your investment worthwhile. When you select KETE, you do not only obtain high-tech equipment but also a stable and reliable partnership.

Key Parameters and Features:

- Print Width: Customizable based on client needs, typically covers main paper bag production widths.

- Print Colors: Supports multi-color printing, usually 4-8 color configurations for complex designs.

- Speed: Fast operation speed, suitable for large-volume continuous production.

- Automation: Equipped with automatic tension control and auto-registration systems. This reduces manual intervention and improves printing precision and stability.

- Material Adaptability: Excellent tension control system, compatible with various roll materials of different thicknesses and stretch properties.

- Energy-Saving Design: Uses efficient drying systems and energy-saving motors.

Screen Printing

Screen printing uses a mesh screen to transfer ink onto the substrate. Its strengths include a thick ink layer, vibrant colors, strong tactile feel, and good opacity. Screen printing is adaptable to many substrates, including paper, plastic, textiles, and metal. It is especially good for small batches, special effects, or irregular shapes.

Screen Printing Advantages:

- Thick Ink Layer: Prints have rich colors, strong tactile feel, and good opacity.

- Wide Material Adaptability: Can print on almost any flat surface material.

- Special Effects: Easy to create matte, puffed, glow-in-the-dark, and other special print effects.

- Cost-Effective for Small Batches: Lower plate costs than offset, good for small custom runs.

Screen Printing Disadvantages:

- Slower Speed: Production efficiency is lower than flexo and offset.

- Precision: Less precise in fine details and multi-color registration than offset and digital printing.

Recommended Machine: MR Challenger III D Automatic Screen Printing Press

As an industry insider, we say: The MR Challenger III D is highly recommended to clients who desire high quality, high-ink coverage or special effect printing on paper bags. This is an automatic screen printing machine that addresses the low efficiency of the traditional screen printing. It significantly increases productivity by automation and multi-color set up. Its accurate registration feature is particularly significant in complicated designs that require multi-color printing. The durability and stability of the MR Challenger III D is well known in the market. This implies reduced maintenance and increased service life. Although screen printing is slower than flexo or offset in general, when it comes to small to medium runs of paper bag products requiring a distinct visual and tactile impression, this machine is unrivaled in terms of value.

Key Parameters and Features:

- Print Colors: Multi-color configuration, e.g., up to 18 colors, for complex designs.

- Print Speed: Up to 7200 pieces/hour, boosts production efficiency.

- Print Format: Adapts to large size printing, suits various paper bag specifications.

- Automation: Automatic loading, printing, drying, and unloading systems.

- Registration Accuracy: High-precision registration system ensures accuracy for multi-color printing.

- Ink Types: Compatible with water-based, solvent-based, UV, and other screen printing inks.

Digital Printing

Digital printing is not plate-based. It directly prints digital images on the substrate. Personalization and variable data printing are its greatest strengths. It allows small runs, variety, and print-on-demand, and rapid delivery.

Digital Printing Advantages:

- No Plates Needed: Significantly reduces initial costs and preparation time.

- Personalization and Variable Data: Each print can be different, great for customization and marketing campaigns.

- Cost-Effective for Small Batches: Perfect for on-demand printing, avoids inventory buildup.

- Fast Delivery: Simplified process allows for quick production.

Digital Printing Disadvantages:

- Cost Per Unit: For large print runs, the cost per unit is higher than offset and flexo.

- Color Reproduction: May not match the special color gamut reproduction of traditional offset printing.

Recommended Machine: Canon imagePRESS V900 Series

As an industry insider, we say: The Canon imagePRESS V900 Series is a machine we at KETE have a lot of respect towards, as it is a machine that can be used by paper bag printing companies that require fast proofs, small custom batches, or personalized marketing. It has an excellent performance in color accuracy and image quality, and it satisfies high-standard design requirements. One of the strengths of the machine is its flexibility. It can quickly change paper size and weight, and there are no lengthy set-up times. This implies that your clients will be able to respond to the changes in the market promptly and launch customized packaging. The V900 Series is an efficient and high-quality solution to clients who are interested in short-run, high-frequency, and differentiated printing without compromising quality.

Key Parameters and Features:

- Print Speed: Up to 90 pages/minute (V900), provides high production capacity.

- Color Quality: Excellent image resolution and color consistency, supports various color profiles.

- Paper Adaptability: Handles various papers from envelopes to large formats, and from thin to thick (e.g., 52-400gsm).

- Automation: Features automatic calibration and registration systems, simplifies operation, ensures output quality.

- Variable Data Printing: Supports complex personalized and variable data printing jobs.

Finishing Touches and Special Effects

Special effects and finishing touches on the paper bags can also add a lot of value and attractiveness to the bags.

- Lamination: Available in gloss or matte finishes, protects the printed surface, increases durability, and enhances texture.

- Hot Stamping/Foil Stamping: Deposits metallic foil on the surface of the paper bag with the help of heat and pressure. This gives a luxurious, high-end effect.

- UV Coating: UV varnish is applied to part or all of the surface. It is cured with UV light, which gives it a high-gloss look in certain places, enhancing the visual appeal.

- Embossing/Debossing: Dies are used to produce raised or recessed designs on the surface of the paper. This gives it a touch of texture and a third dimension.

- Die-Cutting: Trims the edges of the paper bag or makes windows of a certain shape. This gives it design flair and interest.

Creative DIY: How to Print on Paper Bags?

DIY paper bag printing is a cheap and entertaining alternative to printing paper bags in small batches or on a personal level.

- Prepare Tools: Blank paper bags, stamps/vinyl decals/screen printing kit, acrylic or fabric paints, brushes/squeegee.

- Design Pattern: Create your stamp or screen printing design.

- Print: Coat the stamp or screen with paint. Then press or squeegee on the paper bag.

- Dry: Let the paint dry completely.

- Set Color (Optional): Some paints need heat setting for better durability.

Inks for Printing on Paper Bags

The selection of ink influences the quality of print, environment and cost.

- Water-Based Inks: Non-toxic, environmentally friendly, no VOCs (Volatile Organic Compounds), quick drying. These are popular.

- Solvent-Based Inks: Extremely quick drying, bright colors, good adhesion, and VOCs. Less eco-friendly.

- UV Inks: Cure instantly under UV light, no VOCs, wear-resistant, scratch-resistant, high color saturation.

- Soy/Algae Inks: These are renewable resources. They are more environmentally friendly and align with the sustainability trends.

Designing Your Perfect Printed Paper Bag

Your paper bag will be unique with a good design. Pay attention to the graphics used.

- Define Brand Tone: What is your brand luxury, eco-friendly, fun, or minimalist? The design should be in line with your brand image.

- Choose Right Size and Material: Select the size and material of the bag depending on the use and weight capacity. Choose the appropriate size and type of paper.

- Logo and Information Placement: The logo must be visible. It is also possible to include such important details as the web site, social media, and phone number.

- Color Scheme: Select colors according to the visual identity (VI) system of your brand. Make sure that the colors in print are as expected.

- Font Selection: Use an easy-to-read font that fits your brand’s style.

- Consider Handle Type: Rope handles, paper twist handles, flat paper handles, or die-cut handles all affect overall design and cost.

Paper Bag Printing Costs: What to Expect

The cost of printing on paper bags varies with a lot of factors. Knowledge of these factors assists you in budgeting and decision making.

- Quantity: The more the batches, the cheaper the unit cost because the fixed costs such as plate making and machine setting up are distributed.

- Size and Material: Bigger bags and heavier paper grammage tend to be more expensive. Special materials such as art paper are also costly.

- Printing Method: Flexo and offset are suitable when printing in large quantities, and the unit cost is low. Digital is great on small, custom runs, but unit cost may be more. Screen printing is used on small runs and special effects.

- Print Colors: The more the colors, the more the ink and printing plates, which increases the cost.

- Finishing Touches: Lamination, hot stamping, UV coating, and other special processes add extra cost.

- Design Fees: In case the printer offers design services, then there is a design fee.

- Shipping Costs: Especially for international shipping, consider freight and duties.

Maximizing ROI: Smart Machine Investment

Investing in the appropriate printing equipment is essential to businesses that want to achieve long-term, efficient, and customized packaging solutions in order to maximize cost-effectiveness and profit. As an illustration, the flexographic printing machines of KETE are capable of printing various materials and offer one-stop services including printing and bag making. This assists companies to manage the cost of production and guarantees quality and speed of production. This puts them at a big advantage in a competitive market. It is usually more economical to purchase your own equipment, particularly when high volumes are required, than it is to outsource on a regular basis. It also provides you with a greater control over the production process and quality of the product.

Legal and Safety Considerations

In the process of printing paper bags, it is crucial to adhere to the applicable laws and safety regulations. This includes ensuring proper protective equipment is used in industrial environments.

- Food Safety: In case of food packaging, inks and materials should be food contact safety.

- Environmental Regulations: Understand and follow local environmental rules on VOC emissions, waste disposal, and recycling.

- Intellectual Property: Make sure your logos, patterns, and designs do not infringe on others’ intellectual property rights.

- Workplace Safety: Labor safety regulations should be observed in print factories to guarantee the safety of the operators.

Conclusion

Custom printed paper bags are a good way of improving brand image, customer experience, and successful marketing. This will be a value addition to your brand in the long run, such as choosing the right printing methods and machines, and designing all the details. No matter whether you need mass production or individual solutions, this is one of the most significant pieces of information that will help you to make informed decisions and make your brand shine in the market.

Do you now understand better how to personalize your perfect paper bags?