For any company that deals with large rolls of paper, packaging or printing materials, acquiring a paper slitter is not just a mere acquisition of equipment but a strategic investment that can greatly affect the operations of the business. When it comes to handling large paper rolls, small paper rolls, or when you need precise slitting for various materials, it is important to select the right machine. Knowledge of how a paper slitter operates, the various types that are available in the market, and how to choose the right one will not only enhance productivity, but it will simplify your processes. In this guide, we will discuss all the important aspects that you should know before making a purchase to make the right decision.

What is Paper Slitter?

A paper slitter is a machine that has been designed to cut large rolls of paper into smaller rolls or sheets with specific sizes. This is crucial in industries like packaging, printing and converting where there is a need for sliting down large jumbo rolls into manageable sizes with high precision thereby making the same ready for further processing.

The reason the paper slitter is so important lies in its versatility. Whether it is manufacturing, packaging or other applications in the paper products sector, this machine ensures that companies obtain the exact size and quality of papers they require to maintain smooth operations flow. For insiders, It’s not just about cutting paper; it’s about cutting it right.

How Does a Paper Slitter Work?

A paper slitter is a machine that is used to slice large rolls of paper into smaller and more manageable widths by using sharp blades or knives. The process starts with placing a jumbo roll on the machine and unrolling and aligning it before cutting it into the required widths and thickness. The cutting width can also be adjusted in order to meet the production requirements of the specific product. After slitting, the paper strips are then rewound on smaller cores to make them ready for multiple purposes, like POS rolls, packaging supplies, or other printing processes.

Some of the slitting machines are provided with HMI (Human-Machine Interface) for better control of the machine. This interface enables the operators to track the real-time data of the speed and the blade settings and other parameters of the machine, which enhances precision and productivity.

Types of Paper Slitters Available

It is crucial to know the various types of paper slitters since each type has its own characteristics that may be suitable for a specific production process. Here is a brief description of the most common types of paper slitters:

| Type | Advantages | Speed | Applications |

| Manual Slitters | Cost-effective | Low speed | custom cutting, craft manufacturing |

| Automatic Slitters | High efficiency, reduces human error | High speed (up to 500 m/min) | Printing, packaging, paper converting |

| Duplex Slitters | Dual-direction cutting, increases throughput | High speed (up to 500 m/min) | Packaging, paper converting, film slitting |

| Simplex Slitters | Lower cost, simpler tasks | Medium speed (100-300 m/min) | Small production lines, simple paper slitting, custom production lines |

| Rotary Slitters | High precision, fast | High speed (up to 500 m/min) | Packaging, printing, advertising industries |

| Razor Slitters | Sharp blades for precise cutting | Medium speed (100-300 m/min) | Fine cutting, small rolls, thin paper or films |

| Vertical Slitters | Space-saving, compact | Medium speed (100-300 m/min) | Small production lines, material conversion |

| Horizontal Slitters | Suitable for larger rolls and complex tasks | Medium speed (100-300 m/min) | Packaging industry, film processing, medical material handling |

| Laser Cutters | Ultra-precise | Low speed | Decorative paper, custom designs |

Note: The data in the table may differ depending on the brand, model, or technology. Before making a purchase, be sure to go through the technical manual of the specific product and the specifications given by the manufacturer to ensure that the equipment meets your requirements.

Manual Slitters

Manual slitters are the simplest type of slitting machines where the operators have to set the controls and feed the paper rolls themselves. They are cheaper but their production rate is low, and they are not as automated and efficient as other machines, which makes them unfit for mass production and ideal for small production volumes. Manual slitters are usually employed in situations where accuracy is not very important and the size of paper is relatively standard.

Automatic Slitters

Slitters that operate automatically are built for mass production. The process has an automated loader, a cutter, and a rewinder, which increases effectiveness and consistency. Requiring no human interruption, these machines are perfect for large-volume production, providing effortless and rapid cuts. The automatic features help lessen human errors and system pauses, increasing productivity, which is critical in most industries.

Duplex and Simplex Slitters

Duplex slitters are those that cut the paper in two directions at the same time and are therefore useful in high production environments. They are often used when speed and accuracy are important. Such machines are commonplace where precision and speed are both needed. Simplex slitters cut in only one direction and are often preferred for less complex tasks or smaller runs. Although simple slitters are cheaper, duplex slitters are faster and more efficient, especially in large production facilities.

Rotary Slitters

Rotary slitters employ rotating blades to cut the paper and this makes the cut to be clean and smooth. This type of slitter is common in industries such as printing and packaging since accuracy is very important in the process. The rotary slitter is ideal for these sectors due to its high speed and capacity to work on thick materials.

Razor Slitters

Razor slitters use thin and sharp blades to make thin and clean cuts. They are ideal for cutting small rolls or sheets that need a high level of accuracy in the cutting process. Razor slitters are used where precision is important, for instance in specialty papers or where the final product requires a fine cut with no jagged edges. This makes them suitable for use in applications that need both cleanliness and accuracy of the cuts.

Vertical/Horizontal Slitters

Vertical slitters are those that operate by placing the paper in a vertical position and then cutting it, while horizontal slitters cut the paper by placing it horizontally, thus the name. Vertical and Horizontal slitting choices are made according to the position of the production line and the nature of the material to be cut. Vertical slitters are more compact in design whereas horizontal slitters are used when there are bigger rolls or if the handling of the material is more complex. Both types are perfect for multiple production needs depending on the allocated space and the type of material that has to be worked on.

Laser Cutters

Laser cutting is the most advanced slitting technique that uses laser beams to cut paper with a high level of precision. While they are comparatively slower than conventional slitters, they offer very thin and accurate cuts that are suitable for detailed work. Laser cutting is widely used in industries like custom designing, decorative paper products, and packaging industries where accuracy and cutting patterns are very important. It is also important to note that they are able to produce intricate shapes and patterns that are not possible with other cutting tools.

The various types of paper slitters have their benefits depending on the production capacity, speed, and the type of material to be slit. Thus, the knowledge of these differences will help businesses to choose the right machine for their needs and achieve the maximum performance and quality of the work done.

What is Paper Slitter Used For?

A paper slitter is a piece of equipment that is used in industries that deal with large rolls of paper or any other flexible material. It has several important functions, all of which are designed to meet the needs of various industries. The following are some of the uses of paper slitter machines:

Printing Industry

Accuracy is crucial in the printing business. Paper slitters are employed to cut large rolls of paper into the right size for use in printing presses for various purposes. For instance, in the labeling of consumer products, a slitter is used to cut large rolls of paper into smaller ones that are ready for printing of quality labels and affixing on the products without much time being wasted. These machines are very accurate, and this helps in reducing wastage while at the same time maintaining quality which is important in large scale printing.

Packaging Industry

The packaging industry depends on paper slitters to cut large paper rolls into narrower widths that can be used in packaging, labeling or preparing materials for transportation. Paper slitters can cut paper as narrow as a few millimeters, which makes it possible for businesses in packaging to save on their material and increase their productivity, especially in industries where packaging materials have to be prepared in a short span of time.

Paper Converting Industry

In paper converting, large rolls of paper are converted into smaller usable products. Slitting machines are used to cut paper into the required sizes and shapes that are used in the production of notebooks, tissues, or any other paper products. The slitter enables accurate cutting, which is important for ensuring that quality is kept at a high level throughout the production of all the products.

Advertising and Design Companies

Paper slitters are essential in the advertising and design fields where accuracy and flexibility are crucial for specific jobs. A slitter meets the requirements of the advertisement industry by providing precise cutting for business cards, posters, and other promotional material, thus enabling high quality custom designs.

Publishing Industry

In the production of books, magazines, newspapers, a paper slitter is a tool that is very important to the publishers. It is used to cut large rolls of paper into the right width for other processes such as folding and binding. On-time and precise slitting enables the publishers to meet their production schedules and at the same time avoid wastage of paper.

In conclusion, paper slitters are essential in many industries as they help in cutting large rolls of paper into the required sizes. They assist in managing the production processes, increasing productivity, and ensuring product quality in businesses.

How to Choose the Right Paper Slitting Machine?

While choosing the paper slitter rewinder machine, the following factors should be taken into consideration to meet the specific requirements of the business. The following are the aspects of concern:

Material Compatibility

Ensure that the machine can accommodate the type, thickness, and rigidity of the paper you are using. Some machines are designed for thicker or sturdier materials, while others are more suited for thin and flexible papers or films. If you need to cut different types of paper, it’s best to choose a versatile machine that can handle a variety of materials.

Cutting Width and Length

Verify that the machine is able to handle the cutting widths and lengths required. Slitters usually have adjustable blades to accommodate different sizes. This guarantees that varying material or paper widths can be handled efficiently for various applications, thus increasing production and reducing waste.

Cutting Precision and Accuracy

It is crucial to achieve high accuracy, especially in such fields as printing or packaging, where even the slightest deviation can lead to problems. Seek for machines that will provide a high level of accuracy and repeatability, with low tolerance. This helps in getting better cuts, which minimizes waste of material and enhances the quality of the final product, which is important in meeting production quality.

Cutting Speed

For high volume operations, you should consider a machine that can feed many paper rolls at a time and process them in the shortest time possible. Select a slitter that can accommodate the required volume of slitting without having to shut down often because this is expensive. Machines with speeds up to 500 meters per minute are typical for high-volume operations.

Ease of Use

Consider machines that have an easy to understand HMI interface. It assists the operators in managing the machine in a proper way and reduces chances of human interference, thus enhancing productivity.

Maintenance and After-Sales Support

In selecting the paper slitter rewinder, it is also important to consider the after-sale service and technical support from the manufacturer. This coupled with maintenance is crucial in ensuring that the machine lasts long and runs efficiently in the long run. Maintenance and efficient support ensure that the equipment does not break down frequently and that production is not interrupted frequently.

Budget

Last but not least, ensure that the capabilities of the machine are not out of your reach financially. More expensive machines have better speed, precision, and extra features. However, there are cheaper models that are also available in the market that can also be used to meet the above requirements. It is also important to look at the long-term costs of operation, such as the costs of maintenance and energy consumption to get the best value for your money.

Based on these factors, one can select a paper slitter rewinder that will suit the production line and be efficient in the long run.

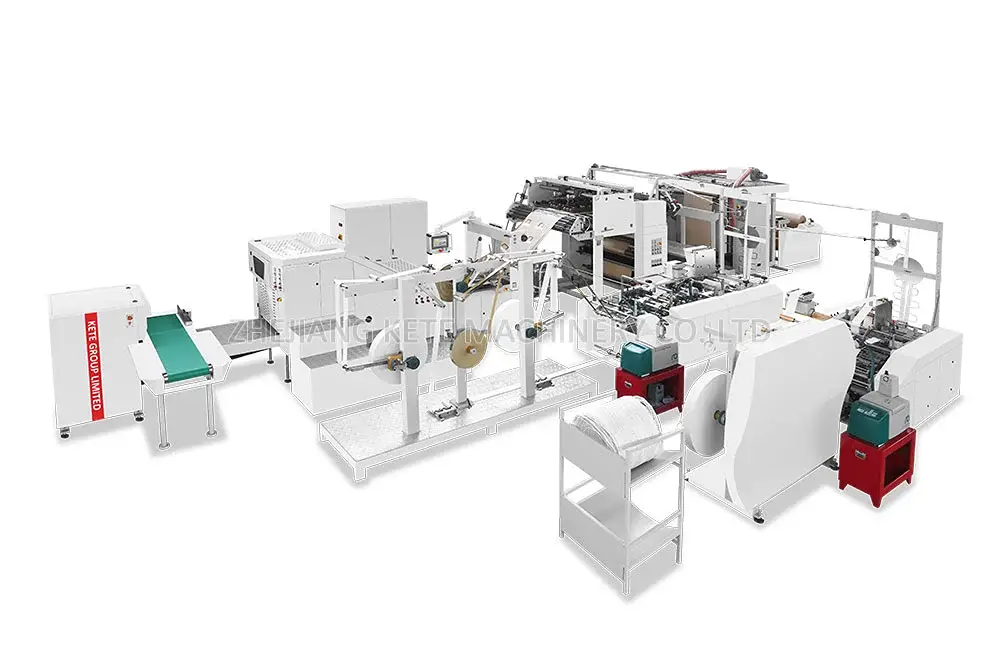

Top Paper Slitters to Consider

KETE is among the top China paper slitters suppliers with years of experience in the industry. We offer complete solutions for slitting and have various models to suit your needs, each model has its own characteristics. Here are some of the different paper slitter models that we have for your reference, and we hope it will be helpful to you.

| Model | Raw Material Width | Slitting Techniques | Max. Unwind Diameter | Max. Rewind Diameter | Min. Slitting Width | Max. Mechanical Speed |

| KTSM-CS300 | 1100/1300mm | Rotary Shear Cut | Φ1400mm | Φ600mm | 5mm | 300m/min |

| KTSM-C350P | 1300/1600mm | Rotary Shear Cut | Φ1200mm | Φ1000mm | 50mm | 350m/min |

| KTSM-C400G | 1600/1800/2000/2600mm | Rotary Shear Cut | Φ1700mm | Φ1500mm | 30mm | 400m/min |

| KTSM-C600G | 1800/2600mm | Rotary Shear Cut (Pneumatic) | Φ1600mm | Φ1300mm | 30mm | 600m/min |

| KTSM-S600 | 2000/2600mm | Rotary Shear Cutter | Φ1800mm | Φ1300mm | 100mm | 600m/min |

Key Maintenance Practices for Paper Slitters

Maintenance is crucial to ensure the proper functioning of your paper slitter rewinder and to maximize its usage time. Here are some of the best practices that should be followed:

Cleaning and Routine Inspections

Ensure that the machine is clean to avoid accumulation of paper dust, debris and other materials that may hinder the efficiency of the machine. Regularly clean blades, rollers, and key components. While cleaning, we should also perform visual checks to see if there are any signs of wear, any noises, or any signs that could indicate a problem that may lead to a failure. This is because early detection of the problem will help avoid expensive repair costs.

Blade Inspection and Replacement

Cutting tools are very important especially blades that are used in cutting processes. It is also important to inspect the blades for signs of dullness, damage, or wear and tear. Blades that are blunt or worn out can cause the cuts to be off and place extra stress on the equipment. Blades should be replaced when they are worn out to ensure that the cutting is done efficiently.

Lubrication

Lubrication of the parts such as gears, bearings, and shafts is crucial to minimize friction and wear. It is advisable to use the recommended lubricant by the manufacturer to avoid overheating and to increase the lifespan of the machine.

Tension and Calibration Checks

Make sure that the tension settings of the machine are set to the right level for the material that is being used. It is recommended to calibrate the system from time to time to ensure that the cutting and winding process is accurate. This is because if the tension is set at the wrong level, then it will lead to poor cuts or paper jams.

Software and System Updates

If your paper slitter has an HMI or an automated system, make sure that the software is updated frequently. This makes the system more efficient and compatible with the new features hence improving the performance of the machine.

If you follow these simple practices, you will reduce repair costs, minimize downtime, and keep your paper slitter rewinder in peak condition for years to come.

FAQ

Q: What is the average cost of a paper slitter?

A: The cost of a paper slitter can vary depending on the size, capabilities, and brand of the machine. On average, you can expect to pay anywhere from $5,000 to $50,000 for a quality machine. Higher-end models with advanced features like HMI systems, high-speed operations, and precise cutting capabilities tend to be more expensive.

Q: Can a paper slitter be used for materials other than paper?

A: Yes, a paper slitter rewinder can often handle a variety of materials, including foil, plastic films, and even textiles. However, it’s important to check the machine’s specifications to ensure compatibility with the material you plan to use.

Q: What are the key features to look for in a paper slitter?

A: When selecting a paper slitter, look for features such as precision cutting, adjustable width settings, ease of use with an HMI, and high-speed capabilities. The ability to handle different types of materials and offer minimal downtime is also essential for efficient operation.

Q: Are there any safety precautions when using a paper slitter?

A: Yes, safety is crucial when operating a paper slitter. Always follow the manufacturer’s safety guidelines, wear appropriate protective gear, and ensure that the machine is properly maintained to avoid accidents. Operators should also be trained to handle the machine safely.

Conclusion

Selecting the right paper slitter rewinder machine can greatly enhance operations for companies in the printing, packaging, and other related sectors. Knowledge of how the machine works, the various types that are available and the factors to consider when choosing the right one will assist in making the right decision. A good slitter is not only effective in its operation but also increases production and minimizes time wastage, making your business more competitive. Don’t miss the opportunity to make the right decision and open the door to the growth and development of your processes!