Introduction

The label processing industry is a crucial support for many industries, providing efficient functioning in such fields as trade, transportation, medicine, and production. Labels are not only used for branding purposes but also for conveying important information about the product, its usage, and compliance with legal requirements. As the packaging market expands at a fast pace across the world, the need for new and improved labels is on the increase.

Current market trends show that there is a growing demand for high-quality, sustainable, and bespoke labels to meet the changing needs of the market players. With more and more regulatory pressure and competitive challenges, the need for accurate and fast label processing has never been greater. Efficient production of labels also guarantees not only operational efficiency but also the ability to meet dynamic market needs.

What is Label Converting? The Complete Process Explained

Label converting is the process of converting face stock, adhesive layers, and releasing liners into functional and high-quality labels for use in various applications. This involves steps such as printing, cutting, laminating, and finishing in order to produce labels that are made to specific client requirements for various uses such as retail, health, transportation, and production industries.

Label converting is crucial because it transforms basic materials into products that have practical uses as well as ornamental value. Labels cannot be just informative or contain branding but also need to be resistant to such factors as heat, moisture, or friction. Achieving this requires a highly precise and efficient production process, which can be broken down into the following key stages:

Material Selection

The choice of face stock, adhesive, and release liner is the main determinant of success in label converting business. Every part must be suitable for the intended application if it is to be durable, resistant to the environment, or recyclable. For instance, the adhesive used in frozen products must be able to stick at very low temperatures, while that used in biodegradable labels must be biodegradable. Thorough material testing at this stage ensures compatibility and durability, preventing performance issues under real-world conditions.

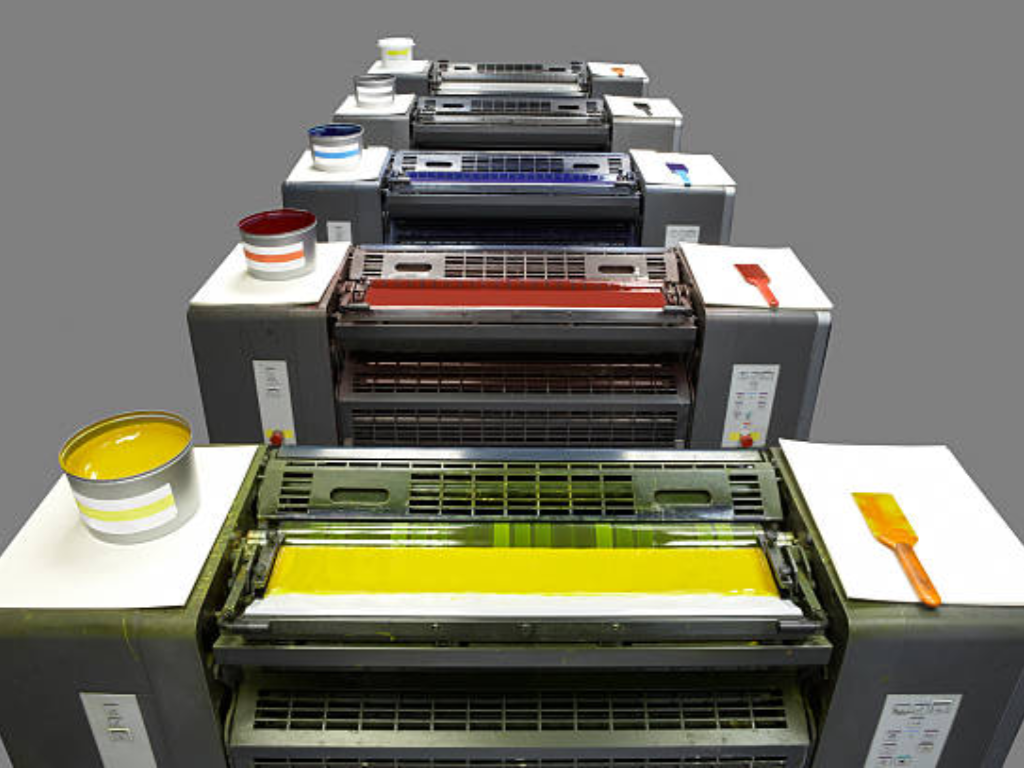

Printing

It is important to achieve high-quality prints in order to get sharp, bright, and long-lasting images. Digital printing is particularly appropriate for specialty, shorter-run jobs, while flexographic or offset printing is more economical for high-volume orders. Hence print quality entails standards such as color deviations not exceeding Delta E ≤ 2, high resolution, and good alignment. The routine press inspection and readings from the spectrophotometer minimize cases of errors in the process, thus producing favorable prints.

Die Cutting

Labels are then cut to the desired sizes and these sizes and shapes are achieved through die-cutting. Accuracy is important because labels that are cut poorly may not apply well or may be wasted. Must be checked frequently and monitoring the cutting blade sharpness, ensuring that the shapes are uniform and using digital measuring gadgets to achieve tolerances of up to ±0.1mm.

Laminating and Coating

In order to improve the durability and appearance of labels, need to be laminated or coated. Laminates give protection against moisture, UV light, and wear and tear, coatings create a visual effect such as shiny or dull. The quality control tests conducted here include adhesion strength tests, scratch tests, and film thickness tests. Such steps guard against poor finish such as peeling and other possible defects which could compromise the finish and durability.

Slitting and Rewinding

After laminating labels are cut or slit into smaller reverse rolls or sheets for storage and usage. Special attention should be paid to proper alignment and tension control during its performance since this can lead to edge damage, wrinkles, or uneven rolls. In this step, quality control performers need to check roll alignment on top of inspecting for uneven tension and the absence of edge damage or adhesive leakage on labels.

Inspection and Quality Control

It confirms the correctness of labels as per customers’ specifications and checks that they are not flawed in any way. Some of the common quality problems are wrong alignment of the printing, some parts of the die cutting that are not cut properly, smudging, or improper application of adhesives. Today’s inspection systems employ cameras and sensors to identify defects, and the software is able to recognize errors on the fly. Operators also perform random checks on selected packs to ensure that the color is correct, and the print is clear and well aligned.

To add control with the aim of increasing quality and accountability, most converters implement use traceability systems. Production detail is described in batch numbers or barcodes, which are used on labels. It helps in making it easier to resolve such problems in the occurrence of complications.

Packaging

The last process is to pack these labels so that they do not get damaged when in storage or in the process of shipping. Accompanying labels are protected from dust, moisture, and contaminants through the use of boxes or shrink wrap. Detailed labeling allows the products to be easily identified by providing such records as batch number, order number, and specifications on the packages. Proper stacking and proper secure means of transport are used, and labels are delivered in the perfect state and can be used immediately.

Label converting is a process that guarantees the final product to be of high quality and functional as well as aesthetically appealing. Each process starting from material selection to the final packing is very important in order to provide reliable and quality labels that meet the market requirements.

Essential Equipment Used in Label Converting

A label-converting machine is not a single machine but a converting production specialized system that includes several machines. Every machine is intended for particular steps of the process and all of them together turn raw materials into high-quality labels. These machines cover the printing process right from printing to finishing and they offer accuracy, productivity, and versatility to meet the various needs of the industry. Below are the essential components of a label-converting system and their functions:

| Equipment Type | Main Function | Application Stage |

| Label Printing Machine | Applies design, branding, and product info on the face stock | Initial printing process |

| Die Cutting Machine | Cuts labels into specific shapes and sizes accurately | Label shaping and sizing |

| Slitting and Rewinding Machine | Splits large rolls into smaller rolls for storage and application | Post-processing and storage |

| Label Inspection Machine | Detects printing errors, alignment issues, and adhesive problems | Quality control |

| Laminating Machine | Adds protective films for durability and visual appeal | Ensures durability and aesthetics |

| Coating Machine | Applies gloss, matte, or UV coatings to enhance appearance and functionality | Improves label finish and protection |

| Hot Stamping Machine | Adds foil, embossing, or holograms for luxury labels | High-end packaging and branding |

| Adhesive Application System | Ensures uniform adhesive application on labels | Critical for adhesive consistency |

| Finishing Machine | Performs final trimming, inspection, and packaging | Prepares labels for shipment |

Label Printing Machine

During the initial process of label converting, the printing machine applies the design, branding, and information on the label’s face stock. With distinct demands for production processes come distinct printing methods:

Digital Printing: It is the most ideal option for short runs since its flexibility and easy set-up, less waste. Designed for detail, sharp, and vibrant graphics, digital printing was ideal for small businesses, promotional campaigns or use in variable data printing, for example with serial numbers and QR codes.

Flexographic Printing: This technology is widely useful and economical in the manufacturing of labels on a large scale. It employs the use of flexible plates and works on a wide range of substrates, from paper and plastic to metallic films. Due to its rapid speed and consistent output quality, it has a high level of efficiency in food packaging, logistics, and retail labeling.

Offset Printing: It is the best printing technique for premium packaging since it delivers exceptional details and images. It ensures precise color reproduction, so it is most suitable for larger quantities of prints where color work is intricate, luxury goods, and high-end branding.

Modern printing machines integrate advanced technologies such as color calibration systems, registration control, and substrate compatibility checks. All of these would lay a strong base to ensure that the label-converting processes that follow graphic printing are very accurate and result in sharp and vibrant graphics.

These advancements are taken a notch higher by leading manufacturers such as KETE, who provide printing solutions that are both accurate and fast. KETE is a reliable source for quality printing machines that are ISO 9001, CE, Rand oHS certified and come with a one-year warranty.

If you are interested in increasing your business with modern equipment. Contact KETE now to learn how our sophisticated technologies and dependable services can help you succeed.

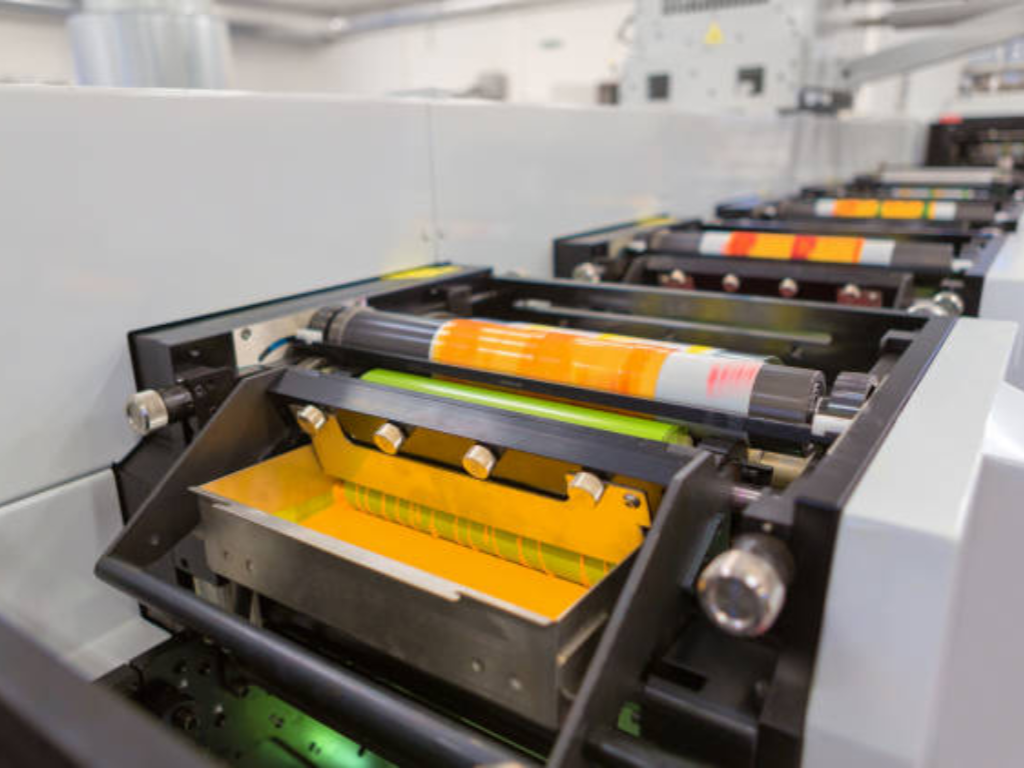

Die Cutting Machine

The die-cutting machines are used in cutting labels into various sizes and shapes to fit the application needed. Two main types of die-cutting machines are commonly used:

Flatbed Die Cutters: These machines are best suited for detailed designs and are most suitable for small-scale production. The stamping motion gives very high accuracy due to its repeatability and is ideal for small numbers of labels to be printed. Though this machine provides some amount of efficiency, the slow speed hampers their usage in areas that require processing for large volumes of data.

Rotary Die Cutters: Rotary die cutters are preferred when the amount of cutting required is extensive because these machines are very fast. They also have a cutting motion that is continuous and permits precision at a high skill level. Rotary die cutters are faster than flatbed machines, and therefore suitable for industries that require high-volume production, such as logistics and packaging industries.

Compared to other conventional die-cutting technologies, rotary die-cutting does have advantages in terms of accuracy reproducibility and economy when applied to large-scale label-converting operations.

Slitting Rewinding Machine

Slitting and rewinding machines are used in the mid to the later stages of the label-converting process. These machines after printing and cutting further slit the large rolls into smaller rolls that can be stored, transported, or applied. For these reasons, these machines require tension control and alignment to be kept constant throughout the production process. This helps avoid problems such as wrinkling, damage at the edges, or uneven rolls.

By integrating seamlessly with earlier stages of production, slitting and rewinding machines guarantee that labels do not shift or become misaligned. This step is critical to provide labels in a format that is usable for the next step of application or further processing to avoid time wastage.

Label Inspection Machine

Label inspection machines are very important in ensuring quality from the time the label is inspected up to the time it is converted. Equipped with advanced cameras and sensors, they detect a wide range of defects including:

Printing problems like wrong alignment of designs or wrong color shades.

Issues that are related to die cutting, such as cases where the cutting is not fully done or where the shape of the cut is not as desired.

Defects in adhesion, such as poor adhesion or lack of adhesion, or uneven application or leakage.

Inspection machines help in detecting errors early, hence reducing wastage, time, and energy used in reworking the labels that are not perfect and only perfect labels are allowed to go to the next level. It is crucial for them to ensure that they deliver quality products that meet the customer needs, and industry standards and increase production capacity.

Laminating Machine

Label laminating machines are very important in increasing the usability of labels. By applying a protective film, they act as a barrier to things like moisture, UV light, scratches, and other general mishandling that labels may undergo. This protection is most needed for labels that will be exposed to harsh conditions such as in the outdoors or in industries.

Other than the durability, laminates also give a touch of aesthetic appeal to a label through a gloss or matt appearance. It helps to guarantee the label’s aesthetic quality does not degrade with time, while also improving the label’s appearance to make it more attractive and credible to end consumers. Laminating is important in the production of labels, especially in ascertaining the functionality and the appearance of the labels.

Hot Stamping Machine

Hot stamping machines are used to give labels a touch of luxury by embossing foil, gold, silver, or hologram onto the label. This process improves both the texture and the appearance or feel of a material thus it is recommended for sectors such as cosmetics, wines, and Champagne and high-end packaging. The coordination of hot stamping machines with other equipment allows the foil designs to blend with printed parts for a perfect finish that is professional.

Coating Machine

Coating machines add value to labels by providing functional or aesthetic layers to the label surface. There are Gloss, Matte, or UV coatings, for example, that not only enhance beauty but also enhance durability, scratch resistance, and resistance to environmental conditions. UV coatings are most necessary for labels exposed to conditions or direct sunlight to have durability and everlasting colors.

This step is crucial in order to sustain the label quality in such demanding sectors as retail or industrial packaging. By seamlessly integrating with other production stages, the coating machine could enable the manufacturing of labels with strict visual and performance specifications while improving accuracy across the converting process.

How to Choose Your Right Label Converting Machine?

Selecting the right label converting machine is not an easy task and one cannot make a haphazard decision without considering some factors. The goal is to achieve the best fit of the machine for your operations while creating sustainable value. Here are the key aspects to evaluate:

Processing Needs

The first step is to determine the kind of labels that are required. Consider the type of labels you print on, such as paper, film, or metalized substrates, and the sizes and shapes of the labels you create. If your process involves several steps such as printing, cutting, and laminating, then consider a machine that has all these features. If your requirements fluctuate often, then machines with a variable setup are the best for you.

Production Efficiency

Ensure that the speed and the capacity of the machine is appropriate for your production needs. In large-scale operations, high-speed machines are mandatory. Small businesses may target machines that allow for fast conversion from one product to another for different customers. Automated features, like tension control and error detection, could reduce the time spent and material used.

Accuracy and Quality Control

Accuracy is necessary to ensure standardization and quality of the labels that are to be created. Avoid machines that do not have alignment features, the cutting tools of the machine, and the integrated inspection to avoid mistakes. They guarantee that your labels meet exact specifications, this is crucial, particularly with industries such as medical ones or logistics, where errors can cause serious issues.

Costs and Budget

Consider the initial cost and long-term expenses. Although the cost of advanced machines may be higher than the basic ones, they are cheaper to maintain and have less time off. Consider energy efficiency, spare parts availability, and the amount of training operators will require to calculate the total cost of ownership (TCO) will assist you in planning.

Compliance with Standards

Select a specific device compatible with some common international standards such as 9001 ISO for quality and RoHS for environmental compliance. Machines that are built to these standards are more reliable and assist in achieving customer and regulatory requirements.

Supplier and Support

Make sure to rationally select a supplier with a reputation. Reliable brands come with even better warranties, spare parts, and most importantly, technical support. Services like following your machine and providing technical solutions based on your needs, such as teaching you how to install, training, and regular maintenance to ensure your machine works smoothly and delivers value over time.

Taking all these factors into account, you will be able to choose the right label-converting machine with regard to its accuracy, speed, and reasonable price. The right choice will help you work faster, produce better results, and prepare your business for the present and future needs.

Materials in Label Converting

The materials employed in label converting are the foundation of quality and effective labels. All three elements of face material, adhesive, and release liner play a part in making sure that the label is fit for the market.

Face Material

The face material is the part of the label that is visible and on which designs and information are printed. It can be made from paper, film, or specialty materials such as metal foil. The choice depends on the application, for example, the labels on cosmetic products may need a glossy finish while the industrial labels may need to be harder-wearing.

Adhesive

Labeling agents hold the label to its surface and may be of different types depending on the use intended. There are permanent adhesives for long-term use for labels that do not need to be removed and removable adhesives for short-term use such as promotional stickers. Repositionable adhesives are useful when the exact positioning of the item is required. In converting, it is important to ensure that the adhesive is applied uniformly to prevent the formation of defects that may affect the label.

Release Liner

The release liner is the backing material that protects the adhesive before application. It is made from silicone-coated paper or film so that the label can be easily peeled off and affixed without leaving any mark. Its quality determines the simplicity and time taken to apply it, especially in automated systems. The release liner can also be poorly designed and this can lead to misalignment or tearing of the liner when applying it.

When properly choosing and combining these materials, it is possible to produce labels that are both practical and aesthetically pleasing for various industries such as cosmetics, food packaging, and logistics.

How to Optimize Efficiency in Label Converting?

Optimizing efficiency in label converting requires a combination of advanced technology, well-maintained equipment, and skilled operators. Here are key strategies to achieve better results:

Upgrade to Advanced Equipment

Replace old machines such as die-cutting machines with automatic ones or use digital printers for faster and more accurate work. These machines do not require much time to be repaired, so they could minimize downtime and they also use little material.

Implement Routine Maintenance

It is recommended to perform regular checks and maintenance of equipment, like rewinders and laminators. Causes maintenance work is important in ensuring that avoids unexpected breakdowns and causes untold damage.

Train Your Team

Make sure your operators comprehend the whole converting process and are capable of operating the equipment. Qualified employees can easily detect problems and prevent them from disrupting the normal running of the business.

Strengthen Quality Control

Integrate label inspection machines could find defects at the initial stages possible. This reduces wastage as well as ensures that various errors don’t advance to subsequent phases resulting in shoddy work.

Through the employment of these approaches, the productivity of the enterprise will increase, costs will be cut, and customer needs and wants will be met with increased effectiveness.

What Are Labels Converting Best Practices?

Adopting the best practices in label converting is a way of ensuring that production is efficient, quality, and sustainable. Here are the key points to success:

Use High-Quality Materials

The highest quality face material, adhesive, and release liner are the basis for the formation of quality as well as reliable labels. Choose materials according to the needs of the industry like food contact, water resistance, or heat resistance to meet the application needs.

Standardized Operating Procedures

Create documented workflows of the entire process starting from material choice to other processes such as printing, die cutting, and rewinding. Need to introduce quality control practices and support operators by offering training on how to implement them.

Invest in Advanced Technology

Keep adopting better technology that includes the use of digital printers, use of the automated die cutters, and the use of intelligent inspection systems to enhance precision. The integrating implementation of production management systems provides a mechanism for coordinating the system in real time hence increasing productivity.

Focus on Waste Reduction

Improve the position of labels and increase equipment precision to reduce material usage. Learn about the concept of recycling and reusing excess materials to reduce costs and achieve sustainability objectives.

Stay Informed

It is crucial to go to industry meetings or training to enhance awareness of emerging trends like; Environmentally friendly substrates, new types of adhesives, or the digital printing kind. Customers’ feedback should be used to determine the changes in the market and how they can be used to alter production strategies.

The above best practices will help the label-converting businesses to provide quality products that meet the market and environmental needs to gain a competitive edge.

Troubleshooting Label Converting Problems

There are several problems that may arise during label converting processes, but if they are solved as soon as possible, the processes will be effective and high-quality. Here are common problems and their solutions:

Printing Issues

Inaccurate alignment or registration is usually caused by a problem with the machine settings. Check that the label printing machine is set up right, feed settings are correct and the substrate is aligned properly. It is also important to check rollers and printheads for signs of wear in order to maintain print quality.

Adhesive Failures

Adhesion problems may arise from the use of the wrong adhesive or adhesive that has been influenced by some conditions such as temperature or humidity. Ensure that the adhesive properties of the label (permanent or removable) correspond to the use of the label and check storage conditions to avoid failures.

Die Cutting Errors

Inaccurate shapes or cuts are usually as a result of worn cutting dies or improper alignment. Check the dies for sharpness and also check the tension of the die-cutting machine. Maintenance reduces the chances of making mistakes and also reduces wastage.

Inspection Failures

Print defects or uneven cuts in the finished labels can be reduced by conducting regular inspections at some critical points in the production line. Label inspection machines should be used wisely to detect problems at an early stage so that material wastage and poor quality can be avoided.

If these challenges are tackled systematically, then companies will be able to minimize production downtimes, and increase productivity and quality.

Conclusion

Label converting is a complex process that involves the use of sophisticated machinery, accurate materials, and unique approaches to provide quality custom labels. Each process, from label printing to die cutting, coating, and inspection, is a critical process that must be done right. Adhering to the best practices and increasing the efficiency of the labeling process, companies can guarantee the compliance of their labels with the requirements of the market and at the same time remain competitive.

Whether you are designing labels for your products, using barcodes for tracking, or using metal foil stamping for a touch of luxury, it is important to understand the label-converting process. If you have the right tools, materials, and methods, you can be precise, durable and get the best results.