Aujourd'hui, dans toute entreprise, l'efficacité est toujours prioritaire. Considérons la chaîne de production d'une usine comme une rivière où les matières premières se déplacent continuellement en aval. Chaque étape de production sur la ligne s'apparente à une "porte" où les matériaux ne sont pas simplement poussés, mais coupés, modifiés et réorganisés d'une manière hiérarchiquement structurée qui leur permet d'être acheminés vers d'autres processus de travail. Parmi tous les dispositifs de refente et d'enroulement, les refendeuses à tourelle, également connues sous le nom d'enrouleuses à tourelle ou d'enrouleuses automatiques à tourelle, sont les plus appréciées en raison de leur conception et de la manière dont elles augmentent la productivité de l'entreprise. Elles automatisent les étapes finales de la production, ce qui se traduit par une production plus rapide et une meilleure productivité globale.

Qu'est-ce qu'une bobineuse découpeuse à tourelle ?

Comme son nom l'indique, une refendeuse-enrouleuse à tourelle est une machine sophistiquée utilisée pour le processus de refente et d'enroulement en continu et à grande vitesse de matériaux présentés sous forme de rouleaux. La principale caractéristique de ce type de machine est la structure de la "tourelle", qui est montée sur la broche et tourne autour d'un axe central. Elle comporte généralement deux arbres d'enroulement ou plus. Contrairement aux bobineuses traditionnelles à simple ou double bobine qui interrompent en permanence leur fonctionnement pour décharger une bobine pleine et charger un nouveau mandrin, la conception de la tourelle permet de commuter les arbres d'enroulement sans relâchement par la rotation de la tourelle avec une faible vitesse ou une décélération statique. On obtient ainsi une production ininterrompue.

Comment fonctionne le système de tourelles ?

Le fonctionnement efficace d'un système à tourelle repose sur une séquence continue de processus automatisés. Lorsque la machine détecte que l'arbre de rembobinage en cours est sur le point d'atteindre la longueur ou le diamètre prédéfini, la séquence d'automatisation est déclenchée. Tout d'abord, un mécanisme de coupe précis effectue une coupe transversale du matériau à grande vitesse. Ensuite, le bord d'attaque du nouveau matériau est automatiquement guidé et fixé à un mandrin vide placé de l'autre côté de la tourelle, généralement à l'aide d'un applicateur de ruban automatique (lié au chargement automatique des mandrins). Ensuite, la tourelle pivote rapidement de 180 degrés (pour un système à deux tourelles), amenant l'arbre avec le nouveau mandrin en position d'enroulement tout en déplaçant la bobine complète hors de la zone de travail. Ces rouleaux terminés peuvent être déchargés en toute sécurité par l'opérateur pendant que la machine continue de fonctionner, et de nouveaux mandrins peuvent être chargés (cette action comprend souvent le chargement automatique des mandrins) en préparation du prochain changement. L'ensemble du processus est coordonné avec précision, comme un passage de témoin parfait dans une course de relais, avec une précision de l'ordre de la milliseconde, ce qui minimise les temps d'arrêt non productifs et assure un flux de production régulier.

Pourquoi les transformateurs devraient-ils investir dans une bobineuse-découpeuse à tourelle ?

Pour les transformateurs qui se concentrent sur la production de gros volumes de substrats en rouleaux, l'adoption de découpeuses à tourelle est un investissement majeur pour améliorer la compétitivité. Il ne s'agit pas seulement d'un gain de vitesse, mais aussi d'un changement complet du modèle de production. Les avantages de la technologie de la tourelle sont particulièrement évidents.

Le gain le plus immédiat est de loin celui de l'efficacité de la production et du débit relatif. La réduction des temps morts consacrés à la rotation des bobines augmente considérablement le rapport entre la production traitée et le temps lorsque l'on travaille avec un grand nombre de bobines de petit diamètre et de faible volume, comme c'est souvent le cas pour les travaux de courte durée. Pour de telles applications, une bobineuse-découpeuse à tourelle est souvent la solution idéale.

En outre, elle contribue à optimiser la structure des coûts opérationnels. Une plus grande efficacité permet d'atteindre des chiffres de production plus élevés dans un délai donné, ce qui, à son tour, réduit la main-d'œuvre et l'énergie consacrées à d'autres flux sans valeur ajoutée. En outre, les systèmes automatisés diminuent le besoin d'opérateurs qualifiés, ce qui réduit les erreurs et le gaspillage de matériaux.

En outre, bien que nous disposions de systèmes avancés de contrôle de la tension et de guidage de la bande pour un déroulement rationalisé sans jeu, un tranchage robuste et un rembobinage précis, les machines à tourelle améliorées avec précision tendent à faire mieux. Il en résulte des rouleaux à profil plat bien homogènes qui sont enroulés en continu sans formation de marches et sans bords bruts. Les attentes des clients sont ainsi toujours satisfaites et même dépassées. Une qualité fiable renforce la fidélité des clients tout en protégeant et en améliorant l'image de marque.

Enfin, l'achat d'une bobineuse-découpeuse à tourelle accroît la flexibilité de la production. Elle permet une plus grande variété et une plus grande fréquence de changement des matériaux, ce qui permet à l'entreprise de répondre plus rapidement aux évolutions du marché et aux demandes personnalisées.

Quels matériaux peuvent être traités ?

Les bobineuses découpeuses à tourelle présentent une excellente compatibilité avec les matériaux et peuvent traiter de manière stable et efficace une grande variété de matériaux de bande flexibles, y compris les plus courants :

- Divers films plastiques (par exemple, BOPP, PET, CPP, PE, PVC utilisés pour l'emballage, l'agriculture ou l'industrie)

- Papier et carton

- Stratifiés (par exemple, stratifiés papier-plastique, film-plastique)

- Tissus non tissés

- Feuilles métalliques (par exemple, feuilles d'aluminium)

- Différents types de rubans auto-adhésifs et de rubans industriels

- Divers matériaux pour étiquettes en rouleau

- Certains textiles spéciaux

Des matériaux différents nécessitent des configurations de machines et des conditions de fonctionnement différentes. Par exemple, la manipulation de films fins nécessite un contrôle plus précis de la tension, associé à des mesures antistatiques. À l'inverse, le papier plus épais ou les matériaux rigides peuvent nécessiter des forces de coupe plus élevées avec des angles de couteau différents. Des solutions personnalisées adaptées aux matériaux principaux du client sont proposées par des spécialistes compétents.

Industries et applications de la rebobineuse à tourelle

Les bobineuses découpeuses à tourelle sont des équipements indispensables dans de nombreuses industries qui dépendent du traitement des matériaux en bande, et leurs applications sont très répandues :

- Industrie de l'emballage : Production de divers rouleaux de films d'emballage souples et de rouleaux de laminés pour les lignes d'emballage automatisées dans les secteurs de l'alimentation, des boissons, de la chimie quotidienne, de la pharmacie et d'autres industries.

- Impression et transformation d'étiquettes : Il s'agit souvent d'une intégration avec des processus tels que la découpe à l'emporte-pièce, à l'aide d'un emporte-pièce ou d'une découpeuse à l'emporte-pièce, avant de découper divers matériaux d'étiquetage en papier et en film en rouleaux pour les machines d'étiquetage.

- Fabrication de rubans : Refendre des rouleaux de bande large en rouleaux finis de la largeur souhaitée.

- Transformation de produits en papier : Découpe de papier spécial, de papier d'essuyage, de papier peint, etc., pour utilisation dans l'imprimerie, la construction, l'industrie et d'autres domaines.

- L'industrie des nouvelles énergies : Refendre et enrouler avec précision des matériaux tels que des séparateurs et des collecteurs de courant dans la fabrication de batteries au lithium et de films photovoltaïques.

- Industrie des produits d'hygiène : Refendage de tissus non tissés et d'autres matériaux.

On peut dire que la découpeuse-enrouleuse à tourelle sert de "voie rapide" dans le processus de production industrielle lorsque de grandes et larges bobines de matériau doivent être réduites en bobines plus petites et plus étroites et qu'une grande efficacité est requise.

Sélection de l'enrouleur-scissionneur à tourelle adéquat

Une évaluation approfondie est essentielle pour choisir une bobineuse-découpeuse à tourelle qui répondra constamment aux exigences de votre activité pendant de nombreuses années :

Définir vos besoins de production

Commencez par examiner vos scénarios de production actuels et futurs : Quelles sont les principales catégories de produits que vous traitez ? Quelles sont vos prévisions de ventes et de croissance de la production ? Précisez les propriétés des matières premières telles que la largeur, l'épaisseur, l'allongement, etc. La qualité de la vision du rouleau de finition rationalisé et le degré d'automatisation visé sont également notés. La définition précise de vos critères vous aidera à atteindre vos objectifs.

Évaluer les principales spécifications

Évaluez les principales caractéristiques techniques de la machine pour voir si elles répondent à vos besoins. Vérifiez si la largeur de travail maximale et la vitesse mécanique répondent à vos attentes en matière de débit. Vérifiez également si les diamètres maximum de déroulement et d'enroulement correspondent à la taille de vos bobines. La largeur de refendage minimale est-elle conforme aux exigences de votre produit ? Le système de contrôle de la tension permet-il de gérer vos matériaux de manière fiable ? La méthode de refendage (cisaillement, rasoir, écrasement) est-elle adaptée à vos matériaux et à vos étapes de traitement ? Lors de l'évaluation des capacités, il est essentiel de prendre en compte des facteurs tels que les largeurs de bande maximales.

Évaluer l'automatisation nécessaire

Les différentes machines à tourelle ont des niveaux d'automatisation variables. Outre les fonctions automatiques de base que sont le changement de bobine, la coupe et le collage, quelles sont les autres fonctionnalités nécessaires ? Le positionnement des mandrins, le déchargement des rouleaux finis, le positionnement des couteaux et les systèmes d'inspection en ligne sont des exemples d'automatisation supplémentaire. Comme pour la plupart des machines, un accroissement de l'automatisation entraînera un investissement initial plus important. Toutefois, l'automatisation peut apporter des avantages bien plus importants à long terme. Tenez compte de votre budget et de l'urgence d'améliorer l'efficacité tout en évaluant le niveau d'automatisation souhaité.

Considérer le fabricant et l'assistance

Il est essentiel de sélectionner un fabricant fiable et digne de confiance. Examinez son expérience dans le secteur, ses capacités techniques, ses procédés de fabrication et ses systèmes de contrôle de la qualité. Parallèlement, les processus couvrant la consultation avant-vente, la conception de la machine, l'installation de l'équipement, la mise en service, la formation à l'exploitation et à la maintenance, ainsi qu'un service après-vente et un approvisionnement en pièces détachées cohérents et fiables, contribuent à garantir que la machine fonctionne de manière efficace et optimale.

Maintenance et dépannage

Une découpeuse-enrouleuse à tourelle, étant une machine de précision, nécessite un entretien régulier et systématique. Cela implique les efforts combinés des opérateurs et du personnel de maintenance. Un entretien opportun est essentiel pour le fonctionnement optimal d'une bobineuse-découpeuse à tourelle sur de longues périodes. Un mauvais entretien, voire l'absence d'entretien, peut endommager l'équipement, réduire sa durée de vie et même entraîner des arrêts de production ainsi que des réparations coûteuses. Pour nos clients, voici quelques conseils de maintenance et de dépannage que vous pouvez appliquer :

Contrôles et nettoyages quotidiens (par équipe) :

- Nettoyage des surfaces : Débarrasser soigneusement la machine et les revêtements de nettoyage de toute poussière, restes de matériaux ou étiquettes. Il convient d'éviter tout excès d'humidité dans les composants électriques.

- Nettoyage de la zone de travail : Les rognures, le matériel excessif et l'adhésif doivent être immédiatement éliminés des espaces de découpe et d'enroulement, et les couteaux et les rouleaux de renvoi doivent également être nettoyés.

- Vérification du galet tendeur : Vérifier que chaque rouleau est dégagé et qu'il tourne sans être entravé par des matériaux ou des adhésifs susceptibles de provoquer un frottement.

- Contrôle de la pression d'air : Vérifier que la pression d'alimentation en air primaire se situe dans les limites opérationnelles de la machine et s'assurer que l'unité de préparation de l'air (filtre, régulateur, lubrificateur) fonctionne correctement et que la vanne de vidange est fonctionnelle (si nécessaire).

- Contrôle de sécurité : Vérifier le fonctionnement des boutons d'arrêt d'urgence, de l'interrupteur de la barrière de sécurité, des barrières immatérielles et de tous les autres dispositifs de sécurité essentiels.

Hebdomadaire Maintenance Tâches :

- Points de lubrification : En suivant le tableau de lubrification du fabricant, appliquer les lubrifiants sur tous les points à lubrifier (par exemple : roulements, guides linéaires, chaînes, etc.) Ne pas appliquer de lubrifiants en excès.

- Vérification des composants de l'entraînement : Vérifier la tension des courroies et des chaînes pour s'assurer qu'elles sont bien tendues et qu'elles s'usent. Vérifiez également le niveau d'huile dans les boîtes de vitesses, le cas échéant.

- Vérification et nettoyage des couteaux : Examinez les surfaces (circulaires et rasoir) des couteaux de coupe pour vérifier qu'ils sont bien aiguisés, qu'ils ne présentent pas d'entailles et qu'il n'y a pas d'accumulation d'adhésif. Nettoyez-les ou remplacez-les si nécessaire.

- Contrôle pneumatique de la ligne : Vérifier que tous les tuyaux d'air ne vieillissent pas, ne durcissent pas et ne sont pas endommagés. S'assurer que tous les raccords sont bien serrés et ne fuient pas...

Périodique Maintenance (mensuel/trimestriel/annuel) :

- Vérification de la connexion électrique : (Doit être effectué par un électricien qualifié) Assurez-vous que toutes les connexions des bornes à l'intérieur et à l'extérieur de l'armoire de commande sont sûres et qu'aucun câble n'est endommagé. Les composants électriques doivent être exempts de poussière.

- Capteur et Actionneur Vérifier : Vérifier le bon fonctionnement et la précision dans les limites admissibles des capteurs (photoélectriques, de proximité, de tension) et des actionneurs (servomoteurs, vérins).

- Vérification des roulements : Vérifier l'absence de bruit anormal ou de chaleur excessive au niveau des roulements. Remplacer si nécessaire.

- Air Contrôle de l'arbre : Vérifier que les clavettes ou les pattes ne sont pas endommagées ou trop usées. Confirmer le bon fonctionnement des arbres à air de gonflage et de dégonflage.

- Étalonnage du système : Calibrer régulièrement les composants de contrôle, y compris le système de contrôle de la tension, le système de guidage de la bande et le compteur de longueur.

- Sauvegarde du logiciel : Effectuer des sauvegardes des programmes et des paramètres de la séquence de contrôle pour la machine concernée.

Dépannage courant (niveau opérateur) :

- Enjeu : La forme finale du rouleau est "conique" ou "bombée".

- Causes possibles : Mauvais réglage de la tension, variations de l'épaisseur du matériau, problèmes de mandrin, pression du rouleau de coupe, problèmes d'arbre de déroulement.

- Premières étapes : Changement de tension pour le rembobinage, évaluation de l'intégrité du noyau, examen de la bobine de matériau, évaluation de la pression du rouleau nip, nettoyage des arbres liés au rembobinage et vérification du gonflage ou changement de tension.

- Enjeu : Les bords du matériau de fente sont rugueux ou présentent des bandes fusionnées.

- Causes possibles : Lames émoussées ou mal alignées et ajustées, pression insuffisante exercée par les couteaux, incohérences dans les matières premières, sélection incorrecte de la méthode de découpe.

- Premières étapes : Nettoyer ou remplacer les couteaux, améliorer le chevauchement des couteaux en fonction de la pression exercée, vérifier les incohérences du matériau.

- Enjeu : Le changement automatique de rouleau ne parvient pas à fixer le matériau sur le nouveau noyau.

- Causes possibles : Ruban épuisé ou applicateur de ruban défectueux, mauvaise position pour l'application du ruban, défaut de la surface de l'âme, coupe non symétrique du matériau, pression d'air trop faible.

- Premières étapes : Remplacer le ruban et vérifier le mouvement des applicateurs, vérifier la surface du noyau, ajuster la position pour la coupe ou vérifier les couteaux.

L'entretien préventif de routine d'une bobineuse-coupeuse est la "bouée de sauvetage" qui garantit la fiabilité durable du fonctionnement d'une bobineuse-coupeuse à tourelle.

Partenariat avec un expert en machines à découper

Un partenaire fiable est comparable à un guide expérimenté qui vous aide à naviguer en toute sécurité sur des eaux sinueuses. Avec de tels fournisseurs d'équipement, il manque une assistance appropriée pour fournir un soutien complet et une valeur tout au long de la durée de vie de la machine.

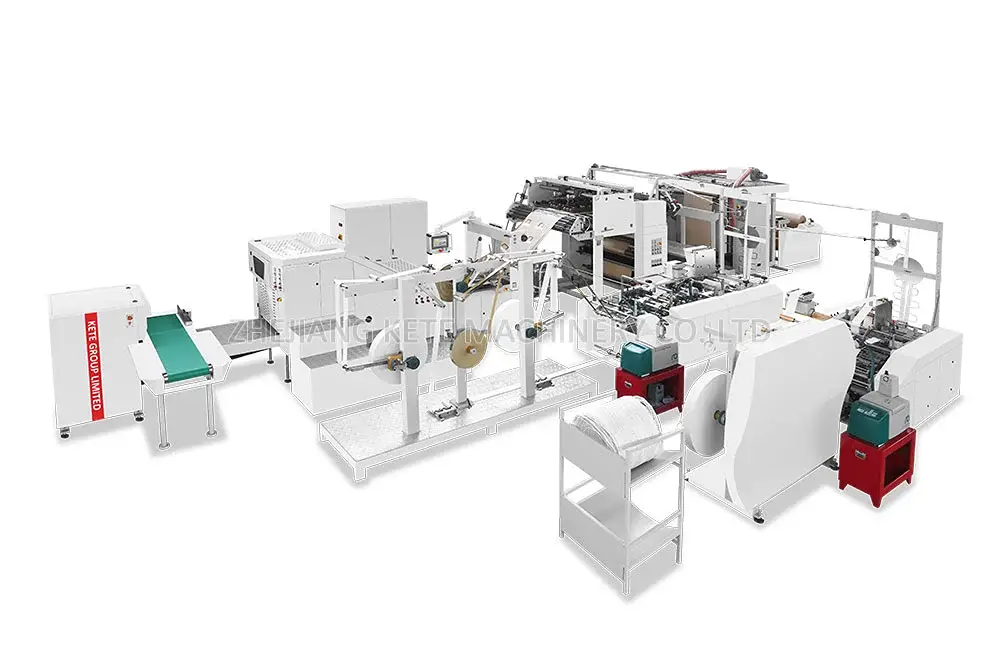

C'est là que des entreprises comme KETE se distinguent. KETE propose une gamme de bobineuses découpeuses à tourelle de haute performance et de haute qualité, y compris des modèles avancés tels que la série KTSM-C600T, conçue pour une production rapide et efficace. Grâce à l'expérience de plus de 30 ans de l'équipe principale et à l'héritage de la fabrication depuis 1983, KETE a une connaissance approfondie de l'industrie. Son équipement est soutenu par des certifications strictes d'assurance qualité (ISO 9001, CE, RoHS) qui garantissent une fiabilité globale. KETE est présent dans plus de 80 pays et possède une vaste expérience du commerce international, ce qui garantit une expédition fiable et une assistance mondiale. KETE propose des options personnalisées spécifiques ainsi que des services de conseil complets, des rapports d'avancement honnêtes, des livraisons groupées et des services après-vente complets, y compris des garanties et des formations. KETE ne se contente pas de fournir des machines de pointe, mais offre également des conseils d'experts inébranlables pour que ses clients se sentent toujours à l'aise.

Conclusion

En raison de sa capacité de production continue, la bobineuse-découpeuse à tourelle est l'un des outils modernes les plus puissants pour améliorer l'efficacité et la capacité de transformation des matériaux en bande. Pour tirer le meilleur parti de la machine, il faut se familiariser avec sa conception et sa fonctionnalité, ses applications, ses procédures d'exploitation et de maintenance, son entretien intensif et ses procédures de maintenance. En outre, le fait d'avoir un partenaire comme KETE, qui a une grande expérience, qui est renommé dans le domaine, qui a des compétences techniques fiables, une excellente infrastructure et un système de secours complet, garantit que l'investissement réalisé sera protégé et maintenu pendant de nombreuses années. Ici, il ne s'agit pas seulement de la productivité d'une machine, mais de l'ensemble de l'écosystème de fabrication et de la résilience de votre entreprise.