What Exactly Are Flexographic Printing Plates?

Flexographic printing plates are the most crucial components of the flexographic printing process since they are the image carriers that transfer ink to the substrate. These are usually made of photopolymer, rubber or elastomeric material and have a raised image on the surface. Ink is applied to the surface of the material and only the elevated portions of the image come into contact with the substrate to produce the print. This method is particularly famous for its ability to print on various types of materials such as paper and cardboard, plastics, and films, which makes it a staple in the packaging and labeling sector.

Why the Right Plate Choice Matters for Print Quality

Choosing the right flexographic printing plate is not a small decision; it defines the quality of the final product and its uniformity. Just as a sculptor carefully selects the tools for carving, a printer has to choose the plate that will be suitable for the specific design and the material to be printed on. An ill-suited plate can cause a range of issues such as low image quality, mottle or voids due to uneven ink transfer, and even damage to the substrate. On the other hand, the correct plate provides sharp image details, bright colors and a professional look and feel, which is in line with the brand’s quality assurance.

Moreover, the right choice of the plate affects the productivity and cost of the printing process in equal measure. A long-lasting and compatible plate will be able to handle more prints before it wears out, thus, less time is spent on changing the plates and less material is wasted. Given the vast array of substrates and inks currently on the market, it is crucial to comprehend the peculiarities of different types of plates and their compatibility with these factors to attain the best results in terms of print quality and productivity. In its simplest terms, the plate is the link between the design concept and the physical printed product.

Types of Flexographic Printing Plates

Photopolymer Flexographic Printing Plates

Photopolymer flexographic printing plates, which are the most popular type of flexographic printing plates in the contemporary world, are made of synthetic polymers that have a unique photosensitivity. These are usually in sheet form and are exposed to ultraviolet light to harden the areas that are equivalent to the non-printing parts of the design. The areas that are not exposed dissolve and are washed off, while the raised areas of the image remain intact. Photopolymer plates are highly valued for their capacity to provide high resolution prints and fine details, which is suitable for designs with complex details and high quality images. They also support a broad range of ink types such as water-based, solvent-based, and UV-curable inks. However, photopolymer plates are slightly more sensitive to some solvents or may have some issues in very long runs compared to some rubber types while providing excellent image quality and durability for many applications.

Rubber Flexographic Printing Plates

Rubber flexographic printing plates can be considered as more traditional, but they are still widely used in certain types of printing. These plates are usually produced from natural or synthetic rubber materials and may be vulcanized to the required hardness and elasticity. Rubber plates are generally made through a molding process in which a matrix or die is used to produce the raised image on the rubber surface. Rubber plates are very durable and long-wearing, especially in high-volume runs and with abrasive inks. Their inherent resilience also makes them well-suited for printing on rough or uneven surfaces, such as corrugated cardboard. Although photopolymer plates may provide a higher level of detail than rubber plates, the technology of rubber plates is also being developed and enhanced to provide better image reproduction for packaging and industrial printing.

Elastomeric Flexographic Printing Plates

Elastomeric flexographic printing plates are intermediate between photopolymer and conventional rubber plates and possess some characteristics of both. These plates are made from synthetic elastomers and are generally flexible, durable and have the ability to reproduce images. The production of elastomeric plates can be different, and the relief image can be made by direct laser ablation or other methods. One of the major benefits of some elastomeric plates is that they are suitable for good ink transfer and can work with a variety of inks and substrates. They also show good resistance to swelling and distortion which makes the prints to be of good quality for a long time. Although the term elastomeric can be used to describe a wide variety of materials with different specific characteristics, these plates are designed to offer a high level of durability and flexibility for printers who may require a combination of properties that are not offered by photopolymer or rubber plates.

The Intricate Process of Making Flexographic Printing Plates

Digital Flexographic Printing Plates

The advancement in digital technology has greatly impacted the production of flexographic printing plates in terms of accuracy, speed and flexibility.

The process of making plates digitally usually starts with a digital image file. This file is then taken through a RIP (Raster Image Processor) software to prepare it for imaging on the plate. One of the most important steps in this process is the making of a digital mask that regulates the exposure of the photopolymer plate. In one of the methods, a layer of black material on the surface of the plate is removed using a laser imaging tool. This area is ablated and serves as a mask that lets UV light through to selectively solidify the photopolymer layer during the exposure step.

Another digital method is laser engraving of an elastomeric plate material directly. After that, the unhardened areas are washed off using a solvent solution to expose the raised image on the photopolymer plates.

Digital plate-making has several advantages: it is possible to achieve high detail and sharpness of the edges of the plate, better register, and variable data printing. The absence of film negatives also helps to save time and minimize the possibility of mistakes.

Conventional Flexographic Printing Plates

However, conventional flexographic plate-making is still a viable method of flexographic plate production for some applications. The conventional process usually involves the production of a film negative of the intended picture. This negative is then put in contact with a sheet of photopolymer material that has not been exposed to light yet. The assembly is then exposed to ultraviolet light. The dark regions of the film negative do not allow the UV light to pass through and therefore the photopolymer does not harden while the transparent regions allow the light to pass through and solidify the polymer. After exposure, the film negative is taken out and the plate is developed in a washout unit. Here, a solvent solution is used to wash and dissolve the unhardened photopolymer and the raised relief image is left behind. The plate is then washed, dried and may be subjected to further processing to enhance its printing properties.

Although conventional plate making may be cheaper in some cases, it is a more time-consuming process and is more sensitive to errors that may occur in the film negative. It may also have limitations in reproducing small details as compared to the digital techniques.

Critical Factors to Consider When Selecting Your Flexo Plate

Substrate Compatibility: Matching Plates to Printing Surfaces

When choosing a flexographic printing plate, it is always important to consider the type of substrate that the ink is to be applied on. Substrates also have different surface properties like roughness, porosity, and flexibility, and these factors affect the ink transfer and print quality. For example, printing on smooth and non-porous substrates such as plastic films may need plates with a smoother surface and possibly different durometers from those used for printing on corrugated cardboard. The contact of the plate with the substrate is very important in order to achieve an even distribution of ink on the substrate. Soft plates may be better for rough surfaces, while hard ones may be better for fine details on smooth surfaces.

Ink Compatibility: Ensuring Proper Ink Transfer

Another factor that needs to be taken into consideration is the chemical compatibility of the material used in the flexographic printing plate and the ink to be used. It is important to note that the various types of inks such as water-based, solvent-based, and UV-curable inks may have different impacts on the plate materials. For instance, some solvents can cause certain types of plates to swell or even deteriorate, which results in distortion and poor quality prints. On the other hand, selecting a plate material that is compatible with the ink chemistry used in the process will guarantee a good transfer of ink, protect the plate from damage and increase its durability. Other factors like viscosity and surface tension of the ink also affect its ability to stick to the plate surface and come off the surface of the plate. Ink compatibility should be given a lot of attention to avoid problems such as ink bleed, poor ink coverage and early failure of the plates.

Print Resolution and Detail Requirements

The amount of detail and resolution needed for a specific print job will determine the type of flexographic printing plate to be used. Digital plates are usually of higher resolution and can reproduce small details, small fonts and halftone images better than analog plates. Although conventional plates can also give satisfactory results, they may not be as effective in providing the ultra-fine details. Another factor that has to be taken into consideration is the line screen or the number of lines per inch (LPI) of the artwork in relation to the capability of the plate. Choosing a plate with the right durometer (hardness) and surface roughness will help to get the right print quality and definition. In high-definition printing, photopolymer plates with certain imaging properties are usually used.

Durability and Longevity for Your Print Runs

The length of the print run is expected to be another important consideration when choosing the right flexographic printing plate. In very long runs, it may be cheaper to use plates made of some types of rubber because they do not wear out as quickly as one might expect. Other factors that may affect the wear of the plate include the pressure applied by the printing press and the roughness of the ink. In general, photopolymer plates are quite durable for most uses, but the type of polymer and the thickness of the plate can affect its life span. Selecting a plate that can handle the load of the print job will reduce the time taken to change the plates and guarantee a consistent quality of the prints throughout the run.

The Synergistic Relationship Between Plates and Printing Machines

The flexographic printing plate is not an independent entity; its efficiency depends on the characteristics and configuration of the printing press. The thickness of the plate and the mounting system should be compatible with the press cylinders for the press to work efficiently. The pressure settings of the press, the condition of the anilox rolls which meter the ink and the overall alignment of the printing units are some of the key factors that determine the quality of the prints. It is crucial to choose a plate that fits the press’s requirements and to make sure that the machine is set up and maintained correctly. It is therefore important to understand that even the best quality of plate will not give the best result on a bad press or on a press that has been set up wrongly. Hence, it is imperative to look at the whole printing system when selecting a flexographic printing plate.

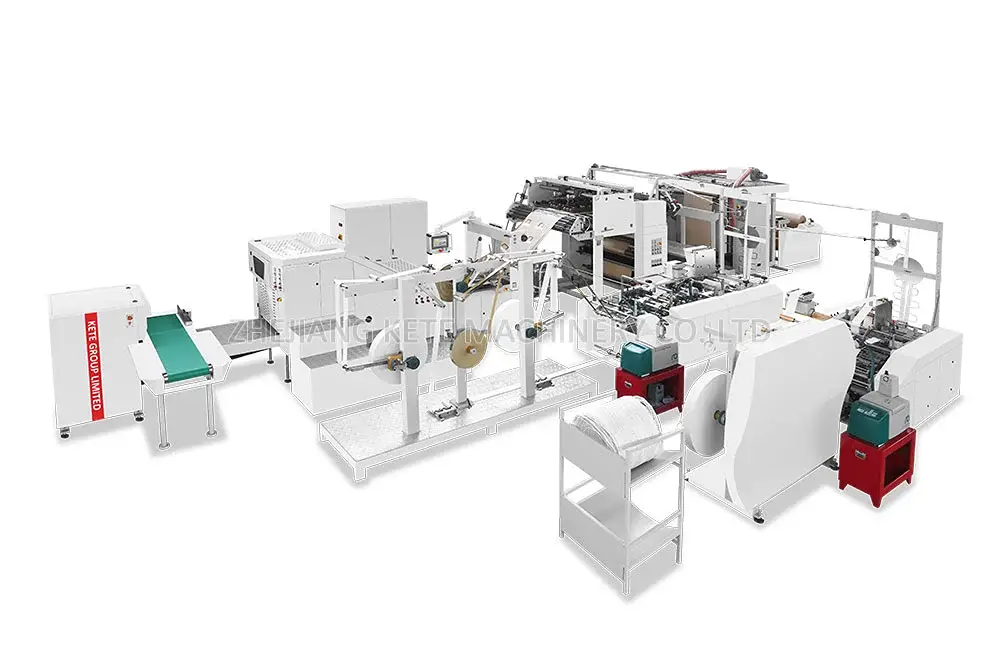

Achieving Superior Flexo Printing with Quality Machines by KETE

KETE, a reputable manufacturer of flexographic printing machinery, understands the critical interplay between high-quality printing plates and the performance of our machines. Our flexographic presses are designed to work in conjunction with different types of plates to provide the best quality prints in a wide variety of applications. In addition, our focus on automation helps to reduce the time required for printing and also eliminates the possibility of human error, which is especially important when using high-quality flexographic printing plates. KETE machines whether stack-type, CI or inline presses are designed to complement the selected plates to ensure high print quality and productivity.

This is complemented by ISO 9001, CE, and Rohs certifications, as well as a quality control system that involves four machine work tests before mass production. Also, KETE supports our machinery with a 2-year warranty to ensure that our flexographic printing presses are long-lasting and dependable. Through the incorporation of these features and the use of sturdy construction, KETE machines offer a stable, accurate, and efficient working environment that enables the user to harness the full potential of high-quality flexographic printing plates to produce excellent and consistent prints.

Contactar-nos:

- Endereço: 20th Floor, Xinchao Building, Anyang Street, Ruian City, Wenzhou City, Província de Zhejiang, China 325200

- Telefone: +86-577-66873227 / 66689036 / 66689037

- WhatsApp / WeChat: +86-18806770163

- Correio eletrónico: sales@ketegroup.com

Flexographic Printing Plates For Different Application Areas

Due to the flexibility of the flexographic printing method, it has been applied in many industries that have different demands. Therefore, the choice of the most suitable flexographic printing plate is not always a simple one. The type of substrate that is to be printed on, the type of ink that is to be used, the level of detail required in the final print and the expected life span of the printed material are some of the factors that determine the most appropriate plate type for a particular job. To give a clear picture of this diversity and to help the reader to get a clear idea about the practical use of flexographic printing and the type of plate that should be used for a particular application, the following table has been prepared:

| Application Area | Suitable Plate Types | Considerações fundamentais |

| Embalagens flexíveis | Photopolymer, Elastomeric | High print resolution for branding, good ink transfer for various films, durability for long runs, compatibility with food-grade inks. |

| Labels | Photopolymer | Fine detail reproduction for barcodes and small text, compatibility with various label stocks (paper, film), resistance to label adhesives. |

| Corrugated Packaging | Rubber, Photopolymer (depending on detail needs) | Durability for abrasive surfaces, good ink coverage on uneven surfaces, cost-effectiveness for large volumes. |

| Newspapers | Rubber | High-speed printing, cost-effectiveness for large print runs, good ink transfer on newsprint. |

| Caixas de cartão dobráveis | Photopolymer | Good print resolution for graphics and product information, compatibility with various paperboard thicknesses. |

| Beverage Cartons | Photopolymer | High print quality for branding, resistance to moisture and scuffing, compatibility with specialized coatings. |

| Envelopes | Rubber, Photopolymer | Flexibility to accommodate varying paper weights and thicknesses, good ink adhesion. |

| Pre-printed Linerboard | Rubber | Durability for high-speed printing, good ink coverage on kraft paper. |

| Textile Printing | Rubber, Elastomeric | Flexibility and durability for printing on fabric, compatibility with textile inks. |

| Wallpaper | Rubber, Elastomeric | Ability to print on textured surfaces, durability for repeated handling. |

Best Practices for Maintaining and Storing Flexographic Printing Plates

Proper Cleaning Procedures for Extended Plate Life

Cleaning flexographic printing plates is very important in order to ensure that the plates last long and produce quality prints. After the print run, it is also important to ensure that there is no ink left on the surface of the plate. The specific cleaning solution to be used will depend on the type of ink that is water based, solvent based or UV curable and the type of plate material. The cleaning agents used should not cause the plate to swell, crack or in any other way become damaged. Wash the plate surface with a soft brush or cloth, especially in the intricate areas of the plate and make sure that all the ink is washed off the image areas. Do not use any abrasive material that may scratch or harm the plate in any way. After washing, the plate should be washed with clean water (depending on the cleaning solution used) and then wiped with a lint-free cloth or placed in a plate drying rack. Cleaning after each use will help to avoid ink accumulation on the plates, which will result in low quality prints and plate wear.

Optimal Storage Conditions to Prevent Damage

The storage of flexographic printing plates is also crucial in maintaining the quality of the plates and the quality of the prints that they will produce. Plates should be stored in a clean and dry area with low temperature and humidity to prevent any form of contamination. High temperatures and humidity can make the plate material rigid, deform or even crack. Ideally, plates should be stored flat, either in their original sleeves or in a plate storage rack that is designed for this purpose. It is also important not to place one plate directly on top of another without using a spacer in between as this may cause scratching or deformation of the image areas. Avoid exposing plates to direct sunlight and UV light as this will make the photopolymer material to become rigid and brittle and cannot be used. For rubber plates, it is necessary to exclude the influence of ozone as it accelerates the deterioration of the material. Storing the flexographic printing plates in the right conditions will go a long way in increasing the life span of the plates and also ensure that they are in the right condition when required for use, with the same quality as when new.

Conclusão

In the context of flexographic printing, the printing plate can be considered as one of the most crucial components, a piece of work that is created with a lot of care and precision and serves as a link between the design and the final product. It is crucial to comprehend the peculiarities of different plates, their production, and the factors that determine their choice to obtain the best outcomes. The interaction between the chosen plate and the printing machine, which is described by the capabilities of KETE’s equipment, also emphasizes the need for an integrated approach to the printing process. Understanding the compatibility of the substrate and ink, the resolution needed for the print, the durability that is required, and the relationship between the flexographic printing and the printing press will help businesses to make the right decisions that will lead to better flexographic printing. Furthermore, proper care and storage of plates also help in achieving the best results and durability of the flexographic printing process, which in turn increases the value of the operation. The right flexographic printing plate is, therefore, not just an element; it is the basis for creating superior printed products.