Pendahuluan

In the contemporary packaging industry, packaging is not just a container, but a strategic, important choice. It is the initial handshake of your product, its silent salesman, and an essential element of its cost structure. The decision between flexible and rigid packaging, two primary types of packaging, is not just a matter of aesthetics. It is a move that will have far-reaching and long-term consequences on your supply chain, your profit margins, your brand perception, and your environmental footprint. The correct decision is not only about securing a product —true product protection— but also about presenting a brand and refining an operation. This flexible vs rigid packaging decision is mission-critical, and it cannot be analyzed as a simple box versus bag.

What is Rigid Packaging

The first and most obvious feature of rigid packaging is that it retains its shape. It is an integrity structure, which is not subject to outer force, which provides a fortress of protection of the product inside. Its identity is that of power and permanence.

The most typical and well-known materials that are related to rigid packaging are:

Glass: Glass is heavy, non-porous, and is considered a high-end material that is suitable in luxury products, drinks (like in glass bottles), and canned food items.

Metal: This is usually aluminum or tinplate, which has outstanding barrier properties and durability of cans, tins, and aerosol products.

Rigid Plastics: Bottles, jars, tubs, and clamshells are made of materials such as PET (Polyethylene terephthalate) and HDPE (High-density polyethylene).

Paperboard: Thick paper-based material that is dense and is used in high-end electronics boxes, luxury cartons (often called paperboard boxes), or liquid-filled gable-top cartons.

The main value of rigid packaging is that it has a structural protection that is uncompromising. It is the protector of the delicate and fragile products, the conventional container of the precious, and the time-tested norm of products that need long-term, durable storage.

What is Flexible Packaging

The new, versatile contender is flexible packaging. Its distinguishing feature is the contrary: it is malleable, soft, and easy to work with. It is a type that is founded on innovation, resource efficiency, and versatility. It is not a fortress, but a high-tech, form-fitting skin.

This group consists of a huge number of materials, frequently in complex mixtures:

Films and Foils: Plastic polymers (PE, BOPP, PET), aluminum foils, or metallized films.

Laminasi: Multiple layers of various materials fused to obtain certain barrier, sealing and printability properties.

Bags and Pouches: The most widespread types, such as stand-up pouches (SUPs) with zippers, pillow bags (such as chip bags), single-serving sachets, and bag-in-box liners.

Flexible packaging has emerged to the forefront by redefining the equation. It provides a fraction of the material containment, a high-definition canvas on which to brand and a new level of convenience to the end-consumer.

Rigid vs Flexible Packaging: A Head-to-Head Comparison

The rigid packaging vs flexible packaging decision between the two philosophies is not easy. What appears right on one ledger (e.g., sustainability) might appear different on another (e.g., total cost). In order to make a strategic decision, we need to break down the comparison on the five key metrics that are of utmost importance to a business.

| Category | Pengemasan yang Kaku | Kemasan Fleksibel |

| Kelebihan | – Superior structural protection (crush/impact) | – Drastically lower supply chain cost (lightweight, compact) |

| – Premium brand perception (glass/metal) | – Lower Total Cost of Ownership (TCO) | |

| – Simple, mature recycling (glass/aluminum) | – Shatterproof | |

| Kekurangan | – Very high transport & warehousing costs | – Weak structural protection (cannot be crushed) |

| – Higher Total Cost of Ownership (TCO) | – Risk of puncture | |

| – Risk of breakage (e.g., glass) | – Traditionally difficult to recycle (multi-layer) | |

| – Lower consumer convenience | – Can perceive as “cheap” (if poorly executed) |

The TCO (Total Cost of Ownership): Beyond the Unit Price

The most prevalent and expensive error when analyzing flexible vs rigid packaging cost is to be obsessed with the unit price.The price of one glass jar and one pouch is a vanity measure; the Total Cost of Ownership (TCO) is a sanity measure.

TCO does not just see the procurement line-item, but examines the whole cost ecosystem:

Material Costs: Although flexible packaging may require 70-90% less material by weight, the sophisticated technology of multi-layer films can occasionally render its unit price to appear similar to simple rigid alternatives. However, this is just the start.

Total Cost of Failure: This is an important, frequently-secretive variable. How much does a pallet of broken glass jars or broken rigid containers cost? This failure cost is not only the lost product and packaging, but the labor to clean up, the logistics of reshipment, and the immeasurable cost of a disappointed customer. Flexible packaging is also shatterproof by nature, which practically excludes this disastrous point of failure in the TCO equation.

Production Costs: Flexible packaging materials are commonly configured to high-speed form-fill-seal (FFS) operations, which raise throughput and reduce the labor costs per unit.

The TCO picture can be very different when you include the multiplier of failure and efficiency.

Weight, Size, and Supply Chain Efficiency

Here, the financial argument of flexible packaging cannot be ignored. The weight and size differences are not trifles; they are groundbreaking aspects that trickle down the whole supply chain.

Weight: A flexible pouch can be 85-95% lighter than its rigid glass counterpart. This is a dollar-to-dollar cut in shipping fuel expenses. It reduces the carbon footprint of each and every unit shipped, whether it is your factory or the distribution center, or the retail shelf.

Size (Warehousing and Inbound Freight): Rigid packaging is actually shipping air. The truckload of empty glass jars is largely empty space. Flexible packaging, which is supplied in a case or on a reel, is extremely dense. One truckload of flat pouches can substitute 10, 15, or even 20 truckloads of empty rigid containers.

Supply Chain Efficiency: The effect of these two factors is immense when combined. You are saving on fuel to ship, and real estate to warehouse. Your business is made more nimble. It is the distinction between a supply chain that is constructed using heavy, lumbering galleons and a fleet of fast, efficient destroyers.

Durability, Barrier Properties, and Shelf Life

This category is full of stereotypes. The direct supposition is that rigid is more protective. The truth is more nuanced.

Daya tahan: Rigid packaging is good at compressive force (crushing) and impact protection. In the case of a product such as a fragile lightbulb or a bottle of champagne, this structural integrity cannot be compromised. Flexible packaging is puncture-resistant but cannot resist crushing. But it is much more resistant to drops since it is shatterproof.

Barrier Properties and Shelf Life: This is the secret power of flexible packaging. A plain plastic bag does not have a good barrier property. However, the contemporary flexible packaging is an engineering wonder. It is made up of several specialized layers bonded together.

- A printable outer coating (such as PET) and scuff resistance.

- An intermediate layer (such as aluminum foil or metallized film) to offer a near-hermetic barrier to oxygen, moisture, and UV light.

- A sealing layer (such as PE). This customized blend frequently surpasses the obstacle properties of numerous hard plastics and can offer a shelf life equivalent (or even superior) to glass or metal of numerous products, a key factor in the flexible vs rigid packaging for food debate.

Sustainability and Environmental Impact

This is, by all means, the most complicated and controversial aspect of the flexible packaging vs rigid packaging comparison. There is no easy green solution.

End-of-Life Win by Rigid: Rigid packaging, specifically glass and aluminum, has a distinct and strong benefit: it can be recycled. The streams of the collection are adult and the materials can be recycled indefinitely without any quality loss. It is a straightforward, powerful and marketable environmental statement.

Life-Cycle Win of Flexible: Flexible packaging claims to take a more holistic approach, which is called a Life Cycle Assessment (LCA).

- Source Reduction: It starts with much less material. The most sustainable package is that which consumes the least of the stuff.

- Energy Production: It uses much less energy and water to produce flexible films as compared to glass or metal.

- Transport Footprint: Its low weight and volume, as mentioned in the TCO section, significantly decrease the carbon emissions of transportation.

- Landfill Impact: In case it finds its way to a landfill, it occupies a small portion of the space.

The challenge of recycling multi-material laminates has been the Achilles heel of flexible materials. Nevertheless, the industry is actively addressing this, and new mono-material, recyclable-ready flexible structures are quickly becoming the new norm. It is a question of: should we have a package that is easy to recycle, or one that uses less resources throughout its life?

Brand Image and The Consumer Experience

Here is the fight over the heart. The physical representation of your brand is packaging.

Image of Rigid: Rigid packaging has a strong story behind it of tradition, high quality and content. The sound of a heavy glass jar thudding or the sound of a metal lid popping gives an impression of dependability and luxury.

Image of Flexible: Flexible packaging is the new billboard. In a case where a rigid container has a small label, the label is the whole surface of a flexible pouch. It provides a 360-degree, high-definition canvas of photorealistic graphics, metallic inks and matte/gloss finishes. It enables a brand to scream off the shelf.

The Consumer Experience: This is where flexible really stands out. It is built for convenience.

Functionality: Resealable zippers, liquid pour spouts, tear-notches to easily open, and microwaveable-in-pouch features.

Portability: It is lightweight, fits in a bag, and it will not break.

Product Evacuation: A consumer is able to squeeze the last drop of product out of a flexible pouch, which minimizes food waste and enhances value perception. There is just no way you can get the last 10 percent of jam out of a glass jar. This in-hand experience creates a daily positive engagement with your brand.

How to Ensure Your Flexible Packaging Delivers on Its Promise

You have witnessed the huge potential of flexible packaging, to reduce TCO, to establish a sustainable life cycle, and to establish a rich brand experience.

This possibility is not an assurance.

The advantages of flexible packaging can only be achieved when it is done with accuracy. A package that is flexible and delaminates, leaks, or has muddy, uneven printing is a brand-destroying catastrophe. It is not as bad as any hard-line substitute. The gap between this potential and its performance is all in the technology that is employed to make it.

The Visual Promise: Achieving Flawless Print & Brand Consistency

Only when the art on that 360-degree branding “canvas” is perfect is it an advantage. The particular color of your brand (its Coca-Cola Red or Tiffany Blue) has to be flawless, in millions of units.

This is not a simple task. It involves accurate printing equipment, including high-speed Flexographic or Rotogravure presses. These sophisticated systems are in charge of:

Color Fidelity: Making sure that your brand colors are vivid and precise.

Registration: Ensuring that all color layers are perfectly aligned (no ghosting or blurred images).

Konsistensi: Being able to maintain that quality at high speeds, the first pouch to the millionth.

Poor printing technology leads to color drift, blurred images and an immediate feeling of a cheap product. The quality of this printing machinery is what makes your brand promise anything visually.

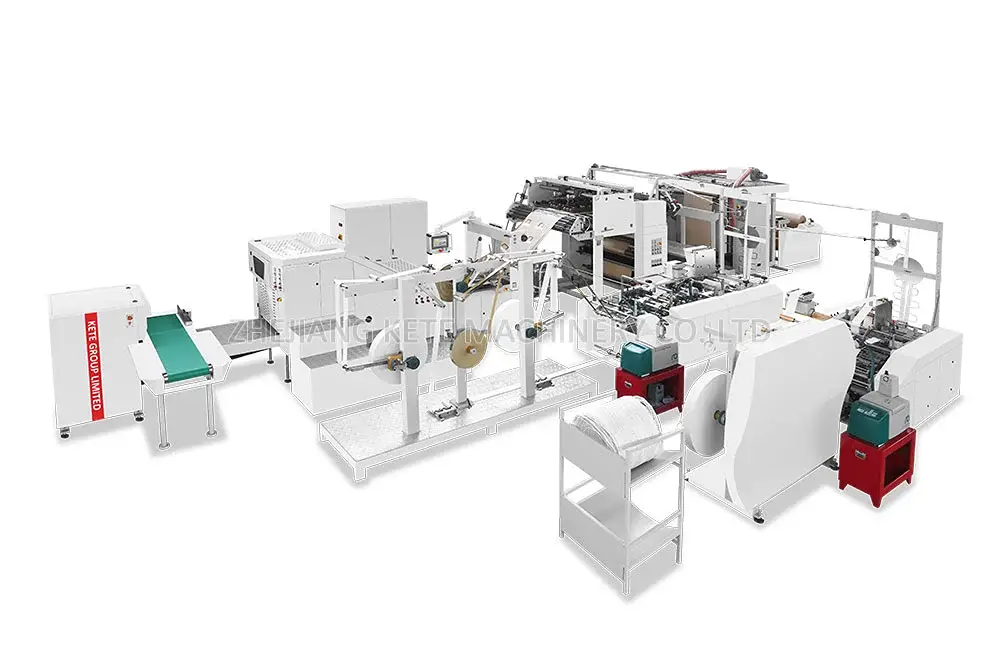

This is precisely where KETE, as a professional manufacturer known for high-performance solutions, provides the answer. We specialize in high-precision Flexographic Printing Machines engineered to solve this exact challenge. Our technology ensures flawless registration and unwavering color stability across a vast range of substrates, from plastic films and paper to non-wovens. This empowers manufacturers to confidently meet the most stringent brand standards. Furthermore, our systems are optimized for food packaging, utilizing FDA-approved, non-toxic water-based inks to deliver a final product that is as safe as it is visually stunning.

The Functional Promise: Ensuring Structural Integrity & Reliability

A leaky, beautiful pouch is a failure of functionality. The good experience that the consumer has (the zipper, the stand-up gusset, the seal) relies on the invisible side of production: packaging converting machines.

These are the machines that convert a roll of film into a finished, dependable package:

Laminators should ensure that the various layers are bonded perfectly without any bubbles or weak areas that may affect the barrier.

Slitters are required to slice the rolls with microscopic accuracy so that they can run flawlessly.

Bag-Making Machines should use the precise, uniform heat, pressure and time to create seals that will not break.

The failure of the converting process is a pouch that does not stand up, a zipper that tears, or a seal that leaks. The accuracy of this machinery is directly proportional to the functional reliability of your package.

We understand that functional reliability is non-negotiable. That is why KETE’s entire suite of converting machinery—from laminators to precision slitters and bag-makers—is engineered to deliver flawless seals and structural integrity. This commitment to manufacturing excellence is validated by our ISO 9001, CE, and RoHS certifications, ensuring reliability that we confidently back with a 1-year warranty.

Kesimpulan

The choice between rigid packaging vs flexible packaging is one of the most important strategic decisions that a business can make. No one correct answer exists. Rigid packaging is a fortress, which provides traditional strength and a definite recycling route. Flexible packaging, though, offers a new, holistic answer, a high-tech suit of armor that brings deep efficiencies, a reduced environmental impact, and an unmatched platform on which to project your brand. The best option is based on a clear-eyed evaluation of your TCO, your brand story, and your sustainability objectives. Choose wisely. And when you decide to go with the huge potential of flexible packaging, make sure your partners possess the high-tech to fulfill the promise.