En el ámbito del envasado y la impresión, que avanza rápidamente, las etiquetas cumplen una función más sofisticada que la de meros depósitos de información. Son medios para transmitir la imagen de una marca, así como el valor de un producto. En el caso de las empresas que buscan rapidez y calidad en la producción de etiquetas, la elección de la máquina de impresión flexográfica de etiquetas adecuada resulta fundamental. Esta guía le mostrará la singularidad de las impresoras flexográficas y le ayudará a elegir la máquina más adecuada para su negocio.

¿Por qué elegir la impresión flexográfica para la producción de etiquetas?

La impresión flexográfica se ha mantenido durante mucho tiempo como uno de los métodos más populares para imprimir etiquetas debido a sus ventajas únicas. Su velocidad es como la de un corredor de maratón, especialmente buena para grandes pedidos. Reduce enormemente el coste por etiqueta, lo que contribuye a aumentar la rentabilidad. Además, la impresión flexográfica es compatible con una amplia gama de sustratos, por ejemplo con papel, películas de plástico y láminas metálicas. El método de impresión flexográfica destaca en cada uno de estos sustratos. La tinta se adhiere bien a las superficies y las etiquetas impresas aguantan mucho tiempo, lo que resulta útil para etiquetas que deben permanecer elegibles durante mucho tiempo.

¿Cómo funciona una máquina de impresión flexográfica?

Los principios de las máquinas de impresión flexográfica son bastante sencillos: véalo como una técnica de "estampación". En esta técnica, las planchas flexográficas, normalmente de polímero, reciben tinta de un rodillo anilox que sirve de dispensador de cantidades exactas de pintura. Se dispensa de forma controlada. En la plancha de impresión, las partes espumadas son las que reciben la pintura, formando una imagen en relieve. A continuación, la plancha de impresión se aplica sobre el material especificado mediante un cilindro de impresión y se completa la impresión. Esta operación se realiza continuamente en serie. También puede integrarse en este proceso la aplicación de diversos revestimientos.

¿Cómo elegir la máquina impresora flexográfica de etiquetas adecuada?

Elegir una máquina de impresión flexográfica de etiquetas es como elegir la herramienta más útil para un trabajo especial. Hay que pensar detenidamente en muchas cosas diferentes.

Evalúe sus necesidades de producción

En primer lugar, sepa exactamente lo que necesita. ¿Cuál es el volumen habitual de sus pedidos? ¿Sobre qué tipos de materiales imprimirá más? ¿Cuántos colores necesita? ¿Necesitará otros pasos como troquelado, laminado o estampación en caliente justo después de la impresión? ¿Qué complejidad tienen sus productos? ¿Necesita que los colores queden perfectamente alineados?

Definir las características necesarias

En función de lo que necesite, decida qué características debe tener la máquina. Entre ellas, la anchura de impresión, la velocidad, el número de colores que puede utilizar, la gama de longitudes de impresión que puede manejar, si necesita sistemas de secado de tintas UV o al agua, el grado de automatización (como la alineación automática de colores o la limpieza) y si puede realizar otros pasos, como cortar mientras imprime.

Establezca su presupuesto

El presupuesto no debe limitarse a la compra inicial de la máquina. Piense también en los costes de instalación, formación, piezas de repuesto, elementos de uso habitual (tinta, planchas, rodillos) y los costes de mantenimiento y reparación a lo largo del tiempo.

Considerar la asistencia posventa

Una buena ayuda después de comprar la máquina es importante para que siga funcionando bien. Infórmate sobre el tiempo de garantía de la empresa que la ha fabricado o vendido. ¿Con qué rapidez te ayudan si tienes problemas técnicos? ¿Pueden enviarte fácilmente piezas de repuesto? ¿Ofrecen ayuda para instalar la máquina y formar al personal?

Solicitar demostraciones y muestras

Si puede, vea trabajar a la máquina en persona. O pídales que impriman muestras con los materiales que usted utiliza normalmente. Observe las muestras impresas para comprobar la calidad de impresión y la estabilidad de la máquina.

Evaluar la reputación del proveedor

Elegir un proveedor con mucha experiencia y un buen nombre es como elegir un guía fiable. Pueden aconsejarle mejor, asegurarse de que el equipo es de buena calidad y ofrecerle una ayuda sólida mientras compra y utiliza la máquina.

Cómo encontrar su máquina de impresión flexográfica de etiquetas específica

Con muchos modelos excelentes de impresoras flexográficas de etiquetas disponibles, cada uno diseñado con puntos fuertes específicos, para encontrar el modelo adecuado es necesario conocer sus capacidades individuales. A continuación, analizamos algunos modelos de alta calidad, destacando sus características clave y el valor que ofrecen a diferentes tipos de empresas de impresión.

KETE Serie KTLP-S60

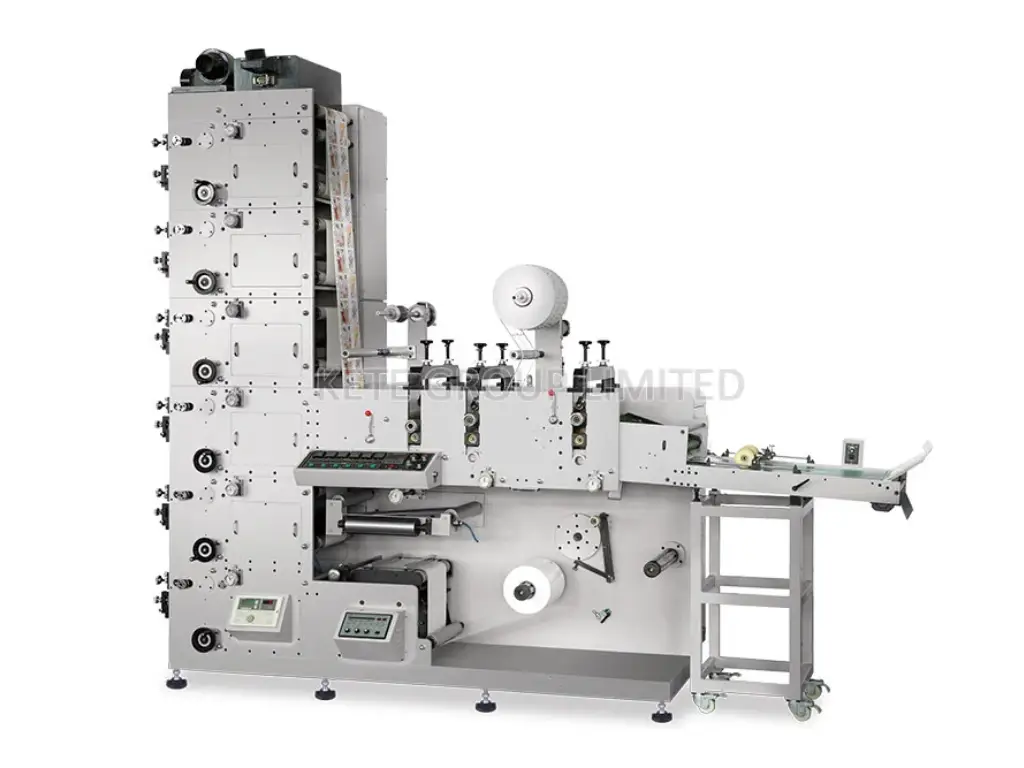

Para las empresas centradas en la producción eficiente de etiquetas adhesivas con acabado integrado, la serie KTLP-S60 de KETE es una opción convincente conocida por su flujo de trabajo integrado de una sola pasada. Esta máquina gestiona todo el proceso (desenrollado, impresión, barnizado, secado, laminado, troquelado y rebobinado) en una sola pasada. Esta capacidad "todo en uno" agiliza el flujo de trabajo y aumenta la productividad. Características técnicas clave como el cilindro anilox cerámico garantizan una transferencia de tinta precisa para una calidad constante, mientras que el control automático de la tensión y un controlador EPC proporcionan una manipulación del material estable y precisa. El ajuste de 360° de la plancha de la unidad de impresión permite un registro preciso. Equipada de serie con un secador IR (aire caliente) y una estación de troquelado en línea, y con opciones de secado UV, impresión inversa e inspección por vídeo de la banda, la serie S60 proporciona las herramientas esenciales para una producción de etiquetas adhesivas fiable y de calidad.

| Modelo | Max En bruto Material Anchura (mm) | Anchura máxima de impresión (mm) | Velocidad mecánica máxima (m/min) | Velocidad máxima de impresión (m/min) | Número de colores | Longitud de repetición de impresión (mm) | Tipo de materia prima | Desconectar/Rebobinar Diámetro (pulg.) |

| KETE KTLP-S60/320 | 320 | 310 | 60 | 50 | 1-6 | 177.8-355.6 | Etiqueta adhesiva | 600 (~23.6) |

| KETE KTLP-S60/450 | 460 | 450 | 60 | 50 | 1-6 | 177,8-355,6 / 206,3-460,3 (opc) | Etiqueta adhesiva | 600 (~23.6) |

KETE Serie KTLP-S60D

Basándose en la eficiencia de la S60, la serie KTLP-S60D de KETE está diseñada para productores de etiquetas adhesivas que requieren una mayor flexibilidad de acabado, especialmente en el troquelado y la salida. Esta máquina mantiene el eficiente proceso de una sola pasada pero añade capacidades como múltiples estaciones de troquelado, incluyendo soporte para trabajos a doble cara y corte de hojas. Los clientes se benefician de esta mayor versatilidad, que les permite manejar diseños de etiquetas y formatos de salida más complejos en una sola operación en línea. La eligen quienes necesitan una impresión fiable combinada con opciones de acabado avanzadas e integradas para diversos trabajos de etiquetas adhesivas.

| Modelo | Max En bruto Material Anchura (mm) | Anchura máxima de impresión (mm) | Velocidad mecánica máxima (m/min) | Velocidad máxima de impresión (m/min) | Número de colores | Longitud de repetición de impresión (mm) | Tipo de materia prima | Desconectar/Rebobinar Diámetro (pulg.) |

| KETE KTLP-S60D/320 | 320 | 310 | 60 | 50 | 1-6 | 177,8-355,6 / 206,3-460,3 (opc) | Etiqueta adhesiva | 600 (~23.6) |

| KETE KTLP-S60D/450 | 460 | 450 | 60 | 50 | 1-6 | 177,8-355,6 / 206,3-460,3 (opc) | Etiqueta adhesiva | 600 (~23.6) |

KETE Serie KTLP-S60L

Para impresores especializados en envases de papel más anchos, como vasos, cuencos y pajitas, la serie KTLP-S60L de KETE ofrece una solución dedicada y eficiente. Diseñada para la impresión de una sola pasada en rollos de papel de hasta 810 mm de ancho, esta máquina integra todos los pasos necesarios, desde el desenrollado hasta el rebobinado. Los clientes eligen la S60L por su capacidad para manipular formatos más anchos a una velocidad constante, proporcionando la capacidad necesaria para la producción de envases de papel. Su fiable manipulación del papel y sus procesos integrados la convierten en un valioso activo para este segmento específico del mercado.

| Modelo | Max En bruto Material Anchura (mm) | Anchura máxima de impresión (mm) | Velocidad mecánica máxima (m/min) | Velocidad máxima de impresión (m/min) | Número de colores | Longitud de repetición de impresión (mm) | Tipo de materia prima | Desconectar/Rebobinar Diámetro (pulg.) |

| KETE KTLP-S60L/620 | 620 | 610 | 60 | 50 | 4-6 | 177.8-355.6 | Papel en rollo | 600 (~23.6) |

| KETE KTLP-S60L/820 | 820 | 810 | 60 | 50 | 4-6 | 177.8-355.6 | Papel en rollo | 600 (~23.6) |

KETE Serie KTLP-NW180

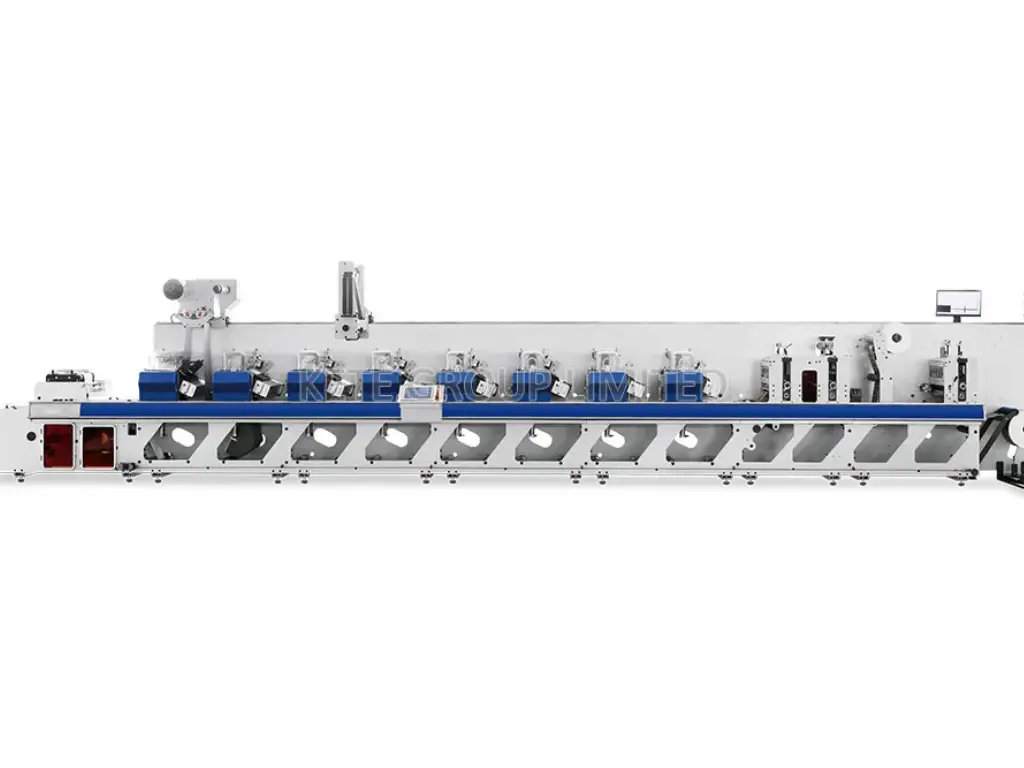

Las empresas que se enfrentan a grandes volúmenes de impresión de banda estrecha en diversos materiales, incluidos varios films de plástico y papel, deberían recurrir a la Serie KTLP-NW180 de KETE por su velocidad, precisión y versatilidad. Esta máquina flexográfica en línea destaca por su avanzado sistema de servocontrol, que garantiza una precisión excepcional a velocidades de hasta 180 m/min. Los clientes valoran su capacidad para manejar una amplia gama de sustratos y longitudes de repetición, con el apoyo de características estándar como el registro de color automático y la inspección de vídeo de la banda para una alta calidad constante. La serie NW180 es una potente inversión para aplicaciones exigentes de banda estrecha en las que el alto rendimiento y la flexibilidad del material son fundamentales para el crecimiento del negocio.

| Modelo | Max En bruto Material Anchura (mm) | Anchura máxima de impresión (mm) | Velocidad mecánica máxima (m/min) | Velocidad máxima de impresión (m/min) | Número de colores | Longitud de repetición de impresión (mm) | Tipo de materia prima | Desconectar/Rebobinar Diámetro (pulg.) |

| KETE KTLP-NW180/350 | 360 | 350 | 180 | 150 | 4-12 | 241.3-603.25 | Papel, película de plástico no retráctil | 800 (~31.5) |

| KETE KTLP-NW180/450 | 460 | 450 | 180 | 150 | 4-12 | 241.3-603.25 | Papel, película de plástico no retráctil | 800 (~31.5) |

| KETE KTLP-NW180/650 | 660 | 650 | 180 | 150 | 4-12 | 304-730.25 | Papel, película de plástico no retráctil | 1000 (~39.4) |

Marca Andy 2200

La Mark Andy 2200 es una máquina de impresión flexográfica legendaria y altamente reconocible, ampliamente considerada como un caballo de batalla en el sector de la impresión de etiquetas. Su eficiencia duradera la ha convertido en una máquina fundamental para muchas empresas de impresión de éxito a lo largo de los años. Los clientes eligen la 2200 por su probada fiabilidad y versatilidad en diferentes anchos de banda (10, 13 ó 17 pulgadas) y su capacidad para manejar hasta 12 colores. Los operarios aprecian su sencillez, con un panel de control principal que permite acceder fácilmente a todas las funciones de la rotativa. La 2200 ofrece un valor tangible a través de sus altas velocidades de funcionamiento y cambios más rápidos, lo que representa una inversión inteligente y consolidada para las empresas que priorizan un rendimiento constante y un funcionamiento sencillo.

| Modelo | Ancho de banda (pulg.) | Velocidad (ft/min) | Desconectar/Rebobinar Diámetro (pulg.) | Número de colores | Longitud de repetición de impresión (pulg./mm) | Tipo de materia prima | Unidades de troquelado | Repetición de troquelado (pulg.) |

| Marca Andy 2200 | 10/13/17 | 500-750 | 40 (~1016mm) | Máximo 12 | Mínimo 5,5-7, Máximo 24 (140-178, 610) | (No especificado) | – | – |

BOBST VISION M1

Para los convertidores que buscan una prensa que equilibre la alta calidad de impresión repetible, la eficiencia operativa y la flexibilidad en una amplia gama de sustratos, la BOBST VISION M1 es un fuerte competidor. Está diseñada para ofrecer un excelente Coste Total de Propiedad a través de características dirigidas a reducir gastos: bajos requisitos de mantenimiento, alta eficiencia energética, un recorrido de banda muy corto que minimiza el desperdicio de material y automatización que conduce a tiempos de preparación muy cortos. Las funciones de automatización, como AccuDrive para el control automático del registro y DigiGap para el control automático de la presión de troquelado, garantizan una productividad constante y la repetibilidad del proceso. La máquina también se ha diseñado para que sea fácil de usar, con funciones como el cabezal flexográfico Flower, que facilita la preparación rápida de los trabajos y los cambios sin necesidad de operarios altamente cualificados. Las funciones de conectividad permiten el acceso remoto a los datos de producción, lo que convierte a la VISION M1 en una opción muy eficiente, versátil y rentable para diversas necesidades de producción de etiquetas.

| Modelo | Ancho de banda (pulg.) | Velocidad (ft/min) | Desconectar/Rebobinar Diámetro (pulg.) | Número de colores | Longitud de repetición de impresión (pulg./mm) | Tipo de materia prima | Unidades de troquelado | Repetición de troquelado (pulg.) |

| BOBST VISION M1 | 14,6 a 16,9 | max 590 | 39.4 | máx. 10 | 6,5 a 24,0 (165 a 610) | Papel autoadhesivo, papel, cartón ligero | máx. 3 | 11,0 a 24,0 (279,4 a 609,6) |

Elegir un fabricante de confianza es importante

Como con cualquier otra decisión empresarial que tome, elegir un fabricante de confianza es crucial para el éxito de su máquina de impresión flexográfica de etiquetas. Esto influye en gran medida en la calidad de la máquina durante la fase inicial de compra, así como en su eficacia y en la asistencia que se le preste posteriormente.

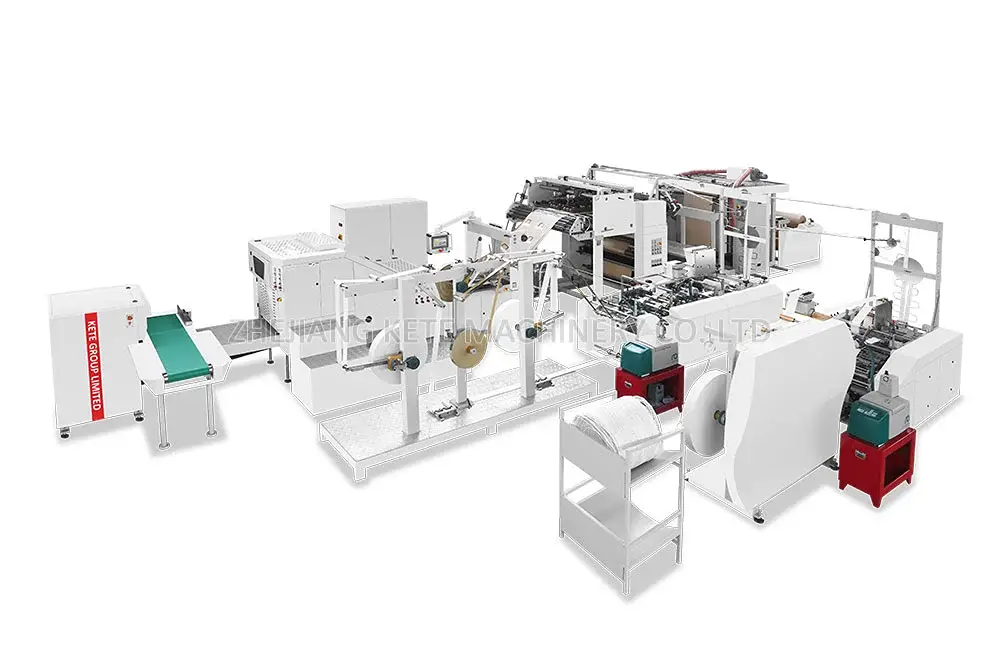

Un buen fabricante debe tener una cadena de suministro bien definida y ser capaz en general. Por ejemplo, una empresa que lleva muchos años en el mercado, vende muchas máquinas al año, tiene varias fábricas modernas y muchas líneas de producción suele tener una experiencia considerable y es capaz de producir a gran escala. Colaborar con las mejores fábricas y utilizar piezas de marcas internacionales de renombre marcan la buena calidad de los equipos. Al igual que KETE, tener clientes de todo el mundo (exportando a más de 80 países), una producción estable (más de 2000 unidades/año, 15 fábricas, 18 líneas de producción) y un riguroso control de calidad (ISO 9001, CE) demuestra que se toman en serio la calidad. Los valores de KETE son: calidad, orientación al cliente, innovación, sostenibilidad y honestidad. Desde las soluciones personalizadas hasta el servicio postventa ofrecido, los clientes reciben valor en: velocidad de producción, reducción de costes y fiabilidad de la máquina en espera.

Elegir a un socio como éste significa que usted obtiene algo más que una máquina: obtiene tranquilidad y ayuda a largo plazo.

Guía práctica de uso y mantenimiento

Comprar un equipo nuevo es sólo el primer paso. Utilizarlo y cuidarlo correctamente es clave para que siga funcionando bien durante mucho tiempo. Es muy importante formar bien a las personas que van a utilizar la máquina. Deben comprender todas las características de la máquina y las normas de seguridad.

Funcionamiento diario Consejos:

- Antes de la puesta en marcha: Asegúrese de que la alimentación y el aire están conectados correctamente, y verifique que todos los componentes de seguridad están colocados. Asegúrese de que las bandejas de tinta, los rodillos anilox y las placas de impresión están limpios y colocados correctamente.

- Carga del material: Mantenga una tensión constante mientras se asegura de que el material se carga en la unidad de desbobinado sin problemas.

- Parámetros de ajuste: Basándose en el diseño y el material de la etiqueta, asegúrese de que la velocidad de impresión, el registro de color, la tensión y la temperatura de secado están dentro de los ajustes correctos.

- Observar durante la impresión: Mantener el color, el registro y la calidad de las etiquetas impresas y realizar los ajustes necesarios. También es importante controlar los ruidos extraños o las condiciones de trabajo de la máquina.

- Parada y limpieza: Siga los pasos adecuados para detener secuencialmente la máquina una vez finalizada la impresión. Para evitar que se seque la tinta, es imprescindible limpiar rápidamente el sistema de tinta, los rodillos anilox y las rasquetas.

Regular Mantenimiento Sugerencias:

- Diariamente/por turno: Limpiar las bandejas de tinta, los rodillos anilox y las rasquetas. Comprobar el espesor de la tinta. Limpiar la tinta y el polvo de la superficie de la máquina y del área de trabajo.

- Semanalmente: Compruebe si las piezas móviles (engranajes, correas) están desgastadas o sueltas. Añada lubricante si es necesario. Compruebe que las vías de aire de la secadora están despejadas. Compruebe que los dispositivos de seguridad funcionan correctamente.

- Mensualmente: Compruebe que todos los pernos y conexiones estén apretados. Compruebe la lubricación de los cojinetes. Limpie o sustituya los filtros de aire. Compruebe si los cables y tubos están envejecidos o dañados.

- Trimestralmente/Cada seis meses: Haga que técnicos cualificados revisen y mantengan la máquina por completo. Esto incluye el sistema eléctrico, el sistema de control y el sistema de aire. Calibre los ajustes importantes.

- Piezas de recambio: Mantén un stock razonable de piezas que se desgastan con frecuencia (como cuchillas de rasqueta, juntas, algunos sensores) para poder sustituirlas rápidamente y evitar parar la máquina.

Pensar en el mantenimiento como revisión periódica de la salud puede ayudar a detener los problemas antes de que se produzcan, hacer que la máquina dure más tiempo y mantener constante la calidad de impresión.

Futuras innovaciones de las impresoras flexográficas

Los avances en la tecnología de impresión flexográfica cambian continuamente. Se prevé que los próximos cambios serán una mayor automatización (menos interacción humana, mayor precisión y mejor ritmo), la fusión con la impresión digital para la impresión híbrida (el ritmo rápido de la flexografía con la agilidad digital para cambiar la información), tintas más respetuosas con el medio ambiente, menor consumo de energía, resolución de problemas más inteligente y solución de problemas a distancia a través de Internet de las Cosas, y ecoeficiencia operativa inteligente a través de IoT. Estos cambios harán que la tecnología de impresión flexográfica sea más inteligente y eficiente.

Conclusión

Las máquinas de impresión flexográfica de etiquetas son bastante esenciales en la industria moderna actual debido a su eficacia en la creación de etiquetas. Para elegir el modelo adecuado hay que tener en cuenta ciertos requisitos previos, evaluar las opciones y la reputación del fabricante, incluidos los posibles servicios de asistencia. Además, el uso y mantenimiento adecuados del dispositivo influyen en su eficacia y eficiencia operativa a largo plazo. Esperamos que la información orientativa proporcionada en este documento le ayude a seleccionar la impresora flexográfica de etiquetas que mejor se adapte a las necesidades de su empresa y potencie su inversión, su crecimiento en el mercado y su competitividad.