In the ever-evolving modern packaging and label market within the printing industry, choosing a top-performing flexo printing machine is critical for business development. Just as important as machine selection is the choice of the company which will provide the machine. A strong partner usually serves as a good supplier whose equipment is reliable and can become a true partner for business growth. This guide will help you in mastering the strategies of flexo printing, identify the main types of machines, familiarize yourself with important industry players, and make the right machine selection.

What Is Flexo Printing?

Flexo printing is a direct and quick rotary printing method that applies a flexible, raised-image print plate. The printing plate receives various types of inks from anilox rollers. Subsequently, the plate transfers ink to the substrate. Flexo printing can handle a variety of materials and various substrates such as films, paper rolls, cardboards, non woven fabrics and metal foils. It is versatile, cost effective, has high speed printing capabilities, and is well-suited for complex tasks in various industries like label production, paper cups, and other packaging applications.

Key Types of Flexo Printing Machines

Flexo printing machines come in a few different layouts. Each type has its own advantages and works best for certain jobs.

| Tipo | Características principales | Pros | Contras | Aplicaciones típicas |

| Central Impression (CI) | All color units print around a large central cylinder | Excellent color-to-color registration, great for stretchy flexible films | Complex structure, higher cost, limited number of color units | Flexible packaging film, shrink sleeves, high-precision labels |

| Tipo de pila | Printing units stacked vertically on the press frame | Simple structure, small footprint, lower equipment cost | Registration is less precise, especially at high speeds | Paper, non-woven fabric, linerboard, simple pattern bags |

| Inline | Printing units and other process units arranged in a line | Highly modular, easy to integrate multiple processes (die-cutting, coating, etc.) online | Long machine length, registration can be affected by machine length | Labels, folding cartons, tickets, functional coatings |

Choosing the right type of machine is the first step in your purchasing decision. It directly relates to the products you want to print and your production speed needs.

How to Evaluate Potential Flexo Printing Machine Suppliers?

- History and Industry Experience: Start with the supplier’s incorporation date and their background in the industry along with the experience of the personnel. A longer history is better because it shows more accumulated expertise and greater market survival. Combating core industrial issues requires a team of experts who understand the fundamentals of the sector.

- Technology and Innovation Capability: Analyze the supplier’s s concerns with automation, digital and cutting-edge technologies. Assess their automation with regard to R&D. The effectiveness of primary market leaders in realizing new technologies is important for ensuring future competitiveness.

- Product Quality and Manufacturing Strength: Find out the particular level of the supplier’s production facilities, the scale of operations, the degree of processing of the items and their control of the quality assurance system. The quality of the equipment, including its durability and the consistency of its performance, is interrelated with its stability and service life.

- Service and Technical Support: Assess the supplier’s pre-sales consultation, installation training, after-sales response speed, and repair capabilities. A comprehensive service network providing ongoing support can minimize downtime. Effective communication channels, including email and phone, are essential.

- Customization and Flexibility: Check with the supplier whether he can offer different set configurations/special equipment tailored to fit your precise specifications. Uniqueness in global market demand requires flexibility from the equipment.

- Global Coverage and Local Support: In international purchasing, a supplier’s global sales and service network is critical. When considering global coverage, suppliers with presence in key manufacturing regions like China or extensive global sales and service networks are critical. Localized support can dramatically enhance communication and performance of the processes.

- Compliance and Sustainability: Study if the supplier observes ethics policies and has a well-defined compliance architecture. Also, social responsibility and environmental care is becoming more and more crucial.

What Can Working With Quality Suppliers Bring to Your Business?

Choosing a good supplier offers benefits that go far beyond just getting a piece of equipment. They are a key support for your production process.

- High Equipment Reliability: This means fewer breakdowns and unexpected stops, ensuring continuous, efficient production.

- Optimized Production Efficiency: Using advanced technology and automation leads to faster production speeds and less waste, directly contributing to your profitability.

- Excellent Print Quality: This helps you meet or exceed the high standards needed for product packaging and labels.

- Timely Technical Support: When issues come up, you can get fast, professional help.

- Access to Innovation: Quality suppliers often drive industry advancements, allowing you to use the latest technologies.

- Strong Partnership: The best suppliers are more than just sellers; they are your technical advisors and long-term partners, providing continuous support as your business grows. Just as a good guide can help you navigate difficult terrain, a quality supplier can steer your production towards success.

Quality Leaders in Flexo Printing Machine

Within flexo printing equipment, there are a plethora of reputable suppliers from which to choose. Each one specializes in certain segments of the market, or in particular areas of technology. Getting to know them and their distinct traits might be helpful for you when seeking suppliers. This, however, is only a selection of important players from the industry.

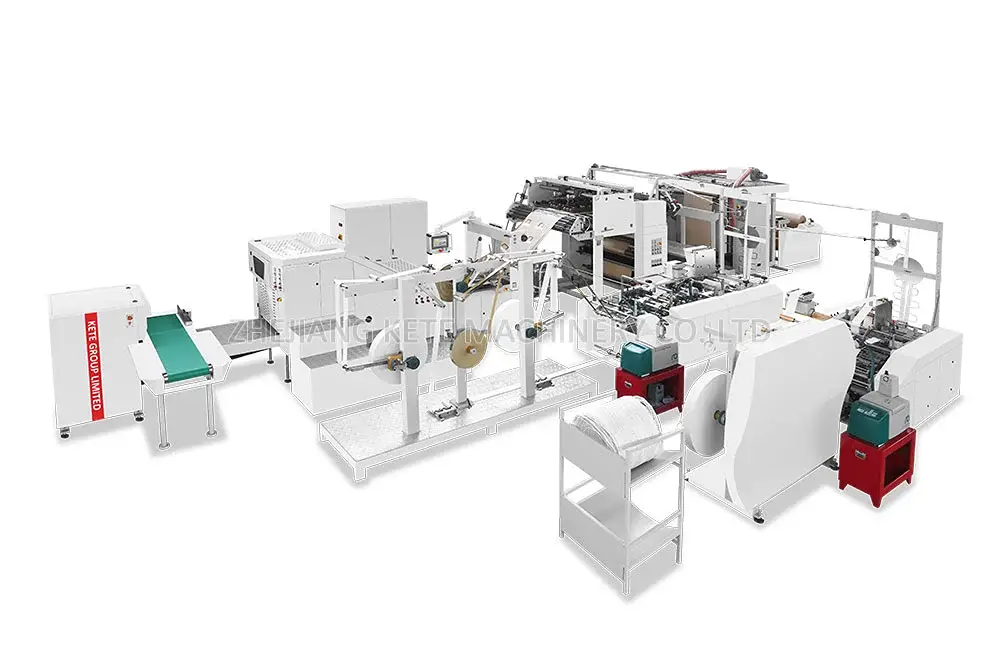

KETE

While established in 2011, KETE leverages principal staff and associates factories with deep industry roots since the 1980s. They specialize in providing in-line type, stack type, and central impression (CI) flexo presses. Their machines are designed to print on a wide range of materials, including plastic film, paper, non woven fabric, aluminium foil, PP woven fabric, and tissue paper. These presses offer speeds up to 500 meters per minute (for Gearless CI models), typically come with 2 to 8 colors, and handle printing widths from 600 to 2400 mm, compatible with water base, solvent base, or UV inks. As part of their one-stop flexible packaging solutions, they also supply related equipment such as rubber flexo plate making/mounting machines and anilox cleaning systems. KETE emphasizes high quality, adhering to ISO 9001 and CE standards with detailed QC processes that include multiple checks and providing photos/videos at key production nodes. They provide robust support, including a 2 Year Warranty, prompt after-sales service with potential on-site assistance, spare parts support for common wear items, and online system upgrades for most models. Their scale, with 18 lines across 15 plants producing over 2,000 units annually, demonstrates their manufacturing capacity and global reach in over 80 countries.

Mark Andy

With over 75 years of history, Mark Andy is a global leader in narrow and mid-web flexo printing and converting equipment, especially strong in labels and flexible packaging. The company offers a full lifecycle solution covering equipment, services, and supplies, and has a large customer support team. Mark Andy focuses on understanding each customer’s unique business needs to provide products and services that improve their productivity, efficiency, and potential. Their brands like Presstek and Rotoflex are also well-known.

Nilpeter

Having more than a century of engineering experience, Nilpeter is a global leader in producing narrow and mid-web label and flexible pouch printing equipment using modern and offset digital printing technologies. They focus strongly on innovation to assist customers in maximizing shifts in production processes and rethinking new opportunities. Nilpeter has major production branches in Europe, the USA, and Asia, and he operates in sixty five countries with about five hundred employees . They provide high quality services at reasonable prices because of their vast business experience and lean production methods. They were among the first in the world to apply UV-flexo printing technology.

Gallus

Founded in 1923, Gallus is a long-standing supplier focusing on supporting label and folding carton printers. It is now the label division of the well-known printing press manufacturer, Heidelberger Druckmaschinen AG. Gallus is considered a pioneer in flexo label printing, having introduced the first flexo label printing press in 1950. The company focuses on customer needs, applies Lean/Six-Sigma manufacturing concepts, has a global sales and service network (strengthened by its integration with Heidelberg), and is committed to corporate sustainability.

Bobst

Source: https://www.bobst.com/usen/

In 1890 Bobst began operating and is now one of the best in the world for equipment and services used in the processing of substrates, printing and converting. They serve industries such as labels, flexible packaging, folding carton and corrugated board. With numerous production plants and employees worldwide, BOBST is one of the leading (1st or 2nd) companies in its market segments. They are a major force driving innovation and digital transformation in the industry, visioning a connected production workflow via their BOBST Connect platform. Also, it shows great concern for sustainability. With its enormous size and technical prowess, BOBST is the forerunner in the packaging industry.

Comexi

Founded in 1954, Comexi is an international leader providing comprehensive equipment solutions for the flexible packaging sector, including printing (flexo), laminating, slitting, bag making, etc. As a family business now led by the third generation, Comexi’s core principles are customer focus, sustainability, and proximity. They have 5 global hubs offering local technical support and spare parts. Comexi has an advanced Technological Centre for R&D and training. They are known for providing highly configurable solutions and have obtained many international certifications (full ISO range, Great Place to Work), ensuring high product and service quality. They have a history of flexo innovation, including CI presses and sleeve systems.

Uteco

Founded in 1985 and situated in Italy, Uteco has always valued innovation, flexibility, and sustainability. Their main focus is developing technologies that are environmentally safe, such as water-based inks and Electron Beam curing systems. Uteco was awarded an Ecovadis Bronze medal for having actively contributed to the sustainability of flexo printing by helping establish sustainability criteria for CI flexo presses which underscores their commitment to sustainability. With extensive R&D and production facilities, the company has branches in North America for example. “Flex-converting” is their mission express and that is to offer unique customer-centric solutions devoted to people and the environment.

OMSO

Source: https://www.omso.it/en

OMSO was founded in the year 1952 and is known for its advanced machines which print on various objects and containers, such as bottles, tubes, and jars. Their technology uses flexography, dry offset, and screen printing, with additional digital options available. OMSO is a leader in its specific niche application area. They have well documented policies for product’s quality control (ISO 9001, proprietary online QC systems like Ecovision/Ecolin) and serve leading customers from food, chemicals, pharmaceuticals, and cosmetics industries where high QC on prints on containers are imperative. OMSO has a wide global network of agents and sells her products to 85 countries. OMSO actively undertakes other initiatives such as environmental protection by advocating for technologies like LED curing.

Koenig & Bauer

For more than two centuries the company Koenig & Bauer (K&B) has been one of the pioneers in the global printing machinery industry. K&B has strategically acquired businesses to expand its product line, for example acquiring Flexotecnica in 2013, which moved K&B into the flexible packaging flexo market, and partnering with Celmacch in 2022 which brought in the corrugated board flexo and converting market. Because K&B is such a large company, they offer great value to compliance (certified with ISO 37001 for anti-corruption), technological innovation (including digitalization, automation), and a comprehensive sustainability strategy.

HEMINGSTONE

Established in 1979, HEMINGSTONE Machinery Co., Ltd. specializes in equipment for plastics bag making, which includes flexo printing machines as part of their whole plant solutions. With a dedicated high-speed flexographic printing machine division established in 2006, HEMINGSTONE focuses on superb technology, strong R&D capabilities, and providing satisfactory services. They are committed to high product quality and performance, adhering to international standards like ISO 9001 and CE marks. A reputed brand in Asia, supported by an energetic overseas after-sales team, they are actively expanding their presence globally.

Choosing the Right Flexo Printing Machine

While evaluating suppliers, it is very important to clearly define the specific requirements for the machine you need. Choosing the right machine is like picking the perfect tool for your specific job.

Define Your Printing Needs

Determine the materials you will print on, their thickness and roll width (substance, thickness, roll width), number of colors, print quality, production volume, and check if there are other jobs you would like integrated online (like die-cutting, coating, laminating, or closing bags). Clearly defined objectives help in streamlining equipment selection.

Understand Machine Types & Configurations

Look back at the main types of flexo printing machines and choose the structure (CI, Stack, or Inline) that best suits your products. Also, decide on the machine’s specific setup, such as the number of color stations, drying system type (hot air, UV, EB), and roll handling systems (unwind, rewind, automatic splicing).

Match Production Volume & Speed

Your calculated annual output alongside your target production pace will dictate the necessary requirements for the machine width, maximum speed and level of automation. Typically, high volume requirements lead to needing a wider and faster machine that is fully automated. The machine’s production output acts like the heartbeat of the factory, establishing the cadence for production.

Assess Required Automation Level

Automation features (like automatic registration, auto wash, automatic roll change, inline inspection systems) can greatly improve production efficiency, reduce waste, and minimize manual work. Based on your budget and goals for efficiency gains, decide how much automation you need. This is similar to flying an airplane; higher automation can reduce the pilot’s workload and make operations more precise and efficient.

Analyze Costs & Return on Investment (ROI)

In addition to the purchase price, assess shipping, installation, training, consumables (inks, plates, blades, solvents), energy, maintenance, and labor. Determine the Total Cost of Ownership (TCO) and assess the payback period in relation to the production advantages and profits. Buying a flexo printing machine is a significant capital expense; it’s not spending money, but investing for future profit. Sustainable investment can be achieved when returns are analyzed meticulously alongside costs.

Conclusión

The choice of a flexo printing machine and supplier is a crucial business step and requires understanding internal needs, knowledge of equipment classification, and cross-analysis of potential partners. Thorough analysis leads to making thoughtful decisions, thus finding the right flexo equipment, tools, and accessories along with proper suppliers that optimally match the business requirements will greatly help in streamlining production processes, enhancing quality standards of products manufactured, and maintaining a competitive edge for a longer period of time. Doing business due diligence increases efficiency during the process of working with partners and streamlines efforts for enhancing productivity as well, something that pays off significantly in the long run. Every decision made shapes the company’s journey in the industry.