In der modernen wettbewerbsorientierten Welt der Industrie, insbesondere in der flexiblen Verpackungsindustrie und im Bereich der Materialverarbeitung, hängt der Betrieb eines Unternehmens davon ab, wie genau und effizient es ist. Die Effizienz, mit der ein Folienschneider oder eine andere Folienschneidmaschine breite Rollen in schmalere Rollen umwandeln kann, wirkt sich auf die Produktionskosten, die Produktqualität und die Wettbewerbsposition auf dem Markt aus. Bei dieser Auswahl geht es nicht einfach um den Kauf der Ausrüstung, sondern um eine Entscheidung von höchstem strategischen Wert für die Expansionsbemühungen Ihres Unternehmens. Vereinfacht ausgedrückt, ist es so, als ob Sie ein leistungsstarkes "Herz" in Ihre Produktionslinie einbauen würden.

Warum ist die Wahl der richtigen Schneidemaschine wichtig?

Stellen Sie sich vor, auf welche Herausforderungen Sie stoßen werden, wenn Sie Geräte einsetzen, die nicht optimal auf Ihre Bedürfnisse zugeschnitten sind. Geringe Effizienz in der Produktion kann zu Engpässen führen, instabiler Betrieb kann zu hohen Ausschussraten führen, und auch die Liefertermine könnten gefährdet sein. Die Kosten steigen, und außerdem wird das Vertrauen der Kunden verspielt. Eine geeignete Schneidemaschine ermöglicht die Herstellung der benötigten Rollen mit glatten Kanten und einer straffen, gleichmäßigen Wicklung, was die Produktionseffizienz erheblich steigert, den Ausschuss reduziert und die Wettbewerbsfähigkeit auf dem Markt erhöht. Für die Kunden bedeutet dies, dass sie Verpackungen und andere Güter zum besten Preis erhalten.

Gängige Typen von Rollenschneidern für das Schneiden von Folien

Die Einteilung der Schneidemaschinen ergibt sich aus der Anordnung ihrer Auf- und Abwicklungssysteme, die ihre Produktivität und Eignung für unterschiedliche Mengen und Arten von Gütern stark beeinflussen.

- Simplex-Schneider: Diese Maschinen verfügen über eine einzige Aufwickelwelle, die als Wickelkern dient. Das System hält nach einem Wickelzyklus an, damit der Bediener die fertigen Rollen entnehmen und neue Hülsen einsetzen kann. Simplex-Rollenschneidmaschinen sind aufgrund ihrer einfacheren Konstruktion etwas preiswerter und eignen sich daher für geringere Produktionsmengen oder in Fällen, in denen Stillstandzeiten beim Entladen zulässig sind.

- Duplex Schlitzer: Diese verfügen über zwei Aufwickelwellen, so dass ein kontinuierliches Schneiden und Aufwickeln möglich ist. Während eine Welle einen Satz fertiger Rollen aufwickelt, wird die andere Welle für den nächsten Satz vorbereitet. Nach Fertigstellung des ersten Satzes erfolgt die Bahnübergabe an die zweite Welle mit minimaler Verzögerung. Dies erhöht die Effizienz erheblich und macht diese Konstruktion für mittlere bis hohe Produktionsmengen geeignet.

- Revolverschneider: Revolverschneidemaschinen sind die am stärksten automatisierten und effizientesten in dieser Kategorie. Sie verfügen in der Regel über zwei Sätze von Duplex-Aufwickelwellen, die auf einem rotierenden Revolverkopf montiert sind. Dadurch können die fertigen Rollen automatisch abgetrennt und an das nächste Kernpaar auf dem Revolverkopf angehängt werden, während die Maschine mit Höchstgeschwindigkeit arbeitet. Dadurch werden die Stillstandszeiten zwischen den Rollensätzen reduziert, was bei der Herstellung sehr großer Mengen dünnerer Rollen von entscheidender Bedeutung ist.

Geeignete Materialien und Anwendungen für Folienschneidmaschinen

Folienschneidmaschinen werden in fast allen Branchen eingesetzt, in denen flexible Rollenmaterialien in schmalere Streifen umgewandelt werden. Beispiele für solche Materialien sind unter anderem:

- Verschiedene Kunststofffolien: PET, BOPP, CPP, PE, PVC-Folie, PI, PVA, PTFE, usw., weit verbreitet in der Elektronik, Optik, Schutz, Isolierung und anderen Bereichen.

- Papier: Verschiedene Verpackungspapiere, Spezialpapiere, Trennfolien, selbstklebendes Papier usw.

- Metallfolien: Aluminiumfolie, Kupferfolie, usw.

- Nicht gewebte Stoffe: Vliesstoffe für die Bereiche Medizin, Hygiene und Verpackung.

- Laminate/Verbundwerkstoffe: Lebensmittelverpackungslaminate, Industrielaminate, usw.

- Etikettenmaterial: Selbstklebende Etikettenrollen.

Die Endprodukte dieser Maschinen werden in zahlreichen Branchen eingesetzt:

- Verpackung: Flexible Verpackungen, Etiketten, Bänder, Kartons, etc.

- Drucken: Verarbeitung von Rollenmaterialien nach dem Druck für die anschließende Weiterverarbeitung oder Beutelherstellung.

- Etikettieren: Schneiden von selbstklebenden Materialien zur Herstellung verschiedener Etikettenrollen.

- Herstellung von Klebebändern: Schneiden von Jumbo-Rollen verschiedener Bänder.

- Elektronik: Optische Folien, Batterieseparatoren, Trennfolien und andere Präzisionsmaterialien.

- Hygieneprodukte: Verarbeitung von Vliesstoffen und Folienmaterialien.

- Industriell: Schutzfolien, Klebebänder, Baumaterialien, usw.

Unabhängig davon, ob Sie mit flexiblen Verpackungsmaterialien arbeiten oder ein Endverbraucher in den Bereichen Lebensmittel und Getränke, Schönheit und Körperpflege, industrielle Fertigung oder sogar Logistik sind, die Schärfe und Konsistenz Ihrer Verpackungslösungen hängt von einer Hochleistungsschneidemaschine ab.

Wie wählen Sie Ihre Folienschneidmaschine aus?

Die Wahl der besten Schneidemaschine für Ihre Produktionsprozesse erfordert viel Liebe zum Detail und Fachwissen. Dies sind die wichtigsten Bewertungskriterien:

Beurteilen Sie Ihren Materialbedarf

Bestimmen Sie zunächst die Art der Materialien, mit denen Sie hauptsächlich arbeiten müssen. Handelt es sich um Platten oder Folien? Handelt es sich um einlagige Materialien oder um Verbundmaterialien? Faktoren wie Materialdicke, -breite, -flexibilität und Oberflächeneigenschaften wie statische Anhaftung oder Glätte wirken sich alle auf die Maschineneinrichtung aus. Die Verarbeitung ultradünner Folien oder hochdehnbarer Materialien erfordert fortschrittliche Systeme zur Spannungssteuerung und statischen Kontrolle.

Anforderungen an das Produktionsvolumen bestimmen

Wie hoch ist Ihre angestrebte Jahres- oder Schichtproduktion? Dies bestimmt direkt die Maschinengeschwindigkeit und den Automatisierungsgrad, den Sie benötigen. Wenn Sie große Rollen verarbeiten müssen, benötigen Sie Maschinen mit größeren Abwickeldurchmessern und höheren Geschwindigkeiten. Klare Produktionsziele helfen Ihnen, die Modelle einzugrenzen, die Ihre Effizienzanforderungen erfüllen.

Definieren Sie Qualitätsstandards

Was sind Ihre spezifischen Anforderungen an die Qualität der fertigen Rollen? Müssen die Schnittkanten vollkommen glatt sein, ohne Grate oder Ausfransungen? Muss die Wickelhärte der fertigen Rollen sehr gleichmäßig sein, um Teleskopieren oder Dishing zu vermeiden? Diese Anforderungen bestimmen die erforderlichen Präzisionskontrollsysteme an der Maschine, wie z. B. eine hochpräzise Zugregelung, Kantenführungssysteme (EPC) und den geeigneten Aufwickelwellentyp (z. B. sind Differenzialwellen für Materialien mit Spannungsschwankungen über die Bahn hinweg von Vorteil, während Luftwellen vielseitig einsetzbar sind).

Berücksichtigen Sie Ihr Budget

Das Budget ist vielleicht das wichtigste Detail, wenn es darum geht, eine Entscheidung zu treffen. Neben den Erstanschaffungskosten sollte ein Budget auch die laufenden Betriebskosten, die Wartungs- und Instandhaltungskosten, die Energierechnungen sowie die Kapitalrendite durch Produktivitätssteigerung und Abfallvermeidung berücksichtigen. Auch wenn der Anschaffungspreis für eine qualitativ hochwertige Maschine anfangs hoch sein mag, werden sich die reduzierten langfristigen Kosten im Laufe der Zeit als äußerst vorteilhaft erweisen.

Automatisierungsgrad auswerten

Welchen Grad der Automatisierung benötigen Sie? Vom manuellen Be- und Entladen bis hin zum vollautomatischen Beladen, Spleißen, Spannungskontrolle und robotergestütztem Rollenhandling sind verschiedene Automatisierungsgrade mit unterschiedlichen Investitionen und Arbeitskosten verbunden. Ein höherer Automatisierungsgrad bedeutet im Allgemeinen eine höhere Effizienz und weniger Betriebsfehler, was zu einer reibungsloseren Produktion führt.

Erkundung von Modellen hochwertiger Folienschneidemaschinen

Mit diesen Auswahlkriterien im Hinterkopf stellen wir Ihnen im Folgenden einige der renommiertesten Folienschneid- und -aufwickelmaschinen auf dem Markt vor. Jedes Modell hat spezifische Vorteile, die sich mit bestimmten Problemen in der Produktion befassen und Ihnen helfen, eine optimale Produktionseffizienz zu erreichen.

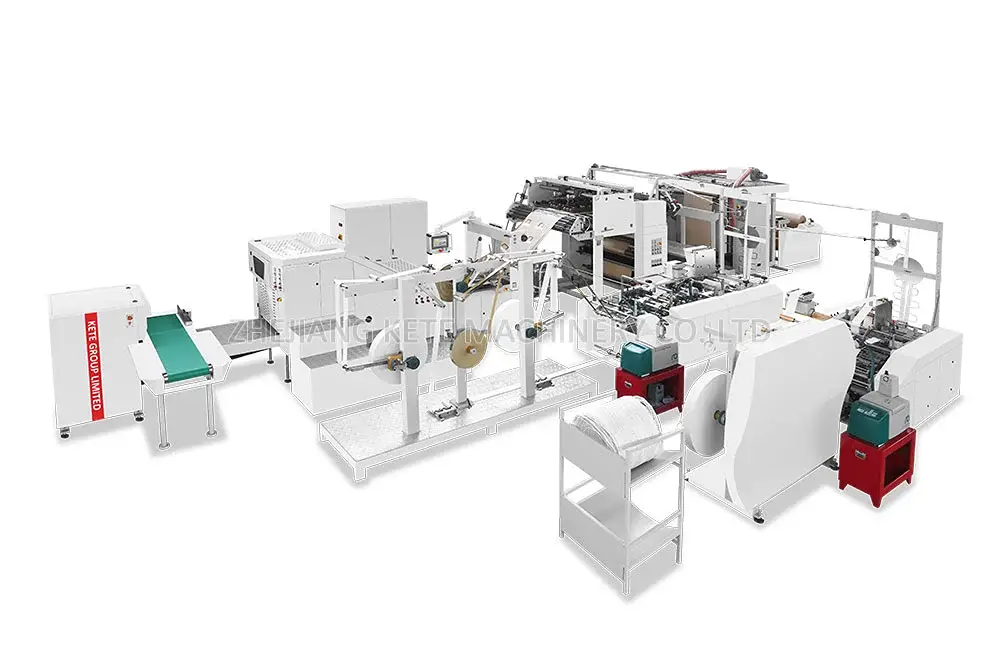

KETE KTSM-C600G Reihe

Der leistungsstarke Dompteur von Jumbo-Papierrollen - KETE KTSM-C600G Serie. Für Unternehmen, die eine bahnbrechende Produktivität suchen, ist diese leistungsstarke Rollenschneidmaschine perfekt für die Verarbeitung besonders großer Papierrollen. Mit einer sehr hohen Geschwindigkeit von 600 m/min und sehr großen Abwickel-/Aufwickeldurchmessern von Φ1600mm/Φ1300mm verwandelt er Jumbo-Rollen mühelos in hochpräzise Fertigrollen. Damit sind Sie dem Wettbewerb beim Schneiden von Papier weit voraus. Jede Rolle profitiert von der Präzision des rotierenden Scherschnitts und der stabilen Aufwicklung über eine Luftwelle, die die Einhaltung der Qualitätsstandards sicherstellt. Die K620CG bietet die Flexibilität, einen extrem hohen Ausstoß zu steuern und eine Chance auf dem Markt zu ergreifen.

| Technische Daten der Maschine | Modell KTSM-C600G/1800 | Modell KTSM-C600G/2600 |

| Struktur der Rückspulung | Duplex-Rückspulung | Duplex-Rückspulung |

| Max. Breite des Rohmaterials | 1800 mm (71 Zoll) | 2600mm (102.4") |

| Max. Abwickeldurchmesser | Φ1600mm (63") | Φ1600mm (63") |

| Max. Aufwickel-Durchmesser | Φ1300mm (51,2") | Φ1300mm (51,2") |

| Min. Schlitzbreite | 30mm (1.18") | 30mm (1.18") |

| Max. Mechanische Geschwindigkeit | 600m/min | 600m/min |

| Papierkern Innendurchmesser | 76mm/152mm (3"/6") | 76mm/152mm (3"/6") |

| Schlitztechniken | Rotationsscherenschnitt (pneumatisch) | Rotationsscherenschnitt (pneumatisch) |

| Entfernen der Trimmung | Trimm-Sauggebläse | Trimm-Sauggebläse |

| Luftzufuhr | 0,6-0,8 Mpa (0,8m³/min) | 0,6-0,8 Mpa (0,8m³/min) |

| Gesamtleistung | 95kw | 95kw |

| Maschine Gewicht | 12000kg | 12000kg |

| Größe der Maschine (LWH) m | 6150x4600x2300mm | 6150x4600x2300mm |

| Maschinenleistung | 5Linien 3 Phase 220/380/440V 50/60HZ | 5Linien 3 Phase 220/380/440V 50/60HZ |

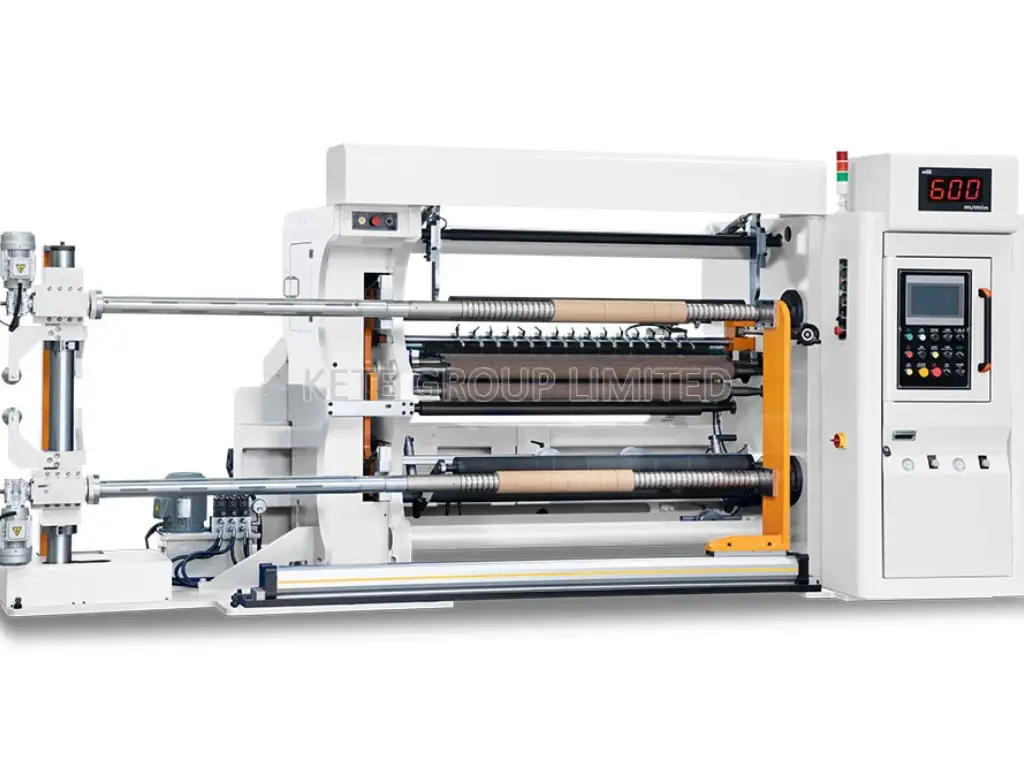

KETE KTSM-C600 Reihe

Die Hochgeschwindigkeitsmaschine für das Schneiden flexibler Verpackungen - KETE KTSM-C600 Serie. Sie ist eine wendige Hochgeschwindigkeits-Schneidemaschine für viele flexible Kunststofffolienrollenmaterialien wie PET, BOPP, CPP und einige Papiere. Mit Standardrollendurchmessern von Φ600mm beim Abwickeln und Φ450mm beim Aufwickeln verfügt die Maschine über eine enorme Leistung von 600 m/min und verdoppelt damit die Produktionseffizienz. Die fertigen Rollen werden durch präzises Schneiden und intelligentes Aufwickeln mit Differentialwelle hergestellt, was perfekt glatte Kanten und eine straffe und gleichmäßige Wicklung garantiert. Die C600 Serie erreicht hohe Stückzahlen, flexibles Schneiden und hohe Effizienz.

| Technische Daten der Maschine | Modell KTSM-C600/ 1100 | Modell KTSM-C600/ 1300 |

| Struktur der Rückspulung | Duplex-Rückspulung | Duplex-Rückspulung |

| Max. Breite des Rohmaterials | 1000mm (39.4") | 1200mm (47.2") |

| Max. Abwickeldurchmesser | Φ600mm (23,6") | Φ600mm (23,6") |

| Max. Aufwickel-Durchmesser | Φ450mm (17,7") | Φ450mm (17,7") |

| Min. Schlitzbreite | 50mm (1.97") | 50mm (1.97") |

| Max. Mechanische Geschwindigkeit | 600m/min | 600m/min |

| Papierkern Innendurchmesser | 76mm/152mm (3"/6") | 76mm/152mm (3"/6") |

| Schlitztechniken | Rasierklinge in der Luft | Rasierklinge in der Luft |

| Entfernen der Trimmung | Gebläse | Gebläse |

| Luftzufuhr | 0,6-0,8 Mpa (0,8m³/min) | 0,6-0,8 Mpa (0,8m³/min) |

| Gesamtleistung | 25kw | 28kw |

| Maschine Gewicht | 4500kg | 5000kg |

| Größe der Maschine (LWH) | 2500x4000x2200mm | 2800x4300x2200mm |

| Maschinenleistung | 5Linien 3 Phase 220/380/440V 50/60HZ | 5Linien 3 Phase 220/380/440V 50/60HZ |

KETE KTSM-C400L Reihe

Der Schlüssel zur Erweiterung Ihrer Produktmöglichkeiten - KETE KTSM-C400L Serie. Wenn Sie flexible Materialien von großen Fertigrollen mit Durchmessern von bis zu Φ800 mm abwickeln möchten, dann ist diese Maschine genau das Richtige für Sie, denn sie kann Abwickelrollen bis zu Φ1800 mm verarbeiten und Fertigrollen mit einer konstanten Geschwindigkeit von 400 m/min effizient aufwickeln. Der Bedarf an vielseitigen, hochwertigen Anwendungen für flexible Materialien mit großen Fertigrollendurchmessern erfordert eine hohe Schnittgenauigkeit der Rotationsschere mit präziser Differenzialwellensteuerung. Die KTSM-C400L erweitert Ihre Produktpalette und erfüllt die Anforderungen von Nischenmärkten, wobei sie auch bei großen Durchmessern eine hervorragende Qualitätssicherung bietet.

| Technische Daten der Maschine | Modell KTSM-C400L/ 1300 | Modell KTSM-C400L/ 1700 |

| Struktur der Rückspulung | Duplex-Rückspulung | Duplex-Rückspulung |

| Max. Breite des Rohmaterials | 1200mm (47.2") | 1600mm (63") |

| Max. Abwickeldurchmesser | Φ1800mm (70.8") | Φ1800mm (70.8") |

| Max. Aufwickel-Durchmesser | Φ800mm (31,5") | Φ800mm (31,5") |

| Min. Schlitzbreite | 30mm (1.18") | 30mm (1.18") |

| Max. Mechanische Geschwindigkeit | 400m/min | 400m/min |

| Papierkern Innendurchmesser | 76mm/152mm (3"/6") | 76mm/152mm (3"/6") |

| Schlitztechniken | Rotationsscherenschnitt | Rotationsscherenschnitt |

| Entfernen der Trimmung | Gebläse | Gebläse |

| Luftzufuhr | 0,6-0,8 Mpa (0,8m³/min) | 0,6-0,8 Mpa (0,8m³/min) |

| Gesamtleistung | 12kw | 15kw |

| Maschine Gewicht | 3800kg | 4000kg |

| Größe der Maschine (LWH) | 2200x4000x2100mm | 2200x4300x2100mm |

| Maschinenleistung | 5Linien 3 Phase 220/380/440V 50/60HZ | 5Linien 3 Phase 220/380/440V 50/60HZ |

KETE KTSM-C400 Reihe

Ihr zuverlässiger Allzweck-Hochgeschwindigkeits-Partner - die KETE KTSM-C400 Serie. Für Unternehmen, die einen angemessenen Wert für ihre Investition bei gleichzeitiger konsistenter Verarbeitung verschiedener flexibler Verpackungsmaterialien erzielen wollen, ist die KTSM-C400-Serie eine hervorragende Lösung. Sie bietet eine Hochgeschwindigkeitsleistung von 400 m/min, und Standard-Rollendurchmesser sind problemlos zu bewältigen (Φ600mm Abwickeln, Φ450mm Aufwickeln). Durch den Einsatz einer präzisen Differentialwellenaufwicklung in Verbindung mit einem effektiven Rasiermesserschnitt wird eine stabile und qualitativ hochwertige Produktion gewährleistet. Durch die Entscheidung für die C400-Serie erhalten Unternehmen eine wettbewerbsfähige, vielseitige und effiziente Lösung für das Schneiden.

| Technische Daten der Maschine | Modell KTSM-C400/ 1100 | Modell KTSM-C400/ 1300 |

| Struktur der Rückspulung | Duplex-Rückspulung | Duplex-Rückspulung |

| Max. Breite des Rohmaterials | 1000mm (39.4") | 1200mm (47.2") |

| Max. Abwickeldurchmesser | Φ600mm (23,6") | Φ600mm (23,6") |

| Max. Aufwickel-Durchmesser | Φ450mm (17,7") | Φ450mm (17,7") |

| Min. Schlitzbreite | 50mm (1.97") | 50mm (1.97") |

| Max. Mechanische Geschwindigkeit | 400m/min | 400m/min |

| Papierkern Innendurchmesser | 76mm/152mm (3"/6") | 76mm/152mm (3"/6") |

| Schlitztechniken | Rasierklinge in der Luft | Rasierklinge in der Luft |

| Entfernen der Trimmung | Gebläse | Gebläse |

| Luftzufuhr | 0,6-0,8 Mpa (0,8m³/min) | 0,6-0,8 Mpa (0,8m³/min) |

| Gesamtleistung | 12kw | 15kw |

| Maschine Gewicht | 3800kg | 4000kg |

| Größe der Maschine (LWH) | 2200x4000x2100mm | 2200x4300x2100mm |

| Maschinenleistung | 5Linien 3 Phase 220/380/440V 50/60HZ | 5Linien 3 Phase 220/380/440V 50/60HZ |

KETE KTSM-C350P Reihe

Unerschrockener Bezwinger komplexer Materialien, zuverlässiger Schutz für Jumbo-Fertigrollen - KETE KTSM-C350P Serie. Die vollautomatische Rollenschneidmaschine KTSM-C350P ist ein Meister der Vielseitigkeit in Sachen Materialkompatibilität. Sie schneidet und zerkleinert schwierige Bahnmaterialien wie Klebeetiketten, Laminate, Papier und Folien einwandfrei. Die KTSM-C350P ist mit einem präzisen rotierenden Scherenschnitt bei 350 m/min und einer gleichmäßigen Luftwellenaufwicklung ausgestattet und bietet damit auch unter anspruchsvollen Bedingungen nahtlose Flexibilität und außergewöhnliche Zuverlässigkeit. Darüber hinaus verarbeitet sie Jumbo-Abwickelrollen von Φ1200mm und liefert bemerkenswerte fertige Rollen von Φ1000mm in extremen Dimensionen, die auch großen Durchmesseranforderungen gerecht werden.

| Technische Daten der Maschine | Modell KTSM-C350P/ 1300 | Modell KTSM-C350P/ 1600 |

| Struktur der Rückspulung | Duplex-Rückspulung | Duplex-Rückspulung |

| Max. Breite des Rohmaterials | 1200mm (47.2") | 1500mm (59") |

| Max. Abwickeldurchmesser | Φ1200mm (47,2") | Φ1200mm (47,2") |

| Max. Aufwickel-Durchmesser | Φ1000mm (39,4") | Φ1000mm (39,4") |

| Min. Schlitzbreite | 50mm (1.97") | 50mm (1.97") |

| Max. Mechanische Geschwindigkeit | 350m/min | 350m/min |

| Papierkern Innendurchmesser | 76mm/152mm (3"/6") | 76mm/152mm (3"/6") |

| Schlitztechniken | Rotationsscherenschnitt | Rotationsscherenschnitt |

| Entfernen der Trimmung | Gebläse | Gebläse |

| Luftzufuhr | 0,6-0,8 Mpa (0,8m³/min) | 0,6-0,8 Mpa (0,8m³/min) |

| Gesamtleistung | 18kw | 22kw |

| Maschine Gewicht | 4200kg | 5200kg |

| Größe der Maschine (LWH) | 4500x3000x1900mm | 4500x3300x1900mm |

| Maschinenleistung | 5Linien 3 Phase 220/380/440V 50/60HZ | 5Linien 3 Phase 220/380/440V 50/60HZ |

KETE KTSM-C300 Serie

Die ideale Ausgangsbasis für effizientes Schneiden - KETE KTSM-C300 Serie. Für alle, die ein Upgrade auf eine Hochgeschwindigkeits-Schneidemaschine erwägen oder eine Geschwindigkeit von 300 m/min benötigen, stellt die KTSM-C300 Serie eine wirtschaftlich attraktive Einstiegslösung dar. Sie ist auf die Verarbeitung von flexiblen Verpackungen spezialisiert. Der maximale Rollendurchmesser beträgt standardmäßig Φ600mm beim Abwickeln und Φ450mm beim Aufwickeln. Es werden bewährte Rasierklingenschneid- und gesteuerte Differentialwellen-Aufwickelsysteme eingesetzt, die einen wirtschaftlichen und qualitativ hochwertigen Schnitt ermöglichen. So können Sie eine intelligente Anfangsinvestition tätigen, um eine effizientere Produktionssteigerung zu erzielen.

| Technische Daten der Maschine | Modell KTSM-C300/ 1100 | Modell KTSM-C300/ 1300 |

| Struktur der Rückspulung | Duplex-Rückspulung | Duplex-Rückspulung |

| Max. Breite des Rohmaterials | 1000mm (39.4") | 1200mm (47.2") |

| Max. Abwickeldurchmesser | Φ600mm (23,6") | Φ600mm (23,6") |

| Max. Aufwickel-Durchmesser | Φ450mm (17,7") | Φ450mm (17,7") |

| Min. Schlitzbreite | 50mm (1.97") | 50mm (1.97") |

| Max. Mechanische Geschwindigkeit | 300m/min | 300m/min |

| Papierkern Innendurchmesser | 76mm/152mm (3"/6") | 76mm/152mm (3"/6") |

| Schlitztechniken | Rasierklinge in der Luft | Rasierklinge in der Luft |

| Entfernen der Trimmung | Gebläse | Gebläse |

| Luftzufuhr | 0,6-0,8 Mpa (0,8m³/min) | 0,6-0,8 Mpa (0,8m³/min) |

| Gesamtleistung | 12kw | 15kw |

| Maschine Gewicht | 3800kg | 4000kg |

| Größe der Maschine (LWH) | 2200x4000x2100mm | 2200x4300x2100mm |

| Maschinenleistung | 5Linien 3 Phase 220/380/440V 50/60HZ | 5Linien 3 Phase 220/380/440V 50/60HZ |

NISHIMURA FH105E

Als eine weitere bemerkenswerte Maschine auf dem Markt bietet die NISHIMURA FH105E eine professionelle Schneidlösung für spezielle flexible Folien und laminierte Materialien. Sie bietet eine stabile Geschwindigkeit von 350 m/min und kann Rollen mit Φ800 mm Abwickel- und Φ500 mm Aufwickeldurchmesser verarbeiten. Die einzigartige horizontale Bewegung des Aufwickelständers, eine Auswahl von bis zu drei flexiblen Schneidmethoden (einschließlich verschiedener Rasier- und Scherschnitte) und ein präziser Kantenwickler, der die Qualität der fertigen Rollenkante verbessert, machen die Maschine zu einer leistungsstarken Alternative für professionelle und spezifische Anwendungen, die besondere Betriebseigenschaften und hohe Schnittpräzision erfordern. Sie nutzt die Friktionswellen-Aufwickeltechnik für eine genaue Spannungssteuerung.

| Spezifikation der Maschine | Spezifikation |

| Breite des Materials | Max. 1400 mm |

| Durchmesser der Rückspulung | Max. φ500 mm |

| Aufwickelwelle OD | φ3 Zoll (φ6 Zoll) |

| Schlitzbreite | Min. 80 mm |

| Geschwindigkeit der Maschine | 350 m/min. |

| Durchmesser abwickeln | φ800 mm |

| Schnittverfahren | Rasiermesserschneiden in der Luft, Rasiermesserschneiden im Wickel, Scherenschneiden im Wickel |

| Verfahren zum Aufwickeln | Umspulen mit Friktionsschächten |

Bewährte Praktiken für den Betrieb von Folienschneidmaschinen

Die Anschaffung einer Schneidmaschine, die hohe Leistungen erbringt, ist eine absolute Notwendigkeit; ihre langfristige Leistung - und ihr Wert - hängt jedoch von der richtigen Nutzung und der konsequenten Wartung ab. Um spürbare Produktionssteigerungen durch den effektiven Einsatz der Ausrüstung zu erzielen, müssen die Betriebsleiter und Maschinenbediener eine Reihe optimaler Praxisgrundsätze verstehen und anwenden:

- Gründliche Überprüfungen vor dem Betrieb: Führen Sie bei jeder Inbetriebnahme der Maschine eine systematische Prüfung durch. Vergewissern Sie sich, dass alles in Ordnung ist: alle Messer sind sauber, präzise befestigt und scharf, die Getriebekomponenten sind geschmiert, und alle Sensoren und Sicherheitsvorrichtungen funktionieren. Achten Sie genau auf die Qualität der Jumbo-Rollen im Hinblick auf ihre Spezifikationen und ihren Zustand.

- Einstellen und Anpassen von Parametern: Einstellen und Anpassen von Parametern: Definieren und verändern Sie die Abwickelspannung, die Schnittbreite, die Aufwickelspannung, die Geschwindigkeit und andere Parameter unter Berücksichtigung der Konstruktion der Abwickelrolle und der gewünschten Qualität der fertigen Rolle. Wissen, wie man kleine Änderungen während des Prozesses vornimmt, um eine bessere Präzision in Abhängigkeit von Material und Maschinenleistung zu erreichen. Die Einstellung dieser Parameter mit der gleichen Sorgfalt wie das Skalpell eines Chirurgen" ist entscheidend, um die gewünschte Endqualität zu erreichen.

- Bahneinfädelung und Bahnführung: Die korrekte Bahnführung durch die Maschine ist entscheidend. Stellen Sie sicher, dass das Material den richtigen Weg über die Umlenkrollen und durch die Spannzonen und den Schneidbereich nimmt. Falsches Einfädeln kann zu Falten, Bahnrissen oder schlechter Schnittqualität führen.

- Überwachung des laufenden Prozesses: Während die Maschine mit höchster Geschwindigkeit läuft, müssen die Bediener wachsam und aufmerksam sein. Beobachten Sie kontinuierlich die Bewegung der Bahn, die Spannungsstabilität, die Schnittkanten auf Grate, Delaminationen, Schmelzen sowie die teleskopierten Rollen - sind sie bereits vollständig geformt? Selbst bei diesen Kontrollen müssen Sie proaktiv sein, um Unregelmäßigkeiten zu erkennen und größere Verluste zu vermeiden.

- Handhabung von Schnittabfällen: Eine effiziente Entfernung und Handhabung von Schnittabfällen ist für einen kontinuierlichen Betrieb und die Aufrechterhaltung einer sauberen Arbeitsumgebung unerlässlich. Stellen Sie sicher, dass das System zur Beseitigung von Schnittabfällen (z. B. Gebläse oder Aufwickler) ordnungsgemäß funktioniert.

- Wissenschaftlicher Wartungsplan: Halten Sie sich bei der vorbeugenden Wartung strikt an das Wartungshandbuch des Herstellers. Dazu gehören die regelmäßige Reinigung (insbesondere des Schneidbereichs und der Walzen), die Schmierung der wichtigsten Komponenten, die Überprüfung und das Festziehen der Verbindungen sowie die Kalibrierung der Sensoren und Steuersysteme. Der rechtzeitige Austausch oder das professionelle Schärfen von Messern ist für eine gleichbleibende Schnittqualität von größter Bedeutung.

- Umweltkontrolle: Für empfindliche Materialien ist ein sauberer, trockener Arbeitsplatz mit kontrollierter Temperatur und Luftfeuchtigkeit entscheidend. Verhindern Sie, dass Staub und Feuchtigkeit die Präzision der Maschinen und die Eigenschaften der Materialien beeinträchtigen.

Die effektive Einhaltung der besten Betriebsverfahren erhöht die Langlebigkeit der Anlagen, optimiert die Produktionseffizienz und sorgt für eine hohe Produktqualität, was Ihre Investition rechtfertigt.

Ein vertrauenswürdiger Partner garantiert eine umfassende Unterstützung

Die Wahl einer Schneidemaschine ist wie die Wahl eines Geschäftspartners, da man auf eine sorgfältige Unterstützung achten muss. Wenn Sie sich für den Kauf wichtiger Produktionsmittel entscheiden, ist die Leistung der Maschine, die mit der Ausrüstung zu tun hat, zusammen mit dem Supportsystem des Unternehmens von Bedeutung. Da wir den Begriff "Seelenfrieden" verwenden, beziehen wir uns auch auf die Zusammenarbeit mit fachlich geschulten, serviceorientierten Lieferanten. Diese Lieferanten tragen dazu bei, langfristig zufriedene Ergebnisse zu erzielen.

Wir sind Ihr zuverlässiger Verbündeter bei der Geschäftsexpansion mit fast 40 Jahren Erfahrung in der Branche und robusten Fertigungskapazitäten mit einem jährlichen Verkauf von über 2000 Einheiten und Präsenz in mehr als 80 Ländern. Um Ihre Interessen zu wahren, halten wir uns strikt an Qualitätsstandards (ISO 9001, CE-zertifiziert, Verwendung weltweit anerkannter Komponenten, mehrfache Qualitätskontrollen), die beweisen, dass unsere Maschinen eine hervorragende Leistung und einen stabilen Betrieb gewährleisten. Von der Beratung vor dem Verkauf bis hin zum Kundendienst, der schnelle Fernhilfe, Engineering vor Ort, Lieferung von Ersatzteilen und System-Upgrades umfasst. Mit diesen allumfassenden Garantien sind Sie für die Produktion bestens gerüstet.

Wir halten die Werte Qualitätsbewusstsein, Kundenorientierung, Innovationsorientierung, Nachhaltigkeit und Ehrlichkeit hoch und streben danach, der vertrauenswürdigste Partner für Ihr Unternehmenswachstum zu sein.

Schlussfolgerung

Jede geschäftliche Entscheidung in Bezug auf Folienschneidmaschinen ist eine eigene Strategie. Die Bewertung der Rohstoffe, des gewünschten Outputs, der Qualitätsstandards, des Budgets und des erforderlichen Automatisierungsgrads führt zu einer genaueren Auswahl der Ausrüstung, die auf die Prozesse abgestimmt ist und den Produktionsnutzen optimiert. Jedes dieser Segmente hat unterschiedliche Bedürfnisse, und auf dem Markt gibt es viele ausgezeichnete Angebote.

Mit günstigen Preisen und vollautomatischen Lösungen kann jeder Bedarf gedeckt werden. Ein automatisiertes Kontrollsystem erhöht die Zuverlässigkeit erheblich und minimiert gleichzeitig die betrieblichen Eingriffe. Dies führt zu einem mühelosen Betrieb und kann mit wenig Aufsicht durchgeführt werden. Großartige Lösungen bieten auch Qualitätsgeräte mit unübertroffener Zuverlässigkeit und einem guten Ruf.

Die Stärkung der Wettbewerbsfähigkeit Ihres Unternehmens und das Erreichen eines kontinuierlichen Erfolgs kann nur durch einen strategischen Partner erreicht werden. Lassen Sie sich bei der Erreichung Ihrer Ziele von der Folienschneidetechnik unterstützen und erleben Sie einen reibungslosen Betrieb mit reduzierten Ausfallzeiten, während der vertrauenswürdige Partner gleichzeitig dafür sorgt, dass die Herausforderungen bewältigt und die operative Exzellenz erreicht wird. Beginnen Sie eine neue Phase des rationellen Schneidens mit vertrauenswürdigen Partnern und erschließen Sie sich noch heute ein sicheres Wachstum.