For businesses engaged in packaging, labeling, or dealing with flexible materials, acquiring a flexographic printing machine is a significant investment. The price of flexo presses varies with each machine’s parts, technology, servicing level, and more. Quite often, prospective buyers ponder whether to invest in new or used machines. This choice affects the balance between upfront capital and operating value, as well as returns generated later. Insightful decisions can only be made when the budgetary strategies revolving around flexo printing machines are well understood. The goal of this text is to define the cost components and aid in assessing alternatives to improve the investment strategy.

Flexo Printing Machine Types & Price Ranges

With flexo printing technology, it is possible to print on a variety of substrates, even a wide variety of substrates. Thus, multiple sorts of flexo machines exist—each designed for particular tasks and production volumes. As a result, the price varies greatly depending on the machine’s capabilities and structure. Here is a general overview of common flexo presses and their estimated prices. Keep in mind that these are only suggestions. Actual prices may vary based on the printing machine manufacturer, specific components, and market conditions.

| Loại máy | Sự miêu tả | Typical Uses | Rough New Price Range (USD) | Rough Used Price Range (USD) |

| Loại ngăn xếp | Printing parts are put one on top of the other. Simple design, lower price. | Paper bags, sacks, some flexible packaging. | $20,000 – $150,000 | $5,000 – $70,000 |

| Inline | Printing parts are in a straight line. Easy to add other steps. | Labels, paper boxes, flexible packaging. | $80,000 – $500,000+ | $30,000 – $250,000+ |

| Central Impression (CI) | Printing parts are around a big central roller. Prints colors very accurately. | Flexible packaging films, high-quality labels. | $200,000 – $1,000,000+ | $80,000 – $500,000+ |

| Narrow Web | Material width is usually less than 20 inches (500mm). Often inline type. | Label printing, flexible packaging, shrink sleeves. | $50,000 – $400,000+ | $20,000 – $200,000+ |

| Mid Web | Material width is usually between 20-40 inches (500-1000mm). Inline or CI. | Flexible packaging, paper boxes. | $150,000 – $800,000+ | $60,000 – $400,000+ |

| Wide Web | Material width is usually more than 40 inches (1000mm). Often CI type. | Flexible packaging films, layered materials, bags for industry. | $500,000 – $2,000,000+ | $200,000 – $1,000,000+ |

You decide on the type according to the materials you will print on, required print quality, estimated volume, and whether you need other processes integrated into the machine. A business printing basic patterns on paper bags may find a stack type machine sufficient and affordable. But for a company manufacturing opaque flexible pouches for food with high-end graphics, a CI machine would most probably be required since it prints in colors excellently.

Factors Affecting Flexo Printing Machine Price

Besides the main machine type, the final flexo printing machine price varies because of many factors. Knowing these factors helps you understand prices and compare different machines well.

Machine Type & Build

The choice of configuration type- stack, inline, or CI- has a significant effect on pricing. CI machines are the most expensive as they require more elaborate construction to achieve precision. Inline machines have more flexibility but become more expensive with the addition of features. Stack machines are basic and the cheapest. A machine’s durability coupled with its construction and part quality will also affect the price of the flexo press.

Number of Colors Matters

An increase in colors leads to the machine becoming more sophisticated and needing more components, thus increasing the price. As for the number of colors, it should correspond to the printing jobs you have.

Printing Width & Speed

The cost of wider machines is the result of greater strength and size. More powerful and faster machines also require precise control and improved drying; therefore increasing the price. Select machine width and speed based on required production volume.

Tự động hóa & Kiểm soát

The prices of smart controls and machines with advanced automation features, such as an AI-based smart control system, are usually higher. More advanced automation speeds up and simplifies production, while the smart parts and sophisticated control systems raise the unit price.

Drying System Options

The type and power of the drying system impacts pricing. Hot air and IR systems, although expensive, are cheaper than UV and EB drying systems. There is a trade off between speed and the ink type used in the machine.

Brand and Manufacturer

Well-known brands with years of experience usually cost more but offer better quality, reliability, support, and parts. Newer manufacturers might offer lower prices but need careful checking for their machine and service.

Customization Features

Adding special features or making changes to a standard machine will increase the price and delivery time.

Your Flexo Printing Machine Buying Guide: Costs and Choices

Deciding which flexo printing machine to buy is not an easy job. You need to think carefully about cost, what you need, and your long-term goals.

Assessing Your Needs

Before you start looking for a machine, you must clearly know what you need to print. This includes:

- Loại vật liệu: What materials will you mainly print on? (Paper, film, cardboard, non-woven fabric, etc.) How these materials affect which type of machine you should choose.

- Products to Print: What products will you make? (Labels, flexible packaging bags, paper boxes, paper cups, etc.) Different products need different machine parts and added features.

- Color Needs: How many colors do your products usually need? Do you need special colors or inks?

- Production Amount Needed: How much do you expect to produce each day or year? This tells you the printing speed and width you need.

- Print Quality Needed: How high is the print quality your customers need? (How well colors match, how clear small dots are, color richness, etc.)

- Ngân sách: How much money do you have to spend at first?

Knowing exactly what you need will help you find the right machines and avoid buying one that does too much or too little.

Initial vs. Total Ownership Cost

The majority of customers focus solely on the initial price of a machine. This, however, is the most superficial consideration. In fact, and as it relates to a flexo printing machine, its TCO or Total Cost of Ownership is more important. This encompasses:

- Initial Purchase Cost: The price of the machine itself, shipping cost, cost to set it up and test it, cost for training.

- Operating Costs: Cost of ink, printing plates, anilox rollers, doctor blades, tape, and other things you use up. Cost of electricity and labor.

- BẢO TRÌ Chi phí: Cost for regular checks and care, cost to replace parts, cost for unexpected repairs.

- Downtime Costs: Money lost because the machine is not working due to problems.

- Other Costs: Insurance, taxes, and maybe costs to upgrade or get rid of the machine later.

A machine that seems cheap at first may actually incur high costs in repairs, maintenance, and even internal parts. The total cost of ownership (TCO) of such a machine is likely to far exceed that of an initial expensive purchase. Evaluating TCO lets you make more intelligent and future-ready decisions.

New vs. Used Machines: Which Is Better for Your Budget?

This is a question many companies think about when they do not have a lot of money. Both new and used machines have good and bad points:

New Machines:

- Good points: Latest technology, work faster, more steady and reliable, last longer, come with warranty and support from the maker, parts are easy to get, usually meet newer rules for environment and safety.

- Bad points: Cost a lot at first.

Used Machines:

- Good points: Cost much less at first. You can get a machine that was high-end for a lower price.

- Bad points: Technology might be old, might have wear and tear and possible problems, might not have support from the maker, parts might be hard to find or cost a lot, might cost more to fix, might use more energy, might not meet the newest environment or safety rules. Buying a used machine is like sailing in unknown waters. There are both risks and chances.

For businesses that are just starting out or have very little cash, purchasing a second-hand machine might help get things going. As for businesses that need constant high quality production, cutting edge technology and a long term printer investment, having a new machine is always the go-to option. When purchasing a second hand machine, ensure a professional evaluates it fully. Also check repair history, warranty duration, and remaining service life.

Key Questions to Ask Before Investing in a Flexo Machine

When you talk to a seller, besides the price, be sure to ask these important questions:

- What materials and products is this machine best for printing?

- What is its real highest steady printing speed? (Not just the speed on paper)

- How well can it match colors?

- How well does the drying system work? How fast can it go?

- How much energy does the machine use?

- What automatic features does it have?

- How long is the warranty? What does the warranty cover?

- What is the after-sale service like? Do they help with setting up and training?

- Are parts easy to get? How much do they cost?

- Can the machine be upgraded with new technology later?

- Can I see examples of what it prints or talk to other users?

- How long will it take to deliver the machine?

These questions will help you learn about how the machine works, its possible costs later, and what support the seller gives.

Maximize Your Flexo Printing Machine Investment: Key Tips

Buying a flexo printing machine is just the first step. To get the most out of it and make the most money, you need good management and ongoing work:

- Operator Training: Make sure the people who run the machine are well trained. They should know how to use, care for, and fix problems with the machine. Good operators make production faster, waste less, and do not damage the machine.

- Regular BẢO TRÌ: Follow the maker’s advice for daily and regular checks and care. Like taking care of a high-performance race car, regular “check-ups” and care are key to keeping the machine in top condition and making it last longer.

- Improve Production Process: Look at and make the whole process. This includes getting ready before printing, putting material on, printing, and after-printing steps. This helps reduce time when changing jobs and waste.

- Choose the Right Supplies: Use good quality ink, printing plates, anilox rollers, and other supplies that work well with the machine. Good supplies help print quality and reduce wear on the machine.

- Watch and Understand Data: Use the machine’s control system to get data about production (like speed, amount produced, time stopped, waste amount). Look at the data to find problems and ways to make things better.

- Keep Learning and Improving: Watch for new technology and trends in the industry. Think about upgrading the machine if needed to stay competitive.

Investing in a New Flexo Printing Machine: Preparing for the Future

The decision to invest in a new flexo printing machine goes beyond the mere purchase of promotional equipment; it lays the foundation of your company’s future. Purchases of equipment nowadays come with the latest automatic features. This allows for high-speed operation, energy efficiency, steady printing, and minimal mechanical problems. All these factors enable a company to accept higher order volumes, meet more stringent quality standards, and adapt to dynamic changes in the industry.

Buying a new machine also means getting full support from the maker. This includes setting up, training, warranty, and ongoing technical help. This support is like a lighthouse guiding a ship. It shows the way and provides safety for your company’s production. Even though it costs more at first, in the long run, a new machine helps you work faster, saves money, makes better products, and makes you stronger in the market. These things often bring good returns on your investment. It lets your company plan for the future with more trust. You can try new things and take chances in the market.

KETE: Your Trusted Flexo Printing Machine Partner

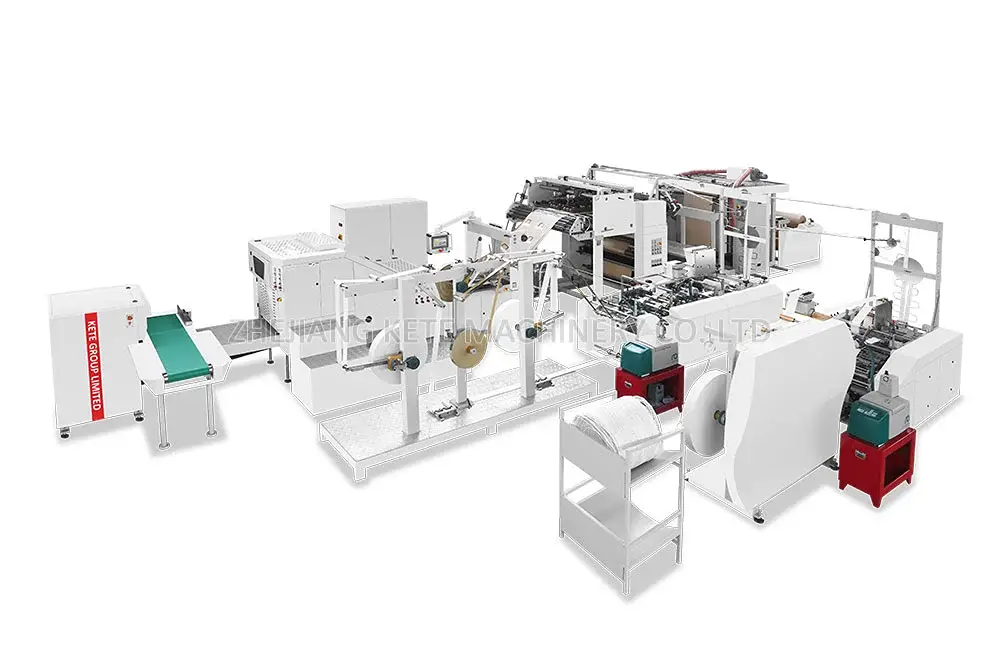

Choosing a dependable partner matters a lot. Founded in 2011, with more than 30 years of experience, KETE has operated in over 80 countries. We are a trusted partner for packaging firms and machinery vendors.

KETE understands that customers are concerned with pricing, machine operation, and reliability of the device. We have many production lines and collaborate with industry leading factories. Because of this, we have reliable machines and offer good prices. This ensures a strong foundation.

Our machines are capable of handling diverse materials and working at a steady high speed. From printing to bag making, all processes are completed internally. We comply with quality regulations and have earned certificates. We document every step of the process so you can trust us.

KETE gives full value. We offer custom machine setups and have experienced engineers. We help you choose the right machine and show you production progress. We pack and ship safely. We give a 1 to 2-year warranty and fast help after sale. We can send engineers if needed. We also have spare parts and online updates to keep machines working best.

By choosing KETE, you partner with a company that upholds the values of quality, customers, integrity, innovation, and foresight. We ensure you spend wisely and acquire quality machines at low prices. We can face a challenging future together.

Phần kết luận

The cost of a flexo printing machine is not straightforward. Factors such as type of machine, components, degree of automation, make, as well as new versus used, all play a role. Just considering the initial price may make you misinterpret the lifetime cost. Before making decisions, you need to determine priorities and requirements. Interpret the difference between the initial amount and the total expenditure over time. Consider thoroughly the pros and cons of both new and used machines.

Acquiring a flexo printing machine is a major advancement for a company. Such an investment is sure to pay off if it is well-researched, well thought out, and made with a trustworthy partner like KETE. It will strengthen the foundation of your company, enabling it to thrive and expand for decades. Take advantage of flexo printing technology to foster robust business growth.