Giới thiệu

The package is not a mere container in today’s competitive market. It is an experience. It is the initial point of contact, the silent salesman, and the protector of the consumer goods inside. The emergence of the global flexible packaging market is the most dramatic embodiment of this change of passive containment into active engagement. These soft, powerful materials have transformed various industries, whether it is the vacuum-packed bag that keeps our coffee fresh or the lightweight sachet that brings life-saving medicine.

This is a guide into that world. We shall break down the science of these materials, discuss their advantages, and follow them through the process of a plain roll of film to the finished product on the shelf.

What Are Flexible Packaging Materials

Flexible packaging is simply any package or container that is composed of flexible materials like non-rigid plastics. It is characterised by the fact that its shape can easily be altered when filled or in use.

This is in stark contrast with the so-called rigid product packaging, i.e., glass jars, metal cans, rigid plastic tubs, or cardboard product boxes. Where rigid packaging has its own structural support, flexible packaging depends on its contents, its design (such as a stand-up pouch), or an external structure (such as a bag-in-box) to support its form. Its slimmer shape enables it to fit the shape of the product, and it uses fewer raw materials compared to the traditional rigid ones.

The building blocks of this industry are the materials themselves. They are usually thin-gauge substrates that can be shaped, closed and printed. The most prevalent of these materials are a great variety of plastic films, engineered papers, and ultra-thin aluminum foils. In the vast majority of cases, one of these materials is not a final package, but a strategic assembly of them, designed to do a specific set of tasks.

Key Benefits of Flexible Packaging

Flexible packaging solutions are being adopted at a very high rate. It is the outcome of a clear and strong value proposition which is of benefit to the manufacturer, the retailer and the end consumer equally.

Deep Resource Efficiency: It is, perhaps, its greatest strength. Compared to rigid packaging, flexible packaging consumes significantly less material to produce. An example of this is a lightweight pouch with a thinner profile that can use 70 percent less plastic than a rigid bottle of the same volume. This decrease is directly translated into lower costs and a decrease in fuel used during transportation.

Excellent Product Protection and Shelf Life: The main role of any package is to ensure the protection of its contents. Plastic materials are good for this. They may be designed to have excellent barrier properties to provide a hermetic, micro-environment around the product. This helps preserve sensitive products against oxygen, moisture, UV light, and contaminants, which guarantees product freshness and minimizes food waste. This protective capability makes them the ideal flexible food packaging materials for modern supply chains.

Unparalleled Consumer Convenience: Flexible packaging is designed to suit the on-the-go lifestyle. Such innovations as resealable zippers, tear notches that can be easily opened, liquid pouring spouts, microwaveable and self-venting pouches are all products of this format. It is versatile, mobile, and a great solution to contemporary life.

Expansive Brand Real Estate: A jar or can with a rigid label provides a restricted label. A stand-up pouch has a high-definition, 360-degree canvas. With flexible packaging, it is possible to print brilliant, photorealistic images on the entire surface of the package. This provides the brand with a more professional presentation and an unmatched chance to get the attention of consumers and tell their story directly on the shelf.

Common Types of Flexible Packaging Materials

The world of flexible packaging is a world of combinations. Rarely is a single material utilized alone. Rather, engineers develop multi-layer laminates or co-extrusions in which each layer adds a desired property, such as strength, barrier, printability, or sealability. The key to the final package is to understand the main workhorse materials.

Primary Polymer Films: The Workhorses (PE, PP, PET)

These are the three polymers that constitute the industry.

PE (Polyethylene): PE is the most widespread plastic on earth and the ultimate sealant. It has a low melting point and is therefore suitable in the production of powerful and dependable heat seals. You will have it in two kinds:

LDPE (Polyetylen mật độ thấp): Soft, clear and very flexible. It is applied to common plastic bags, polyethylene bags, and even heavy-duty garbage bags. In manufacturing, stretch films are specific formulations that are used as a highly elastic material to hold pallets. Another type of LDPE that is used to provide protection is bubble wrap.

HDPE (High-Density Polyethylene): More solid, tougher and opaque. Applied to cereal box liners and other uses where a higher degree of stiffness is needed.

PP (Polypropylene): It is appreciated due to its stiffness, high moisture barrier, and high melting point.

BOPP (Biaxially Oriented Polypropylene): This is the film used for snack bags (chips, cookies) and candy wrappers film which is crisp and clear. It is bi-axially oriented (stretched in two directions), which makes it incredibly strong, clear and has a flawless surface to print on at high speed.

CPP (Cast Polypropylene): Softer than BOPP, and commonly applied as a heat-seal layer in retort (high-heat) applications. Sometimes reinforced with polypropylene fibers for specific industrial uses.

PET (Polyethylene Terephthalate): This is the main structural and print layer of the industry. PET is very strong, dimensionally stable (it does not stretch or shrink with changes in temperature) and offers a good oxygen barrier. It is also very thermally stable and can therefore resist the heat of the printing and laminating process without deforming, thus making it a perfect material for high-quality graphics.

High-Barrier Materials: The Protectors (Foil, EVOH, VMPET)

A standard polymer is not sufficient when the product is very sensitive to the environment (such as coffee, pharmaceuticals, or high-fat foods). It must be a high-barrier material.

AL (Aluminum Foil): Foil packaging is the absolute barrier. When it is thick enough, it is said to offer an ideal, hermetic seal against all oxygen, moisture, and light. It is the gold standard when it comes to products that need the longest shelf life possible like military rations, medical supplies, and premium coffee.

EVOH (Ethylene Vinyl Alcohol): It is a special barrier film material that has an incredible oxygen blocking capacity. It is normally co-extruded as a microscopic, ultra-thin layer within other polymers (such as PE or PP). It has only one weakness, moisture, which reduces its barrier properties, and therefore it should always be enclosed between other materials that shield it against the product and the external air.

VMPET (Vacuum Metalized PET): It is the reflective, glossy material that you find inside most snack packets. It is not foil. It is a PET film which has been vapor-deposited with a microscopically thin layer of aluminum in a vacuum. It offers a substantial enhancement of barrier properties – much better than PET alone – but is much less expensive and more flexible than actual aluminum foil. It also gives it a high-end, metallic appearance.

Paper and Bio-Based Materials: The Sustainable Choice

Sustainable substrates are a fast-emerging category in response to market demand.

Bài báo: Paper bags, decorative gift bags, and artisanal product wraps are made using materials such as Kraft paper, which has a tactile, natural look and feel that appeals to organic and artisanal brands. Paper is not very good at moisture and oxygen barrier, and thus in most food applications, it is laminated with a thin, inner layer of a polymer film (such as PE) to give it a functional barrier and, most importantly, a heat-sealable surface.

Bio-Based Polymers (PLA): PLA (Polylactic Acid) is the most widespread bio-polymer, which is made of renewable sources such as corn starch. It can be industrially composted, i.e., it can decompose under certain conditions of heat and moisture. Although a significant breakthrough, it currently has trade-offs: it is more fragile than conventional plastics and has worse barrier properties, so it is only applicable to short shelf life products such as fresh produce or cold-brew coffee.

| Vật liệu | Oxygen Barrier (OTR) | Moisture Barrier (WVTR) | Melting Point (~°C) | Recycling Code (RIC) | Relative Cost Index | Primary Function |

| Polyethylene mật độ thấp | Very Low (Breathable) | Trung bình | ~105 – 115°C | #4 (LDPE) | 💲 | Sealant Layer |

| Polyethylene mật độ cao (HDPE) | Thấp | Cao | ~130 – 135°C | #2 (HDPE) | 💲 | Stiffness / Liner |

| BOPP | Thấp | Cao | ~160 – 170°C | #5 (PP) | 💲💲 | Print Surface / Snack Web |

| CPP | Thấp | Trung bình | ~140 – 150°C | #5 (PP) | 💲💲 | Retort Sealant |

| PET | Trung bình | Trung bình | ~250 – 260°C | #1 (PET) | 💲💲💲 | Outer Structure / Print |

| Giấy bạc nhôm | Absolute (Zero) | Absolute (Zero) | > 600°C (Non-sealable) | N/A (Metal) | 💲💲💲💲💲 | Ultimate Barrier |

| VMPET | Cao | Cao | ~250°C | #1 (PET)* | 💲💲💲 | Cost-Effective Barrier |

| EVOH | Ultra-High | Low (Sensitive to humidity) | ~160 – 180°C | #7 (Other) | 💲💲💲💲 | Gas Barrier Layer |

| Giấy Kraft | None (Porous) | None (Absorbent) | N/A (Burns) | #20 (PAP) | 💲💲 | Aesthetics / Artisanal |

| PLA | Trung bình | Thấp | ~150 – 160°C | #7 (PLA) | 💲💲💲💲 | Compostable Option |

Key Properties to Consider When Selecting Flexible Packaging Materials

The selection of a material is a technical process of aligning the requirements of a product with the data sheet of a material. Engineers are concerned with certain material properties:

Barrier Properties (OTR & WVTR): This is essential. Nuts and other food products require a low OTR to avoid rancidity and dry powders require a low WVTR to avoid clumping.

OTR (Oxygen Transmission Rate): This is a measure of the amount of oxygen that can be transferred through a film in 24 hours. A low OTR is required in a product such as nuts (high in oil) to avoid rancidity.

WVTR (Water Vapor Transmission Rate): This is a measure of the amount of moisture that can be passed through. A dry powder (flour, protein mix) product requires a low WVTR to avoid clumping.

Sealability: This is the property of a material to create a dependable connection with itself or another material under heat and pressure. The most important is the heat-seal window – the temperature at which an ideal seal is created. A broad window is lenient; a narrow window is hard and demands very fine machinery.

Độ bền: This is a physical toughness measure. It encompasses puncture resistance (important to sharp products such as bone-in meat or pasta) and flex-crack resistance (the capability of the material to be folded many times without pinholes, essential to stand-up pouches).

Printability: The surface energy of a material is what defines its ability to receive and retain printing inks. The surface energy of most polymer films is low and requires an electrical process known as corona treatment to make them ink-receptive.

Common Applications of Flexible Packaging Materials Across Industries

By mixing these materials and properties, you will be able to come up with a purpose-built package of various kinds of products.

Food & Beverage: The biggest sector is food packaging. When selecting flexible packaging materials for food products, common structural combinations include:

Snack Foods (Chips): BOPP (print and stiffness) + VMPET (barrier) + PE (sealing).

Coffee (Grounds/Beans): PET (print) + Aluminum Foil (absolute barrier) + PE (sealing) high-barrier laminate.

Liquid (Soup/Juice): A sturdy stand-up pouch, usually lined with nylon to prevent punctures and a spout to pour.

Perishable Food Items: High-barrier films are needed to keep meat and cheese safe for an extended shelf life.

Pet Food: Multi-wall bags are being substituted by heavy-duty pouches used in dog and cat food.

Pharmaceutical/Medical: This is a high-stakes sector that uses flexible packaging (blister packs- Foil/PVC) to preserve individual doses, and sterile-barrier packaging (medical devices) that must ensure sterility until the point of use.

Personal Care & Home: Detergent pods contain a special water-soluble film (PVA). The shampoo and conditioner are packaged in refill pouches that consume much less plastic compared to bottles. Sachets Cosmetic samples (sachets) offer a low-cost, hermetic-sealed single serving.

The Journey from Raw Film to Finished Pouch: Understanding the Converting Process

The materials that we have discussed do not just appear as complete pouches. They come to manufacturing plants in huge form of master rolls. The complex, fast-moving engineering operation that converts this raw film into shelf-ready packaging is referred to as Packaging Converting.

This change is usually carried out in four stages:

In ấn: Initially, Flexographic presses are used at high speed to print branding graphics, typically on the back of the outer film. The most important issue is to keep the color registration and tension constant to prevent the stretching and warping of thin films.

Laminate: The layers (PET, Foil, PE) are then bonded to form a composite layer that incorporates their characteristics such as strength, barrier protection and sealability. Here, it is important to apply a uniform adhesive to avoid delamination or failure of barriers.

Cắt dọc: This is followed by cutting the wide master roll into smaller product line-specific narrow rolls. Burr-free edges are essential to avoid jamming on downstream automated packaging lines.

Bag Making: The film is lastly folded, heat-sealed and cut into separate pouches. This step determines the integrity of the packages, and it is necessary to maintain a very specific temperature to guarantee the absence of leaks in the packages, particularly in formats that have zippers.

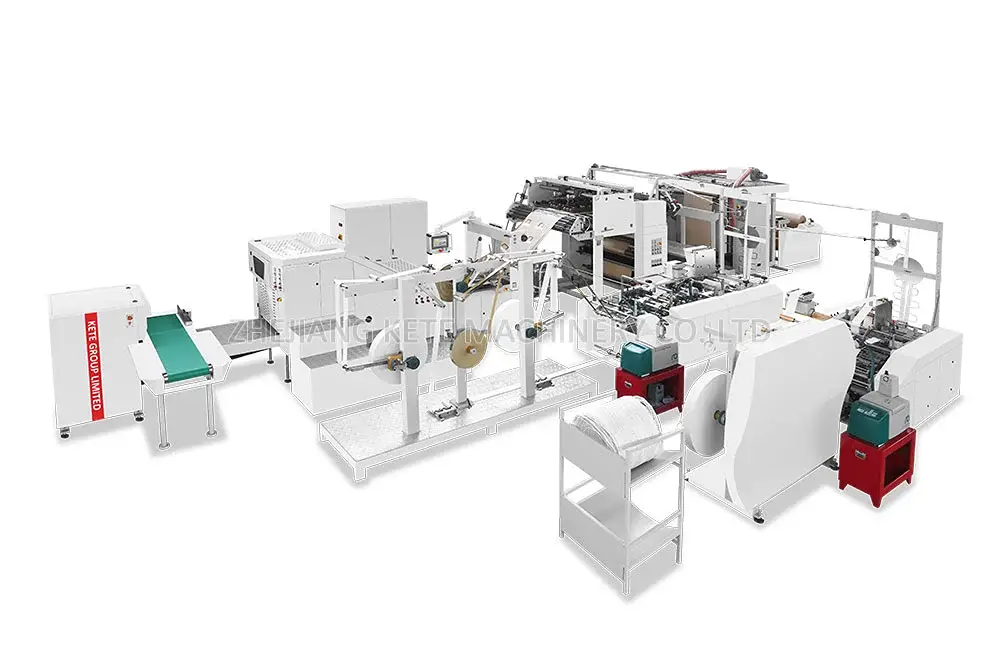

This process is where material potential meets physical reality. Even the finest high-barrier films are rendered useless if the machinery cannot maintain exact tension, temperature, and pressure. Your material investment is only as good as the equipment processing it. That is why navigating this complex conversion journey requires proven reliability. At KETE, we specialize in customized flexible printing and packaging converting machine solutions. Backed by 30+ years of manufacturing expertise and ISO 9001/CE certification, our “Quality First” commitment ensures your materials are processed with precision into flawless, profitable products.

Trends in Sustainable Flexible Packaging Materials

The sector is now undergoing a colossal transformation, which is caused by regulatory pressure and consumer demand for sustainability. This is the direction that material science is taking.

Mono-Materials: This is the most significant trend. A conventional laminate (PET/Foil/PE) is a nightmare in terms of recycling since the layers are not separable. The answer is to make packaging out of a single material, e.g., 100% Polyethylene structure. This renders the whole package to be recycled in one stream. The challenge? These new mono-materials are infamously hard to work with- they creep, twist, and possess very small heat-seal windows, which impose very high demands on the accuracy of the converting equipment.

PCR (Post-Consumer Recycled) Content: This is the step towards recycling plastic back into new flexible packaging. This forms a plastic circular economy.

Design for Recycling (DfR): This is a philosophy in which the end-of-life of the package is taken into account during the very initial design sketch. This implies the elimination of problematic inks, adhesives, or combinations of materials that pollute the recycling stream.

How to Choose the Right Material for Your Product

In this whole landscape in sight, the ultimate choice is reduced to a system of critical questions. No material is the best, just the right material for a certain application.

What is the main need of your product? Begin with the non-negotiables. Is the product a liquid that is aggressive? You require chemical resistance. Is it sensitive to oxygen? High-barrier materials such as Foil or EVOH must be your starting point in search.

What is your brand’s identity? What should the package look and feel like? Is it a high-gloss product (PET/VMPET) of high quality? Or is it an organic, crafted product (Paper-laminate)?

What is your sustainability objective? Is “recyclable” the key driver? Then you have to venture into mono-materials. Is “compostable” the goal? Then PLA is where you begin.

What is your reality of operation? This is the question that is most frequently overlooked. The decision to use a more advanced, recyclable mono-material should be made in tandem with your operations department and machinery suppliers. Your printing presses, laminators, and bag makers, must be able to deal with these unforgiving new substrates.

Phần kết luận

Flexible packaging materials are a dynamic and multifaceted science, a cross-section of material science, chemical engineering, and brand marketing. The mere pouch you are holding in your hand is the product of a thousand wise choices – a trade-off between barrier and cost, durability and sustainability, aesthetics and machine-readiness. It is not just a matter of a film but a matter of an integrated system. A system in which the material, the product, the needs of the consumer, and, most importantly, the machinery to transform it, should all be in perfect, high-speed harmony.

Câu hỏi thường gặp

Q:What are the 5 packaging materials?

In the specific context of the flexible packaging industry, the “big five” primary materials (substrates) used to construct laminates are:

Polyetylen (PE): The most common plastic, primarily used as the inner sealant layer because of its low melting point and durability.

Polypropylen (PP): Including BOPP and CPP. It is valued for its excellent clarity, stiffness, and heat resistance, often used for snack webs and printing layers.

Polyester (PET): A tough, heat-resistant material usually used as the outer structural layer. It provides high-quality printability and strength.

Aluminum Foil (AL): Used in high-end applications (like coffee or pharma) to provide an absolute barrier against moisture, oxygen, and light.

Polyamide (Nylon) or Paper:

Nylon is used for puncture resistance (e.g., bone-in meats).

Giấy Kraft is used to provide a natural, organic look and feel.

Q: What is GSM in flexible packaging?

GSM stands for “Grams per Square Meter.”

Definition: It is a metric used to measure the weight and density of the packaging material. It tells you how much one square meter of a specific film or laminate weighs in grams.

Why it matters:

Material Thickness & Quality: Generally, a higher GSM indicates a heavier, thicker, and more rigid material, while a lower GSM implies a lighter, thinner film.

Cost Calculation: Since raw flexible packaging film is often sold by weight (kg/ton), understanding the GSM is critical for calculating the “yield” (how many pouches can be produced from a roll) and the cost per unit.

Q: Are flexible packaging materials sustainable or recyclable?

The answer depends on the structure of the material:

Traditional Laminates: Historically, no. Most flexible packaging uses multi-layer laminates (e.g., PET bonded to Foil and PE). Because these layers are made of different materials that cannot be easily separated, they are difficult to recycle in standard facilities.

Mono-Materials (The Modern Trend):Yes. The industry is shifting toward “Mono-material” structures (e.g., All-PE or All-PP). Since these pouches are made from a single type of polymer, they can be recycled in existing plastic streams.

Bio-Based/Compostable: Materials like PLA (Polylactic Acid) or cellulose films are designed to be industrially compostable, offering a sustainable alternative for products with shorter shelf lives.