Giriş

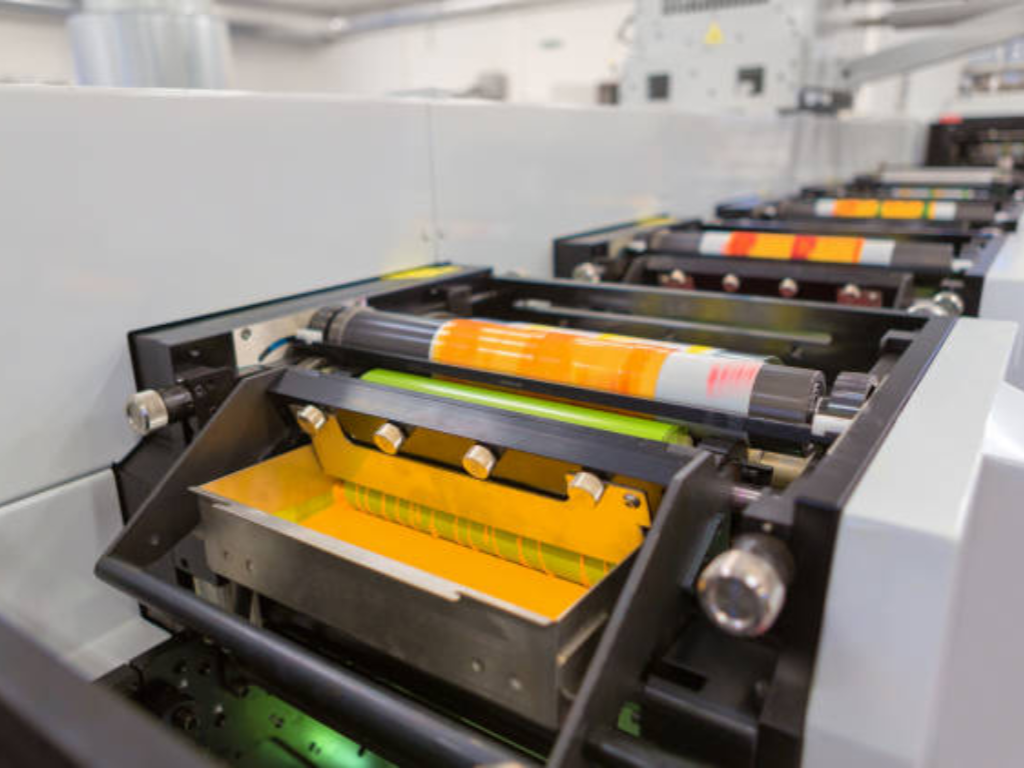

A 0.1mm of doctor blade wear in a high-velocity production setting can cut 10,000meters of packaging substrate, transforming potential profit into industrial waste. Precision in the modern environment of manufacturing is not only a dream but the foundation of economic sustainability. To maintain superior print quality and extend blade life, understanding the mechanical nuances is vital. In the high-speed conditions of flexographic printing process, and gravure printing, the printing doctor blade is the key mechanical contact point between the complicated fluid mechanics and the end substrate. This component is often ignored because of its seemingly simple look, but it is the final judge of the ink film thickness and, therefore, the aesthetic and functional integrity of the printed product.

With the growing pace of production and the increasing demands of brands on the absolute color consistency, the mastery of the technical peculiarities of the choice and implementation of printing doctor blades has become not only a marginal task but also a necessary skill of any competitive printing enterprise. This is particularly true when identifying the specific requirements for gravure doctor blades versus a doctor blade for flexo printing, especially when dealing with abrasive inks.

What is a Doctor Blade and Why Does It Matter in Printing

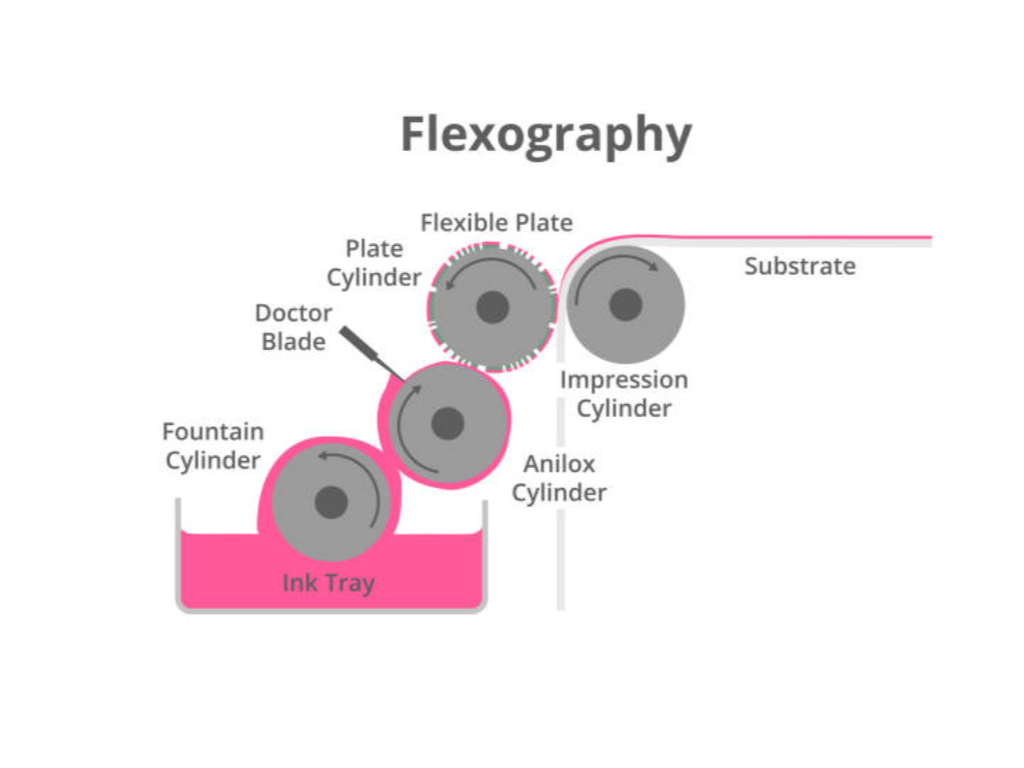

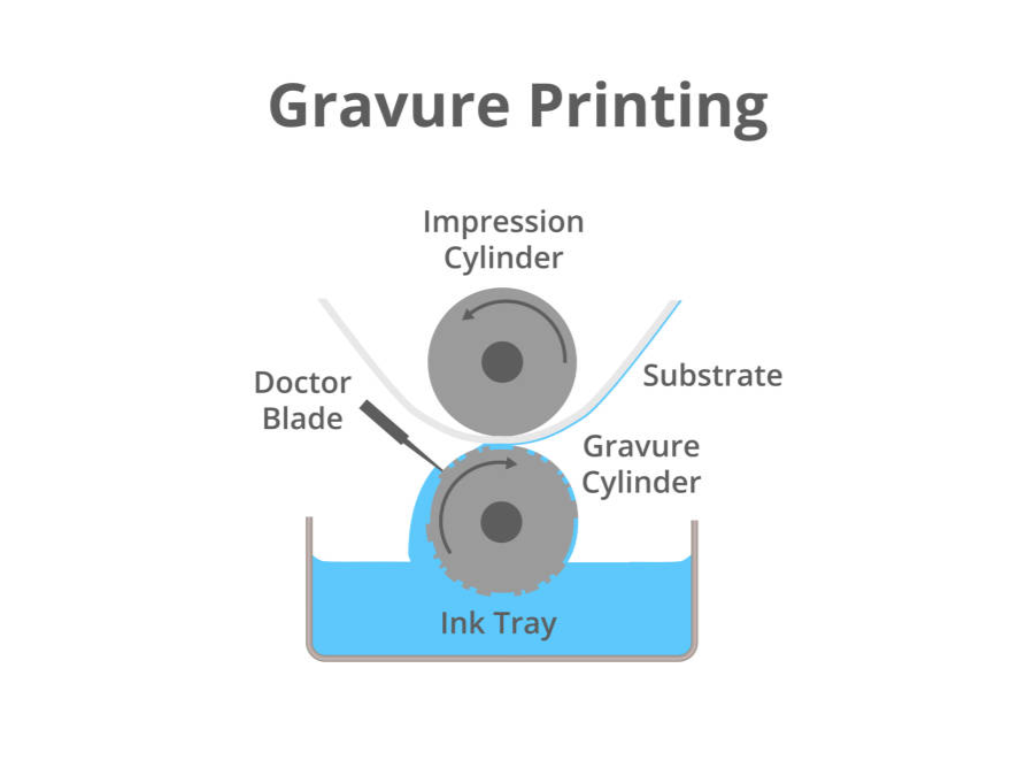

A doctor blade is a high-precision strip, usually made of steel or a plastic blade synthetic polymers, that is used to clean up excess ink on the smooth surface of a printing cylinder or the engraved cells of an anilox roller. Its main purpose is the metering, or the process of making sure that only a pre-established, accurate amount of ink is left in the engravings before it is transferred to the plate or substrate.

The significance of this element cannot be overestimated. The doctor blade in a flexographic system is a volumetric controller. In its absence, the transfer of ink would be uncontrollable, resulting in flooding, irregular densities, and total loss of tonal range. Economically, one of the main cost control levers is the doctor blade. Proper metering will save on the wastage of ink and also limit the number of rejects which are the silent profit killers in the packaging industry. In addition, the blade safeguards the most costly part of the press: the ceramic anilox roller or the engraved gravure cylinder. The blade selected or not properly maintained may result in permanent scoring caused by hard particles on these surfaces, which results in disastrous equipment breakdown and huge capital costs to replace them.

The Working Principle: How Doctor Blades Ensures Precision

The working efficiency of a doctor blade is based on the concept of mechanical wiping and fluid shear. Since the printing cylinder spins at high speeds, it transports excess ink from the fountain to the printing plate. To shear this excess, the doctor blade is set at a given contact angle, usually 30 to 35 degrees.

It is a fine balancing act of forces. On the one hand, there is the pneumatic or mechanical pressure on the blade to fix it on the cylinder. On the other side, there is the hydrodynamic lift of the ink film itself. The doctor blade is a watchful guardian at a fast crossing, and only a very precise quantity of ink is permitted to pass through its microscopic gate to ensure consistent ink transfer. When the pressure is insufficient, the blade will float on the ink film, and the effect is called spitting or hazing. Excessive pressure leads to a higher friction rate, which in turn leads to premature wear of the blade and the cylinder, and may produce sufficient heat to change the chemical viscosity of the ink. Accuracy is ensured by the stability of the blade holder and the uniformity of the blade footprint, or the real area of contact with the cylinder.

Understanding Common Types of Doctor Blades in Printing

Doctor blades are not homogeneous; they may be classified by their physical geometry and the mechanical systems in which they are contained.

Classification by Edge Profiles

The profile of the tip or edge of the blade defines its interaction with the ink and the surface of the cylinder as time goes on.

Lamella Type

The lamella tip is defined by a lower thickness at the contact edge. As an example, a new blade may have a base thickness of 0.20 mm and a lamella tip of 0.075 mm. The main benefit of this design is that the contact area does not change with the wear of the blade. In high-definition printing, where tonal consistency is of the utmost importance, the lamella blade is used to ensure that the footprint does not expand, and the ink density does not drift out of place during long production runs.

Bevel Type

A bevel edge is a sloping tip, typically ground at an angle of 2 to 15 degrees. The contact area of a bevel blade, unlike the lamella, grows with wear. The bevel profile is however much sturdier and works effectively in conjunction with a rotating anilox roller. It is used in applications where heavy ink loads are needed, abrasive pigments (white or metallic inks) are required, and where solid color areas are to be printed where tonal dots are not required to be microscopic but rather mechanical.

Rounded/Radius Type

A bevel edge is a sloping tip, typically ground at an angle of 2 to 15 degrees. The contact area of a bevel blade, unlike the lamella, grows with wear. The bevel profile is however much sturdier. It is used in applications where heavy ink loads are needed, abrasive pigments (white or metallic inks) are required, and where solid color areas are to be printed where tonal dots are not required to be microscopic but rather mechanical.

Classification by Blade Systems

The effectiveness of the blade is also dictated by the chamber or holder system in which it resides.

Single Blade Systems

In conventional open fountain systems, one doctor blade is employed, usually in a trailing or wiping position, to control the transfer of ink from an anilox roll. Single blade systems are cheap and easy to install, but they are prone to ink evaporation and environmental pollution. More complex configurations are replacing them in high-speed industrial applications.

Chambered Doctor Blade Systems

The contemporary gold standard is the chambered system, especially in flexography. It is made up of two blades, one of them being a metering blade and the other one a containment blade, which are enclosed in a closed chamber. This arrangement enables the constant pressurized flow of ink, eliminates the evaporation of solvent-based inks (and thereby preserves pH and viscosity), and greatly minimizes the amount of ink wasted while also reducing press downtime. The hydraulic stability required to eliminate ink spitting in high-speed operations is provided by the chambered system.

Exploring Doctor Blade Materials: Steel vs. Synthetic

The material selection is a compromise between accuracy, durability, and safety.

Carbon Steel is the standard in the industry. It is the hardest, and can be ground to very fine tolerances. Carbon steel gives the sharpest wipe when used in high-speed gravure or fine-screen flexo. Nevertheless, it can easily be corroded when it is used with water-based inks.

Paslanmaz Çelik solves the corrosion problem and thus it is the standard of flexographic printing using water. Although a little softer than carbon steel, it does not allow the development of rust, which would otherwise become an abrasive and destroy the anilox roller.

Plastic/Synthetic Blades (Polyester or UHMW) have become very popular. Their main value proposition is that they are safe, they do not form the razor-sharp edges that worn steel blades form, and the operator is less likely to be injured. Moreover, they are much more lenient on the anilox roller. Although they cannot match the fine metering accuracy of steel in high-lpi (lines per inch) work, they are good in corrugated printing, coatings and large-format solids.

Ceramic Coated Blades are the highest quality. Manufacturers produce a blade by placing a microscopic layer of ceramic over a steel base, which is a combination of the accuracy of steel and a life span that may be 3 to 5 times longer. This is an investment in lessening the downtime since the less the blade changes the more the hours of active production.

Strategic Selection: Matching Doctor Blades to Your Process

The choice is not a subjective one, but a multi-variant optimization problem in which the mechanical characteristics of the blade and the ink type have to match the kinetic energy of the press, especially in flexo printing applications. Four main technical vectors should be considered in order to reach the balance in the pressroom:

Press Type: Flexo, Gravure, and Offset

The spring requirement of the blade, including blade thickness, is determined by the mechanical interface. In Flexo, the emphasis is on the safety of the ceramic anilox; a blade with a 0.15mm base and 0.075mm lamella is the norm in high-lpi work to avoid scoring. In Gravure, attention is given to the surface area of the chrome cylinder; a heavier 0.20mm blade is used to give the required rigidity to avoid hazing over broad webs. In coating units or ink duct metering, offset printing needs blades with high dimensional stability to maintain uniformity of the varnish without the profile being warped by thermal expansion.

Ink Chemistry and Oxidation Resistance

Ink is a reactive chemical substance. Inks based on water need at least 13 percent of chromium in stainless steel to avoid microscopic oxidation along the metering edge. UV inks, which are prone to uv ink spitting, have high tack and viscosity, which creates a lot of friction. In response to this, hardened long-life coating is suggested to reduce heat accumulation and maintain edge integrity against the aggressive resins of modern UV formulations.

Production Speed and Hydrodynamic Force

Velocity makes ink a structural force. The ink forms a hydrodynamic wedge at speeds greater than > 300 m/min and tries to lift the blade off the roller- a similar effect to aquaplaning. The blade should be very stiff at the tip to overcome this hydraulic lift in order to have a clean wipe at high velocities. The blade should be a sharp hull that stays on course in a heavy swell, and is not affected by the pressure which would otherwise cause it to spit ink or hazard.

The Anilox-to-Tip Ratio

The correlation between the Lamella thickness and the Anilox Line Screen (LPI) is the most practical measure to use in the selection. In the case of a 1000 LPI roller, the walls of the cell with edge shape are microscopic. When the tip of your blade is excessively thin, it can dip into the cells, resulting in dot gain or color imbalance. Professional thumb rule: the thickness of the blade tip must be about twice the width of the anilox cell wall to make sure that it does not mechanically interfere with the cells.

To have a quick technical reference, the following table is a summary of the engineering standards that are needed to ensure the best synchronization of your doctor blade and the press system, thereby preventing material waste:

| Değişken | Engineering Benchmark | Technical Objective | Impact of Deviation |

| Flexo Contact Angle | 30° – 35° | Ensure clean shearing geometry | Anilox scoring or ink spitting |

| Gravure Linear Pressure | 1.5 – 3.0 kg/cm | Clear ink from non-image areas | Hazing or excessive blade wear |

| Water-based Ink Chemistry | pH 8.5 – 9.5 | Prevent chemical destabilization | Micro-pitting and corrosion |

| UV Ink Viscosity | High / Non-Newtonian | Shear through high-tack resins | Blade floating and density drift |

| High-Speed Threshold | > 300 m/min | Counteract hydrodynamic lift | Aquaplaning and ink leakage |

| Anilox Wall-to-Tip Ratio | 4 – 6 μm (@ 1200 LPI) / 2:1 Rule | Protect cell wall integrity | Anilox peak fracturing |

Troubleshooting and Maintenance: Solving Common Printing Defects

The finest doctor blade will not work well when it is not maintained.

The most prevalent defects are Streaks and Lines. They are typically brought about by hanger- small pieces of dried ink or substrate debris that get stuck between the blade and the cylinder. The main defenses are regular cleaning of the chamber and use of ink filters.

Ink Spitting is a common occurrence in flexography using UV inks. It happens when the ink accumulates behind the blade and is thrown onto the web centrifugally. The remedy is usually to change to a stiffer profile lamella blade or to add damping to the chamber system.

Chatter Marks are horizontal bars of irregular color on the web. This is due to the vibration of the blades. It can be corrected by changing the angle of contact, decreasing the pressure of the blade, or inspecting the bearings of the machine.

The maintenance should be in accordance with a Strict Operating Procedure (SOP). Before installation, blades are to be checked for the presence of burrs. The blade holder should be exactly parallel to the cylinder; the slightest misalignment of 0.1 mm will result in uneven wear and color changes. A surgeon needs a sterilized scalpel just as a machine operator needs to treat the doctor blade like a clean scalpel, because even a microscopic nick can be seen as a visible defect on thousands of meters of substrate.

Why Choose KETE Printing Machines

For organizations seeking to bridge the gap between theoretical precision and practical production, the equipment manufacturer’s engineering philosophy is the deciding factor. KETE approaches doctor blade integration not as an afterthought, but as a core system component.

In our KTFP-S200P Series high-speed flexo presses, we implement a Double-Side Enclosed Type Doctor Blade system. This design does more than just hold a blade; it creates a pressurized environment that stabilizes ink flow and eliminates the “float” associated with high-speed production. By pairing this with high-grade Ceramic Anilox Rollers, KETE ensures that the metering process is as frictionless as possible, extending the lifespan of both the consumables and the rollers.

In the realm of Gravure, KETE’s KTMS-C Series features a Pneumatic Type Design for the optimum doctor blade assembly. Unlike manual adjustment systems, our pneumatic controls provide a perfectly uniform pressure across the entire width of the cylinder, compensating automatically for microscopic variations. Furthermore, our blades are controlled by Separate Motors for the oscillation movement. This independent motion ensures that the blade is constantly shifting, preventing debris from settling and virtually eliminating the “streaks” that plague inferior machines.

When you choose KETE, you invest in a printing machine where the stability of the frame and the precision of the blade system work in perfect engineering synergy.

Sonuç

The doctor blade is an industrial compromise masterpiece, striking a balance between hardness and flexibility and cost and performance. To the contemporary printer, the way to better quality is in the careful choice of blade profiles and tip configurations and materials, specific to the chemistry of their inks and the speed of their presses. But as we have seen, the best blade is only as good as the machine that carries it.

With the knowledge of the symbiotic relationship between the metering tool and the printing press speed, manufacturers can attain the holy grail of production: high-speed quality with minimal waste. At KETE, we are committed to delivering the mechanical stability and innovative design to make that precision a reality in everyday life.