การแนะนำ

In the competitive industrial printing process, accuracy is not an objective; it is the minimum condition of profitability. Whether in digital printing, offset printing, or large-scale flexography, accuracy is paramount. Misregistration, or the inability of color separations to match exactly on a substrate, is one of the most intractable and expensive misregistration challenges of flexographic and rotogravure processes today. It is the mute robber of the pressroom, who converts high-quality raw materials into waste and production hours into idleness. A single millimeter off the cyan plate and the magenta, and the image becomes indistinct, and the brand owner will lose trust in the converter.

This blog breaks down the mechanics of registration failure, going beyond the symptoms on the surface to get to the underlying causes in the machinery, materials, and methodology. With the knowledge of the physics behind print wanders, operators and managers can put in place systemic solutions that protect quality and the bottom line.

What is Print Misregistration and Why Does It Matter

In its simplest form, print registration is the accurate overprinting of several layers of colors to create a unified image. In flexography and gravure, where the CMYK color model (and spot colors) are used, the press has to deposit each ink film precisely in alignment with the other. When this coordination is not achieved, misregistration issues take place.

The visual testimony is indisputable. It appears as a blurring of the printed image, where what should be a sharp image becomes fuzzy. You can have rosettes–the design made of half-tone screens–colliding instead of interweaving. It is most frequently manifested as ugly white gaps (also known as light leaks) between touching colors or a halo effect where a color is spread outside of its intended range.

Nevertheless, the consequences are much more than aesthetic. The package is the first point of contact of the product with the consumer in the packaging industry. A low-resolution logo or an off-center text is an indication of a poor product within, which is a blow to brand equity. Misalignment is a major cause of waste as far as manufacturing is concerned. Any meter of film that comes out of register cannot be sold. In cases where a press operator must halt a run to re-mount a plate or to troubleshoot a wandering web, the lost opportunity cost can easily be higher than the wasted material.

Diagnosing the Type of Misregistration in Printing

Misregistration is a problem that needs a forensic solution. An operator needs to determine the directional nature of the error before they can reach out to a wrench or turn a setting. They often rely on crop marks and the registration mark to verify the relative position of each layer. The action of the error on the substrate narrates the story of how it came to be.

Lateral (Transverse) Misregistration

This is when the print moves laterally, orthogonal to the web movement. When cyan is independent of yellow in a left-to-right direction, the problem is lateral. This normally indicates mechanical slackness in the cylinder bearing housing, a plate cylinder that is walking because it is not locked properly, or a web guide system that is hunting instead of maintaining a constant position.

Longitudinal (Machine Direction) Misregistration

In this case, the colors move either forward or backward in relation to the direction of the web travel. This is the most widespread and usually the most complicated type of error. It is nearly all about speed and tension. When the error varies with the increase or decrease in the speed of the press, then it means that the tension control system is not able to respond to the varying dynamics of the drive train.

Local or “Fit” Issues

When the registration is good in the middle of the web and becomes bad at the edges, or is good at the leading end of the impression and bad at the trailing end, it is a fit problem. This is not often a machine problem, but often a deformation of the printing plate itself, incorrect mounting methods, or a substrate that has physically deformed (fan-out) because of the absorption of moisture or heat.

The 3 Key Factors Causing Misregistration in Printing

Although the symptoms are apparent on the print, the disease is normally deep-rooted in the process. Maintaining exact color registration is a fine balance between the machine, the material and the operator. Any failure of any of these three pillars will lead to the collapse of the system.

Mechanical Instability and Wear

A printing press is a huge mechanism of moving parts, but it should work as delicately as a watch. With the aging of equipment, the physical tolerances that previously guaranteed accuracy start to loosen. Backlash is the main offender in older, gear-driven presses. This is the clearance or play between the teeth of the driving gear and the cylinder gear. With time, the teeth become worn out and leave a gap that enables the cylinder to stall or vibrate temporarily as it rotates.

Moreover, the overall vibration of the machine is a continuous destabilizer. Without the machine frame being rigid enough, the harmonic vibrations caused by high-speed rotation will be passed on to the print deck. This causes a rhythmic band of misregistration through the print, known as gear marking or barring. Even the state of bearings is vital; a worn bearing permits the cylinder shaft to rotate around a slightly different axis instead of rotating on an ideal axis, and it is physically impossible to obtain consistent registration, no matter how well the operator can do it.

Web Tension and Substrate Problems

In the case of converters of flexible packaging, the substrate is not a constant, but a variable. Such materials as Polyethylene (PE), BOPP, and PET are elastic. They stretch under tension, and deform under heat.

The nervous system of the press is the web tension control system. It has to have a specific, calculated amount of pull on the material between the unwind and the rewind. When the tension is excessive, the film is stretched between print stations. In the case where the ink is deposited on a stretched film, and the film is allowed to relax following the process, the print will shrink, causing a shorter print repeat and misregistration.

On the contrary, tension that is too low permits the web to weave and flutter. The thermal dynamics are also involved. In rotogravure and flexo, inter-station dryers are used to blast the substrate with heat to dry the ink. When this heat is not controlled, the thin film will be soft and will stretch and the next colors will be deposited in the incorrect position. This is especially troublesome to the effect of fan-out, in which the web expands at the end of the press.

Pre-press and Operational Errors

In many cases, the machine is the scapegoat for a preparation mistake. The flexographic plate is mounted at a critical point. When a plate is mounted with a slight skew, even a fraction of a degree, the error will increase with each rotation.

The setting of operational pressure is also crucial. Excessive pressure between the plate and the substrate leads to the deformation and spreading of the rubber plate, which is known as over-impression. This distorts the image size and it is impossible to register with the next colors which may be adjusted to the right pressure. Moreover, mounting tape (stickyback) is a matter of choice. Plate bouncing may occur when using a tape that is either too soft to support a heavy solid print, or too hard to support a fine screen.

Practical Troubleshooting: A Step-by-Step Checklist

Time is of the essence when a press run is compromised. Operators require a methodical way of isolating the variable. The checklist below will provide the physical checks that should be done immediately when registration drifts.

| Symptom | Probable Cause | Immediate Action |

| Lateral shifting (Side-to-Side) | Loose plate cylinder or sleeve. | Check the locking mechanism on the print station; ensure the mandrel is fully expanded/locked. |

| Edge guide sensor malfunction. | Clean the sensor eye; calibrate the edge guide system; ensure the web is centered. | |

| Plate lifting. | Inspect plate mounting; check for air bubbles or grease under the tape; re-mount if necessary. | |

| Longitudinal shifting (Machine Direction) | Tension fluctuation. | Check tension readouts; verify dancer roll movement is smooth; inspect brake/clutch consistency. |

| Slippage in the nip. | Increase nip pressure slightly on draw rollers; clean rollers to remove paper dust or ink buildup. | |

| Dryer temperature too high. | Reduce temperature in inter-station dryers to prevent film stretching/deformation. | |

| Rhythmic/Cyclical Misregistration | Gear backlash or damage. | Inspect drive gears for wear or debris; adjust gear mesh if applicable; listen for “chattering” sounds. |

| Out-of-round cylinder. | Check the Total Indicated Runout (TIR) of the plate cylinder and anilox roll. | |

| Local Misregistration (one area only) | Distorted plate mounting. | Remove the cylinder; strip and remount the plate with fresh tape, ensuring zero skew. |

| Trapped air under plate. | Pierce air bubbles with a fine needle and smooth the plate down firmly. | |

| Registration drifts with speed change | Tension control loop tuning. | The tension system is not reacting fast enough. Adjust PID settings (Gain/Integral) on the controller. |

Pre-press Strategies to Minimize Registration Errors

The prevention starts even before the job reaches the press room. A competent pre-press department is able to design out any possible registration problems by clever design and file preparation.

Trapping (Choke and Spread): Trapping is the process of deliberately overlapping neighboring colors to allow small mechanical misregistration to be corrected.

Spread: To enlarge a lighter object (such as a yellow letter) to make it slightly overlap a darker background.

Choke: To make a hole in a dark background, so that the light object within it extends over the edges. You can make a little overlap (usually fractions of millimeters) so that in case the press moves, there will be no white space.

Typography and Line Weight: Do not use multi-color builds on small text or fine lines. As an illustration, a recipe that involves the production of fine text with 100% Cyan + 100% Magenta + 100% Yellow (Registration Black) is a disaster. Even a minor movement will render the text illegible. Rather, apply one color (100% Black) or spot color to fine details.

Keep it Away from the Edge Designers: should not put important registration items close to the very edge of the plate gap or the edge of the web, where mechanical instability is most severe.

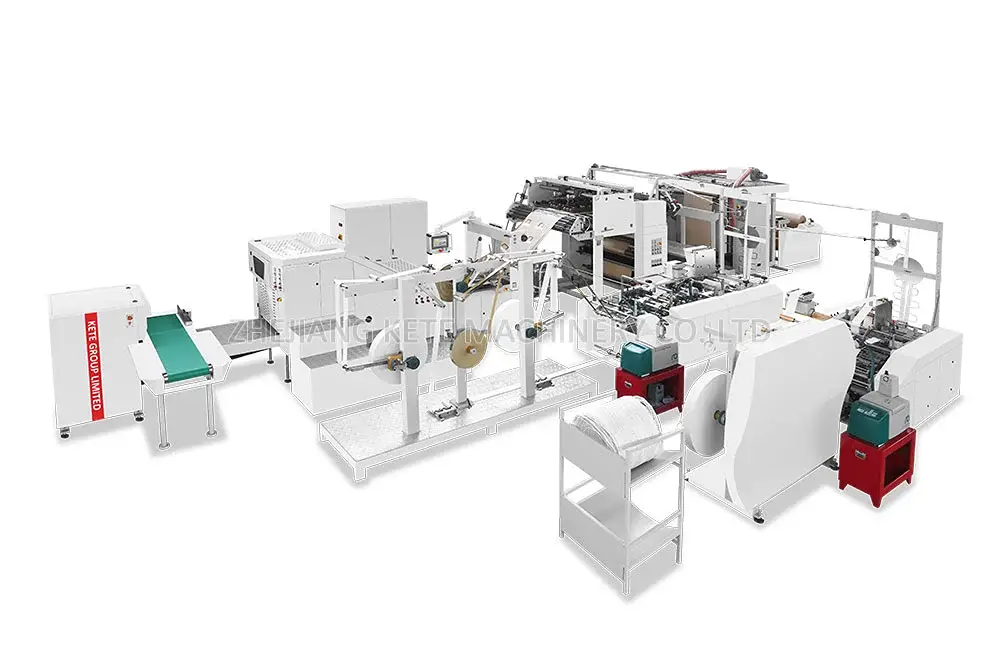

How KETE Helps to Print in Register in Printing

There comes a point in every production environment where troubleshooting hits a wall. When operators are skilled and plates are perfect, yet registration remains elusive, the limitation is invariably the machine itself. KETE addresses this not through mere adjustment, but through fundamental structural engineering. Our heavy-duty cast-iron frames and top-tier international core components provide the absolute stability needed to eliminate vibration, ensuring consistent ink performance even at high speeds.

This structural rigidity allows our servo-driven gearless technology to maintain precise registration across 2 to 8 color stations. Whether you are processing standard paper or challenging, heat-sensitive substrates like aluminum foil, PP woven fabrics, and FFS films, KETE’s closed-loop tension systems ensure perfect alignment. We further future-proof your production with ISO9001, CE, and RoHS certifications, fully supporting eco-friendly, food-grade water-based inks.

Beyond the hardware, KETE operates as your technical partner. Whether you require high-volume rotogravure solutions or agile flexo machines, our expert team helps match the specific machine configuration to your operational goals. We provide the industry insights and personalized support needed to ensure your investment translates directly into higher print quality and lower costs.

Best Practices for Maintaining Registration Consistency

The first step is to purchase high precision equipment; the second step is to maintain it. Routine gives birth to consistency. Facilities should transition to proactive stewardship as opposed to reactive repairs to achieve long-term stability in registration.

To begin with, plate mounting Standard Operating Procedures (SOPs) should be strict. Video plate mounting machines should be used as a matter of course eliminating the human eye factor. There should be a standard of tape thickness and hardness depending on the type of print job (solids or screens) and followed without exception.

Second, a Preventive Maintenance Schedule that is specifically oriented to the drive train is necessary. In the case of gear-driven presses, it implies periodic lubrication and checking of gear teeth. In any press, the state of the nip rollers (hardness of rubber and surface integrity) should be checked. A hardened nip roller that is not even will drag the web out of place.

Lastly, environmental control cannot be neglected. Paper and film are thermal-reactive and hygroscopic. A pressroom that has varying humidity and temperature will have varying registration during the day as the materials physically vary in size. Having a climate-controlled environment is a stabilizer to the whole production process.

บทสรุป

Misregistration in printing is not a secret; it is a physics calculation that has been unbalanced. It is the outcome of mechanical wear, material instability, or procedure variation. Although these problems can be addressed by experienced operators who can continuously adjust to them, this firefighting is at the cost of efficiency and production rate.

Finally, the misregistration solution is a holistic one. It needs pre-press designers who are aware of the tolerances of the process, operators who adhere to strict setup procedures, and, most importantly, equipment that is capable of meeting the demands of modern production. In a time when margins are narrow and quality requirements are precise, the use of old-fashioned mechanical integrity is liability. Investing in rigid, servo-driven technology and automated control systems, converters not only correct the issue of misregistration, but also remove the variables that lead to it.