Introduzione

There are a few processes in the great ecosystem of modern manufacturing processes as fundamental and as invisible as paper slitting. It is the defining, critical role that converts a huge, raw-format parent roll into the exact, usable products that drive our supply chains. This is not simply “cutting.” The material is terminated by cutting or sheeting.

Precision slitting is an active, ongoing process, an engineering field in which a failure is counted in microns and success is measured in product quality and production efficiency. It is the heart of the printing industry, packaging industry, and converting business, and its correct implementation plays a vital role in the final product.

What Is Paper Slitting

Fundamentally, slitting paper is the industrial process of slicing a large, wide roll of material (called a jumbo roll or master roll) into several smaller ones. The machine which does this is known as a “slitter rewinder,” as it does not merely cut, but must also rewind the strands thus cut into finished rolls of the correct density and alignment.

This must be differentiated with two other processes:

Sheeting: It is a cross-web process that cuts the material along its width to produce single flat sheets (as in office copy paper).

Trimming: This is an aspect of the slitting process in which the outer edges of the master roll are cut off, but is not the main purpose.

Slitting is a longitudinal or down-web process. The material is sliced as it passes through the machine and it is in the form of a continuous roll. It is the basic operation of the converting industry–reducing large, mill-sized rolls into forms which can actually be utilized by printing presses, packaging lines, and label applicators.

The Core Paper Slitting Process: A 3-Step Breakdown

Although the machinery may be very complicated, the basic physics of slitting and rewinding can be simplified into three steps, which are necessary and essential. The failure of any of these steps will undermine the whole operation.

Unwinding the Master Roll: Controlling Tension

It all starts at the unwind stand where the master roll, weighing several tons, is mounted. This is not a passive holder but an active heavy-duty braking system. All it does is control tension. When the roll is being pulled off the web, the unwind stand exerts a constant amount of resistance.

When the tension is excessive, the paper may stretch, deform or even break. When the tension is insufficient, the web will either be slack, flutter, or wander, and a straight, clean cut will not be possible. This first unwind tension is the key to the whole process; all the later quality is based on its stability.

The Slitting Stage: The Cut Itself

After being unwound and maintained at the ideal tension, the flat “web” of paper is sent to the slitting station. This is the core of the machine. In this case, the web is cut through a row of knives that are set to a specific precision that separates the material.

Even the cut itself should be surgically accurate. This step is nearly always assisted by a web guiding system (with optical or ultrasonic sensors) that identifies the edge of the paper and performs micro-adjustments to the alignment of the web as it passes through the knives. This guarantees that although the master roll may have been wound with imperfection, the end slit widths will be precise to a fraction of a millimeter.

Rewinding the Finished Rolls: Web Handling and Density

As soon as the cut is made, the web, now in the form of a series of thinner ribbons, passes into the rewind section. In this case, the ribbons are reeled onto new cardboard cores to produce the completed rolls.

This is arguably the most complicated step. The machine now has to construct several, distinct rolls, usually on the same shaft, and with new, independent tension settings. The ultimate roll density is determined by this rewind tension. When overdone, the rolls will be mushy and unstable. When overtightened, they may entrap air, distort the core, or form crowned rolls. This is the last phase and a fine balance of tension, pressure, and speed to produce completed rolls that are thick, stable, and usable.

Slitting Methods Explained: Choosing the Right Cut for Your Material

The cut itself is not a universal operation. The decision on the method of cutting is determined by the characteristics of the material (thickness, abrasiveness, and fragility). This is among the most important choices that any engineer or purchasing manager can make because the incorrect approach will result in low quality of edges, high levels of dust and quick wear of the machine.

Taglio a rasoio

This is the oldest and simplest way. It cuts through the paper with a single sharp razor blade- similar to a utility knife blade. The blade may be held in the open air (razor in air) or run through a grooved roll, which holds the web at the end of the cut.

Ideale per: Thin, non-abrasive materials such as plastic films, light foils and certain coated papers.

Pro: It is an extremely cheap and easy installation. It cuts very fine and leaves very little dust, on the right material, and it is very clean.

Contro: The blades are very easily worn out, particularly on any material containing abrasives (such as uncoated paper). It cannot be used with thick, rigid, or multi-layered materials.

Shear Slitting (Male/Female Knife)

It is the most versatile and the best quality of paper. It works just like a pair of high-precision scissors. The web is caught between two rotating circular blades, one male, the top knife, and one female, the bottom knife. The contact and stress of these two knives form a cutting motion that shears the material.

Ideale per: The broadest variety of materials, including delicate tissue and non-wovens, paperboard and laminates.

Pro: This technique yields a clean, flawless edge with little dust. The blades are strong, long-lasting and can be reshaped. This is the default choice for high-quality and high-speed applications.

Contro: More expensive to start with and needs a skilled and accurate set-up to position the top and bottom knives in the right place.

Crush Cut (Score Slitting)

It is a more brute force approach, which uses pressure to separate the material. The web is pressed against a hardened, usually dull-edged wheel and is held by a hardened roll known as an anvil. The huge pressure breaks or cracks the material, and it becomes split.

Ideale per: Rigid, thick or multi-layered materials such as composites, laminates and abrasive paper.

Pro: Extremely quick to install, tooling is very robust, and it can cut materials that would ruin other blades.

Contro: This technique inherently leaves a jagged, broken edge and produces a lot of dust. It cannot be used in applications that need a clean edge.

Key Industries and Applications That Rely on Paper Slitting

Since paper mills make material at huge, efficient jumbo widths, almost all other industries use this process to obtain material in a usable form. At the centre of: you will find paper slitting.

Packaging and Converting: The production of rolls of paper, board and laminates of a certain width to be used in packaging food, flexible pouches and box making.

Thermal Paper (POS/ATM): The whole business of receipts, ATM slips and event tickets is based on cutting jumbo thermal rolls into the small rolls we use every day.

Etichetta Stock: Slitting pressure-sensitive label stock and facestock to printers and automatic label applicators.

Stampa: Preparation of large coated and uncoated paper rolls to fit into particular web-fed printing presses.

Hygiene and Medical: Cutting non-woven diaper, sanitary, and medical-grade wipe fabrics.

Industrial and Specialty: Processing filter media and tea bag paper, as well as abrasives and battery parts.

Understanding Paper Slitting Machinery (Slitter Rewinders)

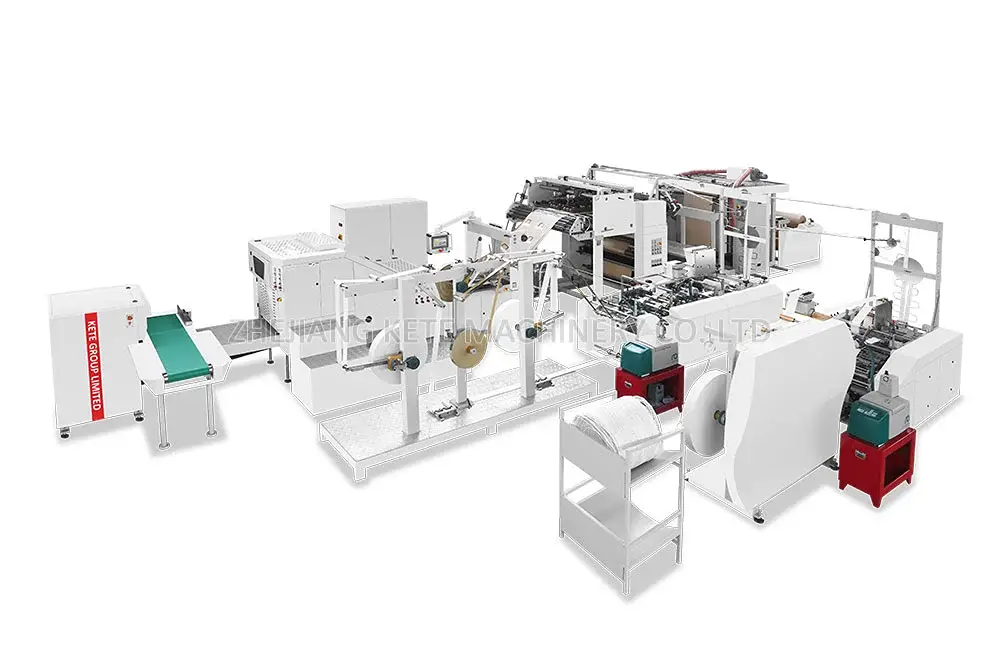

The entire system that incorporates the 3-step process is known as a slitter rewinder. Although the configuration can be different depending on the application, all industrial machines have the same basic components that you need to know before you can judge a solution.

| Componente | Descrizione | Funzione |

| Unwind Stand | Heavy-duty pneumatic or electronic brake, web guide | Controls tension and feeds the master roll |

| Sistema di guida web | Optical/ultrasonic sensors | Ensures alignment for precise slitting |

| Slitting Station | Razor, shear, or crush cutting assembly | Cuts the web to the desired width |

| Riavvolgimento Sezione | Center or surface winding shafts | Rewinds slitted rolls with controlled tension |

| Control System (PLC) | Central unit for controlling machine settings | Adjusts unwind/re-wind tension, speed, and knife positions |

The capabilities and performance of these machines are simply astounding. The limits determine the specification of a machine. Web width may be as small as dealing with narrow tapes, or as wide as master rolls a few meters. Materials Basis weight may be as fine as tissue (<20 gsm) or as strong as packaging board (>200 gsm). Speed is commonly calculated in hundreds of meters per minute. At these speeds and loads, Tolerance is the most important specification, the capability of the machine to maintain its width and location. A machine constructed using stiff frames, fine guides and high quality tooling can have a tolerance of ±0.1 mm.

Common Paper Slitting Defects and How to Prevent Them

A machine that has high specifications on paper may end up giving expensive scrap unless it is designed to address real-life issues. In practice, nearly all slitting failures are due to a few, common, avoidable defects. Their knowledge is essential to select a real solution.

Telescoping: This is where the layers of a completed roll slide past each other, as a collapsing telescope. It is a traditional tension management breakdown. It is due to uneven tension in the rewind, improper density control or absence of correct lay-on rollers to squeeze out air. It is an unstable roll that cannot be used and the customer will reject it.

Dusting: This is the production of fine paper dust at the cut point. It is the greatest adversary of the printing and food packaging business. This dust not only pollutes printing plates and machinery, but may also nullify food-safe certifications. It is usually due to improper cutting technique (crush cutting), dull blades or improper blade alignment.

Poor Edge Quality: Hairy, jagged, or burred edges. This is directly caused by dull blades, misaligned shear knives or razor blades on an abrasive material. A bad edge may get caught on downstream equipment, result in a web break, and is an obvious indication of a low-quality product.

Irregular Slit Width: The completed rolls are of different widths. This is nearly always a failure of the web guiding system or over-wander of the web by unstable tension. This results in huge wastage because out-of-spec rolls cannot be utilized.

KETE’s Advanced Slitting Solution: Where Precision Meets Efficiency and Quality

The defects described above are not inevitable. With over 15 years of experience, KETE’s R&D team engineers solutions for these exact challenges. This philosophy is embodied in our ‘Smart Slitting’ solutions, which are built to deliver an uncompromised balance of Precision, Efficiency, and Quality.

Precisione: We elevate precision standards. Our servo-controlled slitters maintain a ±0.1mm accuracy for clean edges and less waste, even at high speeds. This allows you to confidently slit delicate materials as narrow as 5mm, expanding your production capabilities.

Efficienza: We maximize your throughput. Our high-speed slitters run up to 500m/min, letting you manage large orders with ease. By handling jumbo rolls up to 2600mm wide, we reduce material changes and maximize production uptime. Our systems are also novice-friendly, with intuitive touch screens and labor-saving automation.

Qualità: We deliver a perfect, stable final roll. Our machines feature dynamic tension adjustment and anti-static processing to ensure flawless rewinding. “Engineered for Endurance,” every machine is built with durable components under the strict inspection of experienced technicians, ensuring reliable performance and low maintenance.

Conclusione

Paper slitting is much more than cutting paper. It is a fast, dynamic and extremely accurate process which forms the basis of modern production and trade. It is a balance of physics, of tension, speed, and blade geometry, which is constant. The first step to mastering the unwind-slit-rewind process is to understand the basics of the process, the variations between razor, shear, and crush, and the defects that are likely to occur during the process.

You are a converter and need to streamline a high-volume process, you are a printer and need a dust-free edge, or you are a manufacturer and you are entering a new market, it all depends on how good your process is. The second step is to select a partner that has not only mastered these fundamentals but has developed them into a stable, profitable solution.