소개

Color is not a frivolous element of industrial packaging; it is a vital element of brand equity and a key determinant of consumer behavior in the strict world of industrial packaging. In the case of the packaging printer, the capability of producing accurate, repeatable color on millions of impressions is the standard of professional competence. Although process printing (CMYK) is the basis of photographic reproduction, it is not always up to the high standards of corporate identity and special visual effects.

This manual examines the technical nature of Spot Color, which offers an analytical framework of how it is used, its economic rationale, and the mechanical demands of its perfection in large-scale production settings.

What is Spot Color

In order to establish a technical baseline for what is spot color in printing, one has to refer to the chemistry and physics of ink application. Fundamentally, what is a spot color? It is a pre-mixed pigment that is designed to produce a desired hue before it ever gets to the printing press unlike process color, which uses the optical mixing of four standard inks. A spot color in the context of the Pantone Matching System (PMS) or other proprietary color libraries, including Pantone colors, is a single, standardized ink formulation.

Technically, spot color is an independent variable in printing. It is not based on the interplay of several halftone screens to produce a visual outcome. Rather, it is used as a homogeneous layer of ink, which is solid. This autonomy guarantees that the color is the same no matter the mechanical variations that may arise during a run of a four-color process. To the manufacturer, spot color is the answer to the natural unpredictability of chromatic layering, which provides a stable and predictable output that is necessary in high-volume industrial production.

Spot Color vs. CMYK: Understanding the Critical Differences

The difference between spot colour and CMYK (Cyan, Magenta, Yellow, and Key/Black) can be best explained in terms of predictability and technical performance. Although CMYK is very effective in the reproduction of complex images and a broad range of colours using only four ink stations, it also adds variables that may undermine the integrity of the visual identity of a brand.

Predictability and Brand Integrity

The main benefit of spot color is that it is absolutely predictable. A particular shade of Brand Red is created in a CMYK environment by printing different percentages of Magenta and Yellow. When the density of the ink of the Yellow station is varied by even 3 per cent in a high-speed run, the red will be changed to an orange or pink. Such a difference is not acceptable to global brands that need their visual heartbeat to be the same in various continents and substrates.

Spot color removes this danger. Since the ink is already mixed to a desired L*a*b value, the printer has the task of ensuring a constant film thickness of ink. This makes the quality control process much easier and the brand integrity is maintained between the first impression and the millionth.

Technical Execution: Solid Ink Layer vs. Halftone Dots

The difference is even greater at the microscopic level. CMYK produces the illusion of color by the use of different sizes of halftone dots. A CMYK-printed surface can be viewed under a magnifying glass to reveal a pattern of rosettes. Although this is effective with the human eye at a distance, it leaves jagged edges on fine typography and thin lines.

Spot color, on the other hand, is a solid in architecture. It is used as a continuous, opaque ink layer. This gives it extremely sharp text and vector graphic edges. Spot color is functionally better in the packaging industry, where barcodes, legal disclaimers, and complex logos are required. Moreover, spot colors have a greater ink density, i.e. the color is more vivid and saturated than any simulation made by the four-color process.

When to Choose Spot Colors for Your Packaging Projects

The pressroom strategic decision-making process needs to know when the complexity of a spot color warrants the extra setup, particularly in print design and colour printing. Four main situations exist in which spot color is the best option:

Brand 일관성 Across Substrates: When you are printing the primary identity of a brand on a brown corrugated box and a high-gloss plastic film, it is virtually impossible to match the two using CMYK because of the varying absorption rates of the two materials. Spot color may be developed using various carriers and opacifiers to make the color the same no matter what surface it is used on.

Colors Beyond the CMYK Gamut: The CMYK color space is mathematically constrained. Bright oranges, dark purples, and bright greens tend to be out of gamut. When a design needs a degree of saturation that cannot be achieved with the CMYK mix, the only physical solution is special spot ink.

Big Solid Color: CMYK printing a solid background on a 1.2-meter web is a disaster. Any minor mechanical vibration or ink variation will result in visible banding or ghosting. A spot color offers a smooth, dense laydown that covers small mechanical anomalies.

기능적 정밀도: As noted, in the case of barcodes, QR codes, and micro-text, the sharpness of a non-halftone spot color is critical to technical compliance.

Beyond the Spectrum: Metallic, Fluorescent, and Functional Inks

The possibility to work with specialized inks is one of the strongest arguments in favor of traditional flexographic and rotogravure printing in the era of digital transformation. Although digital printing has achieved progress in small-scale production, it is still essentially constrained by its ink delivery systems.

Digital printers make use of the so-called thin-film technology, in which low-viscosity inks are required to flow through microscopic nozzles. This eliminates the use of huge pigment particles. By comparison, flexographic and rotogravure presses are a type of sculptural ink application. Since these machines involve physical contact, through an anilox roller or an engraved cylinder, they are capable of transferring high-viscosity fluids with large particulate matter.

Metallic Inks: These are made of real pieces of aluminum or bronze. These flakes should be large enough to reflect light in order to produce a real metallic luster. Digital nozzles would be clogged immediately, whereas a rotogravure press can deposit a thick reflective layer to form a mirror-like finish.

Fluorescent Inks: These need a large amount of ink to give them their neon effect. The traditional presses are capable of providing the required pigment load, which cannot be achieved by digital toners.

Functional Inks: This group consists of thermochromic inks (temperature-sensitive), conductive inks (smart packaging), and scratch-off finishes. The chemical properties of these fluids are frequently incompatible with digital inkjet heads.

Cost vs. Quality: The Economic Logic of Spot Color Printing

Another myth that persists is that spot colors are always more costly for your next print project. Although it is factual that a spot color needs a special plate, special ink combination, and an additional wash-up, the economic aspect is more complex when considered in terms of overall production cost.

Waste (substrate spoilage) and press downtime are the most important cost-drivers in long-run packaging. When a printer tries to match a critical brand color with CMYK, they can easily waste hours color hunting on the press, adjusting ink keys, changing pressures, and wasting thousands of meters of material to get the mix just right.

The match is transferred off-press to the laboratory by a spot color. The ink is checked prior to it reaching the fountain. After the press, the color is right after the initial few meters. This waste of make-ready is minimized and the guarantee of a high yield of marketable product frequently makes spot color the less expensive option in large-scale production. Moreover, when a job needs only two colors (e.g., Black and a Spot Red), it is much less expensive to run a two-color job than a four-color process job both in terms of plate costs and energy consumption.

Scaling Capability: Matching Machine Configurations to Color Complexity

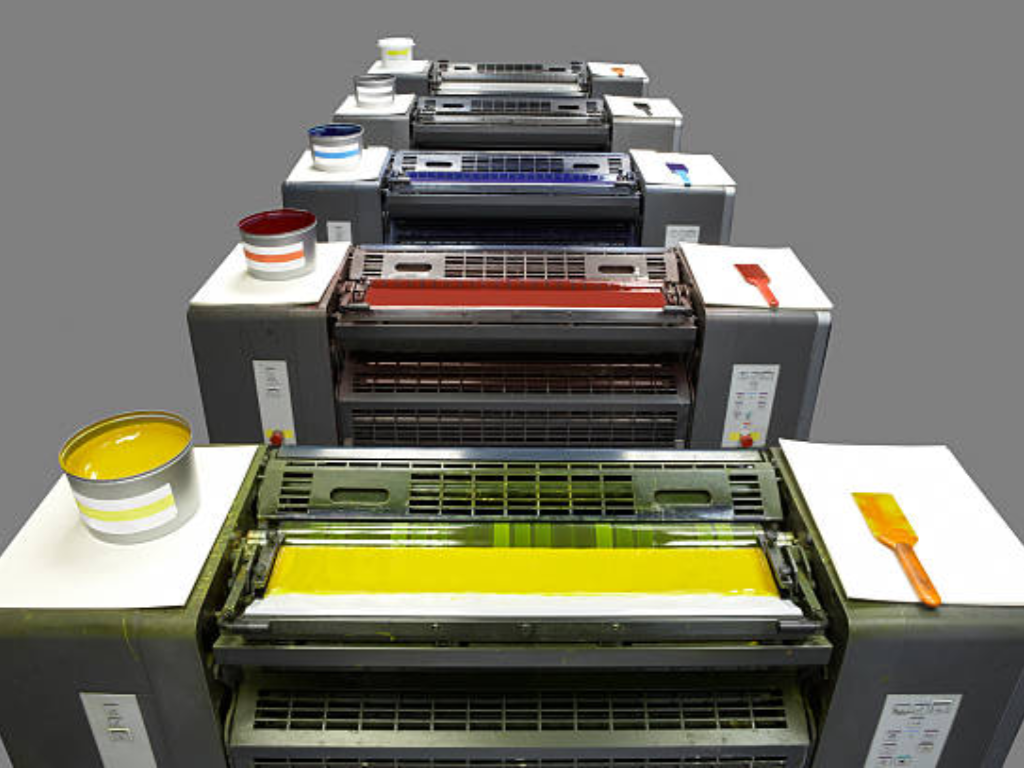

One of the most important decisions that any manufacturer can make is the number of color stations that they need to have in their facility. Machine configurations in the equipment market are not of more is better but of Single Pass Efficiency.

4-Color Configurations: These are the process printing entry-level. But, as we have determined, a 4-color machine does not allow a spot color when a photographic picture is being printed. This causes the printer to pass the substrate through the press again, a process that doubles the labor cost and the chances of misregistration.

6-Color Configurations: This is the current industry standard of standard packaging. It permits the complete CMYK process and two extra stations. This usually fits a “White Base” (needed to package the film) and one Brand Spot Color.

8 to 10-Color Configurations: These are the high-end segment of the market, which offers the strategic flexibility needed in the modern high-end packaging. With an 8-color press, a manufacturer can print a complex design with a white base, the CMYK process, two different brand spot colors, and an overprint varnish, all in one pass. This design takes care of all the visual and functional packaging needs in one process. To the modern printer, an upgrade to 8 or 10 color system by a manufacturer is a strategic step to win high-margin, complex contracts with global brands.

| Station Count | Typical Application | Spot Color Capacity | Strategic Value (ROI & Efficiency) |

| 4 Colors (Baseline) | Simple paper bags, monochrome labels, basic cartons. | Zero (if CMYK is utilized for imagery). | Cost-effective entry for low-complexity niche jobs. |

| 6 Colors (Standard) | Retail pouches, FMCG packaging, standard labels. | Medium (CMYK + White Base + 1 Spot Color). | Industry standard for versatile, mainstream production. |

| 8 Colors (Premium) | High-end food wrap, cosmetics, flexible electronics. | High (CMYK + White + 2 Spots + Overprint Varnish). | Maximum ROI via single-pass efficiency & waste reduction. |

| 10+ Colors (Elite) | Global brands, complex anti-counterfeit, luxury tobacco/alcohol. | Ultimate (CMYK + Double White + 3 Spots + Functional Coating). | Strategic moat for high-margin, complex global contracts. |

The Role of Advanced Machinery in Perfecting Spot Color Delivery

The theoretical benefits of spot color can only be realized if the printing press possesses the mechanical integrity to deliver it. A spot color is only as good as the consistency of its application.

Kete: Engineering Precision into Every Color Station

At Kete, we approach the printing machine as a precision instrument designed for the rigors of 24/7 industrial production. Perfecting spot color delivery requires three mechanical pillars:

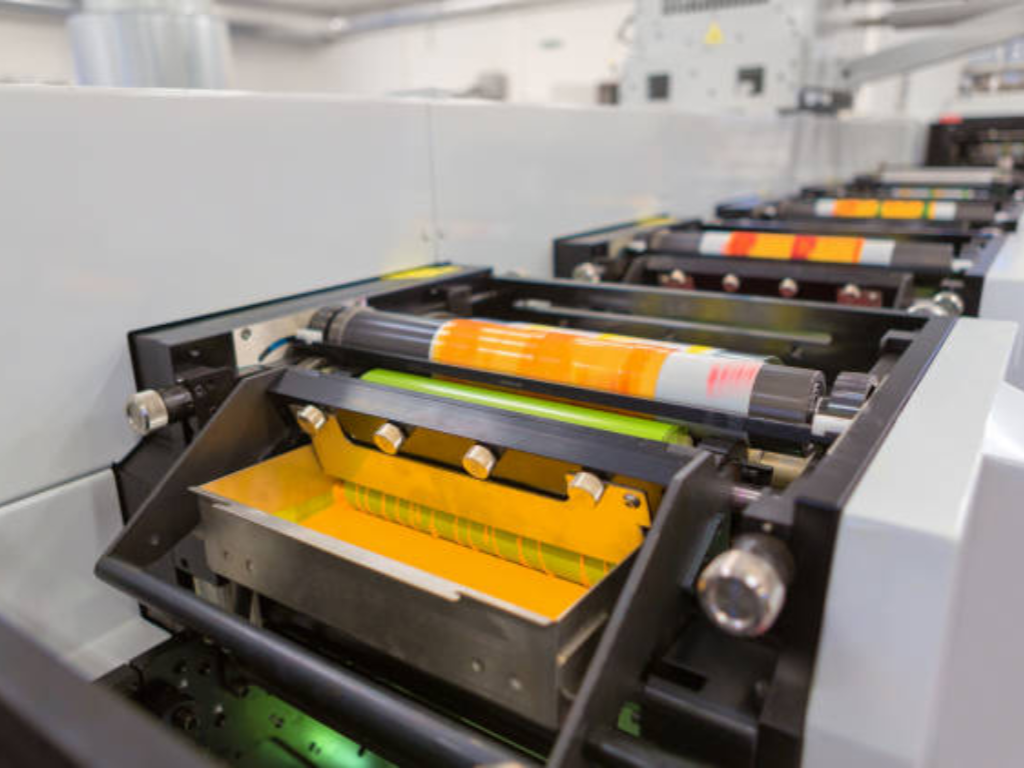

Ink Transfer Stability: In our printing machines, we utilize high-precision ceramic anilox rollers and doctor blade assemblies that ensure a constant volume of ink is transferred to the plate. This prevents the “color drifting” that occurs in inferior machines when ink temperature or press speed fluctuates.

Dynamic Tension Control: When printing multiple spot colors on thin, flexible films, the substrate tends to stretch. If the tension is not managed with millisecond-level accuracy, the spot colors will not “hit their marks” (registration). Our presses utilize advanced servo-motor technology to maintain a constant tension profile, ensuring that a spot color logo sits perfectly centered within its designated space.

소재의 다양성 및 기판 Integrity: Whether processing BOPP, PET, or heavy paper, our systems maintain structural stability throughout the print run. Kete’s engineering ensures that specialized applications do not compromise web tension or lead to thermal deformation during the drying stage.

By focusing on the engineering of the individual color station, Kete provides printers with the stability required to manage the most complex color profiles in the industry.

결론

The process of converting a digital graphic design to a physical package is a process that is full of technical variables. The packaging printer has the best tool to use, which is spot color, to remove these variables and guarantee absolute fidelity. With the knowledge of the chemistry of the ink, the physics of the transfer, and the economic rationality of the pressroom, printers can transform their service into a high-stakes brand stewardship, rather than merely manufacturing. We are also determined to supply Kete mechanical equipment, high-precision flexo and gravure systems, which give this degree of perfection. Ultimately, the real worth of a machine lies in its capability to provide the customer with the precise shade of color, each and every time, without fail.