The quality of products and efficiency of production are key to success in modern printing and packaging. Inert surfaces are naturally present on many common materials such as plastic films, paper, non-woven fabrics, and metal foils. This renders printing inks, coatings, and adhesives difficult to adhere. Inadequate adhesion influences product appearance and may result in more waste, which costs more. This is solved by corona surface treatment. It is an effective and efficient surface pre-treatment. It greatly enhances the surface energy of the material, which guarantees clear prints and robust bonds. This assists your printing and packaging machines to work optimally. KETE is a professional manufacturer of flexible printing and packaging machines, which also provides high-quality corona discharge equipment to make your production line perform well.

What Is Corona Treatment?

Corona surface treatment is a process of modifying the surface of the material through high frequency and high voltage electrical discharge. Its main aim is to increase the surface energy of the material. This increases its wettability and printing inks, coatings and adhesives bond more easily. The most common measurement of this enhanced surface energy is the dyne level. The quality and efficiency of the products of soft packaging processors (e.g., polypropylene, polyethylene, polyester film, paper, non-woven fabric, and metal foil), and packaging companies in the food, beverage, beauty, and personal care sectors are dependent on corona surface treatment. It removes problems like blurry prints and delamination caused by low surface energy, which streamlines your production lines and makes them more efficient. KETE is aware of the importance of corona surface treatment. Our corona discharge equipment is designed well and it fits perfectly with KETE printing, laminating, slitting and bag-making equipment, which allows printers to get better results.

How Corona Treatment Works

Corona treatment is a process that uses high voltage ionizing air plasma. This forms a corona discharge plasma region on the material surface. When the material moves through this zone, high energy electrons and ions strike the surface and cause changes:

- Physical Roughening: The surface gets slightly rough at a microscopic level, increasing physical bonding points.

- Chemical Modification: The chains of molecules on the surface of the material open. Functional groups that contain oxygen (such as carbonyl, carboxyl, and hydroxyl) are added. This greatly enhances surface activity and polarity.

- Surface Energy Boost: These new chemical groups increase the surface energy of the material. This alters it to be hydrophilic. The surface can then be wetted better by liquids such as inks, coatings or adhesives.

This is an accurate and controllable low temperature corona discharge plasma process. It provides homogeneous and repeatable treatment, which is essential in high precision, high speed industrial printing and bag-making machines. The treatment can be adjusted in a fine manner. KETE has sophisticated control systems in its corona discharge equipment. We guarantee accurate and stable treatment, which is a good assurance to your production.

Diverse Applications of Corona Treatment Across Industries

Corona surface treatment’s benefits make it essential in many industries, especially in soft packaging and printing. KETE, as a manufacturer of flexible printing and packaging machines, knows how important corona surface treatment is for these applications:

- Flexible Packaging: A widely used surface treatment method for plastic films (like polyethylene, polypropylene, polyester, and BOPP) before printing inks application, laminating, and coating. It ensures strong ink adhesion and high bond strength between layers, providing reliable packaging for food, beverages, beauty, and personal care. This is crucial in the extrusion process for film production.

- Label Printing: Increases the surface energy of the material for various self-adhesive label materials (paper, film) for clear, durable prints.

- Extrusion Coating and Lamination: When producing multi-layer composite materials, corona surface treatment significantly improves the bond between different material layers, ensuring stable product structure.

- Paper and Paperboard: Improves the ink absorption and water resistance of paper surfaces, enhancing print quality.

- Medical and Industrial Fields: Plays a key role in producing medical device packaging, dimensional objects, and automotive interior materials. These require high-adhesion coatings or bonds, including the treatment of injection molded parts.

The Pros and Cons: Is Corona Treatment Right for You?

When considering corona treatment, understanding its advantages and limitations is important.

Pros:

- Excellent Adhesion: This is the core benefit. It significantly improves the bond strength of printing inks, coatings, and adhesives on various substrates. This ensures high-quality finished products. The dyne level achieved is a direct measure of this improved adhesion.

- Wide Material Compatibility: It effectively treats many plastic films, paper, non-woven fabrics, and metal foils. This lets your printing and packaging equipment handle more orders. KETE’s equipment handles diverse raw materials well. With corona surface treatment, it maximizes material potential for optimal printing and lamination, enhancing the properties of a surface.

- Increased Production Efficiency and Cost Reduction: It reduces waste and downtime caused by poor adhesion, boosting overall production efficiency. High-quality products also mean fewer customer complaints and stronger market competitiveness.

- Economical and Eco-Friendly: Compared to some chemical treatments, corona surface treatment is more cost-effective. It involves no toxic chemicals, so it has less environmental impact. It operates at ambient temperature.

- In-Line Processing: It integrates easily into existing production lines for continuous, high-speed treatment. This perfectly matches KETE’s efficient and stable automated equipment, ensuring the effectiveness of corona treatment.

Cons:

- Temporary Effect: The treated effect might decrease over time (especially depending on storage). Treatment usually needs to happen right before processing.

- Material Limitations: Some materials with high slip agents or additives might show poor corona surface treatment results or need higher intensity of the treatment. Different amounts of slip in a material can lead to different characteristics in treatment outcomes.

- Ozone Production: A small amount of ozone is produced. Good ventilation is needed.

- Safety Concerns: It involves high voltage electricity. Strict safety rules must be followed during operation.

Corona vs. Other Surface Treatments: A Brief Comparison

In surface treatment, other common methods exist besides corona treatment. Knowing their differences helps you make a better choice.

| Treatment Method | Principle | लाभ | नुकसान | लागू परिदृश्य | Advantage Compared to Corona Treatment |

| कोरोना उपचार | High-voltage discharge ionizes air | Efficient, economical, wide material use, in-line processing | Effect is temporary, ozone production | Flexible packaging, printing, extrusion, lamination, high-volume production | Combines efficiency, economy, and broad applicability. |

| Flame Treatment | Burning flame heats and oxidizes surface | Low cost, fast processing | Less precise, can damage heat-sensitive materials, fire risk | Thick or heat-resistant materials, like car bumpers, storage tanks | Less precise than corona, not suitable for films. |

| Plasma Treatment | Plasma generated under vacuum or atmospheric pressure | More thorough, longer-lasting effect, no ozone | High equipment cost, typically slower processing, limited batch capacity | High-end medical devices, electronic components, precision coatings | Corona is more cost-effective and efficient for high-volume, high-speed production. |

| Chemical Primers | Applying chemicals to change surface properties | Long-lasting effect, very strong adhesion | High cost, environmental pollution, requires drying time, complex process | Specific high-performance coatings or bonding, small batch production | Corona is more eco-friendly, more efficient with in-line processing, no drying step. |

Corona surface treatment is typically the most suitable option to use in packaging and printers that require continuous and efficient production. It is cost-effective, fast, and integrative. It is a perfect match to the high-value printing and packaging equipment that KETE provides. The corona discharge equipment provided by KETE is aimed at fulfilling this industrial requirement, and it is seamlessly integrated and performs well in your production line. This shows the possibility of treatment for various materials.

Choosing the Right Corona Equipment

It is important to select the appropriate corona equipment that will suit your industrial printing and packaging machines. This not only affects the outcome of treatment but also production efficiency and the returns on investment. The following are some of the main considerations that should be made when making a choice:

- Material Width and Line Speed: Make sure the corona discharge equipment’s effective treatment width and speed match your production line, especially with KETE’s high-speed, high-volume equipment. Consider the sample of the actual film you will be running.

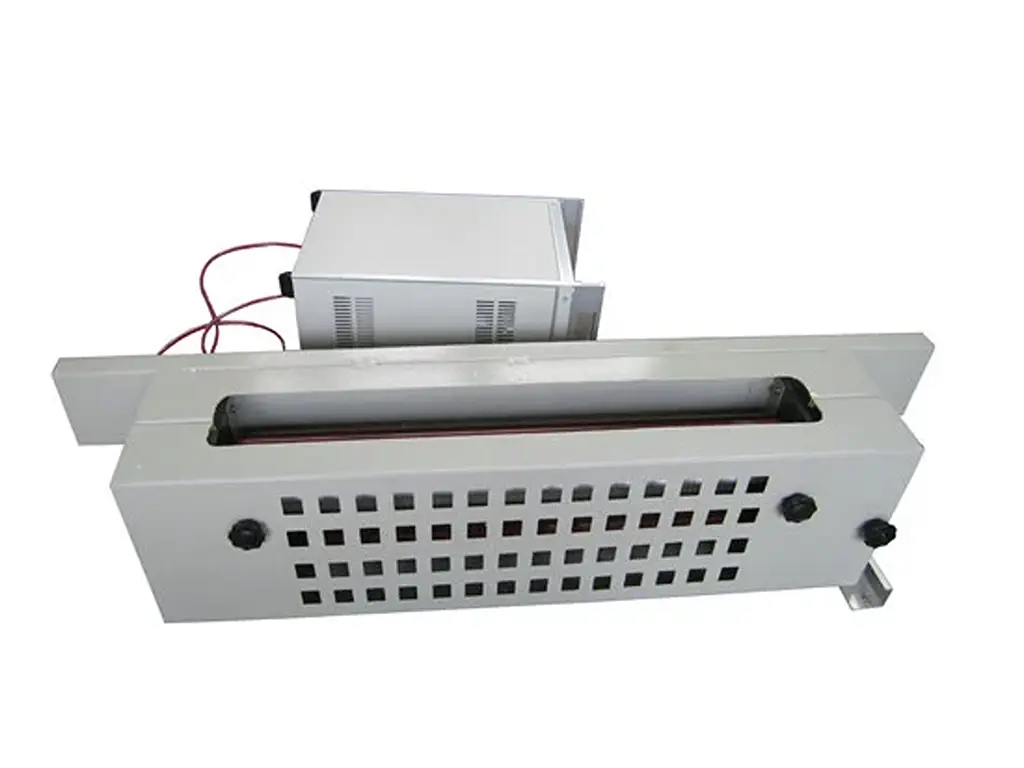

- Generator Power and Electrode Design: Generator power defines the intensity of the treatment. The design of electrodes influences uniformity of treatment. Select a generator that is powerful, has a stable output, and uses higher frequency power with an efficient cooling system. Also, select electrodes with a sharp tip design specific to different materials (such as ceramic, metal) in a linear array of electrodes. The electrical power of the corona discharge equipment manufactured by KETE utilizes components from world-known brands, including Delta, Schneider, and Panasonic. This guarantees consistent and dependable performance of equipment.

- Integration and Compatibility: Modern corona discharge equipment should integrate seamlessly into your existing production line. It should work well with printing machines, laminators, slitters, and other equipment. KETE’s corona discharge equipment is designed for this seamless integration. They work perfectly with our printing machines, bag-making machines, and slitters, forming an all-in-one solution.

- Reliability and Durability: Industrial production needs very stable equipment. Choose equipment from reputable manufacturers. It should meet ISO 9001 quality management standards and CE certification. This ensures long-term reliable operation. KETE’s equipment strictly follows these quality control standards. We have over thirty years of manufacturing experience, guaranteeing excellent quality for our equipment.

- Safety Features: Since कोरोना उपचार involves high voltage, the equipment should have complete safety measures. These include overload protection, short-circuit protection, and emergency stop features.

Tips & Best Practices in Using Corona Treatment Equipment

Correct operation and maintenance maximize the performance and lifespan of corona discharge equipment. This ensures your printing and packaging production line runs efficiently.

- Regular Cleaning and Inspection: Clean electrodes and counter rollers regularly. Clean off any dust, ink, or residue material from the surface of the material to avoid uneven discharge.

- Parameter Optimization: Fine tune corona surface treatment power and frequency. This should be done depending on the different characteristics of the material, thickness, line speed, and the required dyne level or material’s surface energy.

- Surface Energy Testing: Test the surface energy of the material regularly with dyne pens or contact angle meters. This guarantees that the effects of corona treatment are of standard. This is the direct measure of treatment success.

- Environmental Control: Maintain a clean and dry production environment. High humidity and dust should be avoided as they may influence the effects of corona treatment and the life of the equipment.

- Personnel Training: Provide professional training to the operators. They are expected to know how to operate equipment, safety measures, and general troubleshooting.

- Spare Parts Management: Have common wear parts such as ceramic electrode tubes and fuses on hand. This assists in minimizing downtime in case of replacement of parts.

- System Upgrades: The majority of modern machines have the capability of online system upgrade. This will make sure that equipment is always at its best, keeping up with technology.

KETE’s corona discharge equipment is highly compatible with materials. It is able to adapt to different amounts of slip and various material processing requirements, and you can easily optimize parameters for the best effectiveness of corona treatment. KETE offers professional installation and training of operations. This will make your team competent in the use of our corona discharge equipment. KETE also offers spare parts support on common wear parts so your equipment can run continuously. The corona discharge equipment of KETE also allows online system upgrades, ensuring your equipment is up to date.

निष्कर्ष

In contemporary printing and packaging, corona surface treatment is essential. It is one of the most important surface modification techniques to enhance the quality of products and efficiency in production. Knowledge of its functioning, its extensive uses, and selection and maintenance of corona discharge equipment assist you to make intelligent choices. This makes your production line competitive and improves the properties of a surface.

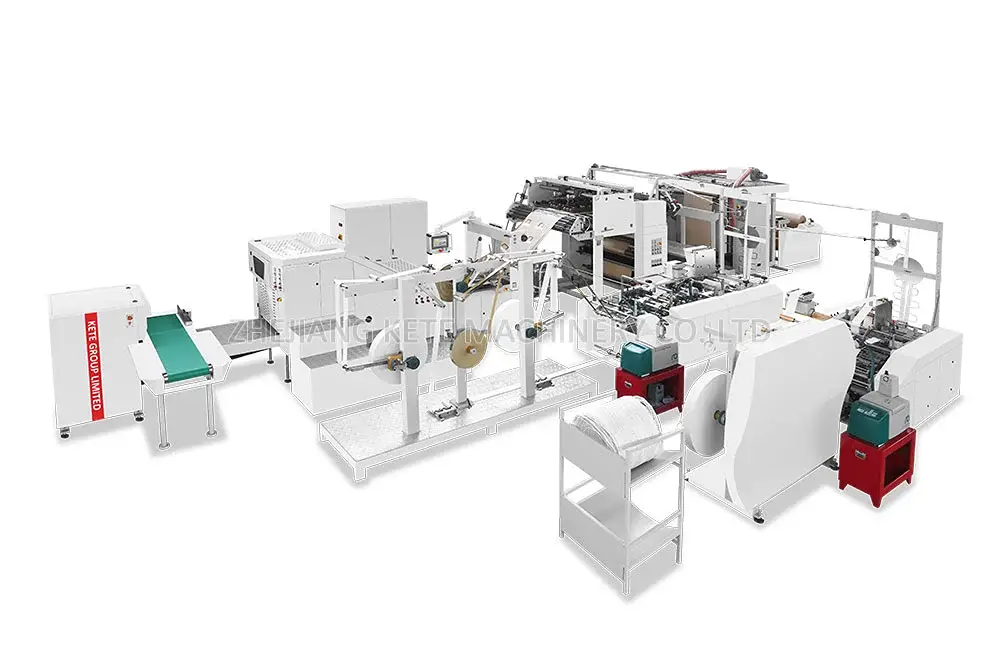

KETE boasts of more than thirty years of manufacturing experience. We sell more than 2,000 units of equipment per year and export to more than 80 countries. We do not only provide high-quality printing, laminating, slitting, and bag-making machines, but also high-performance corona discharge equipment. We understand that the combination of great equipment and effective pre-treatment is the key to customer success. KETE is a one-stop shop that provides printing, laminating, and slitting to bag-making. We also believe in customization, and you will have the right equipment configuration that suits your needs. By selecting KETE, one will collaborate with a quality-conscious, customer-focused, innovation-driven, sustainability-oriented, and honest company.

Now is the time to attain better dyne level and adhesion for your printed and packaged products using the corona discharge equipment by KETE. This will completely enhance your competitiveness in production! Get in touch with KETE today to find out more about our tailored solutions!