مقدمة

The handle is the most underrated element in the world of packaging. However, it is the main physical point of contact between a brand and a consumer. As a customer leaves a store carrying a paper bag with handles, that loop is the only thing that separates his or her purchase and the sidewalk. A failure in this case is not just a structural failure; it is a betrayal of trust.

To retailers, the decision of a paper bag handle is a trade-off between beauty and cost. To manufacturers, however, the equation is much more complicated. It entails tensile, adhesive chemistry, and production speed. The market is overwhelmed with choices, starting with simple die-cut holes and ending with complex twisted cords, each of which needs a unique manufacturing strategy.

This guide goes beyond the superficial descriptions to examine the mechanics, durability and cost structures of various paper bag handle types. Whether you are sourcing the packaging for a brand, manufacturing it as a dedicated supplier, or running the machinery that makes it, it is necessary to know these variables to ensure quality control and profitability.

Main Types of Paper Bag Handles

To a layman, handles for paper bags are just a way of picking up a bag. Each type is a particular set of material requirements and machine configurations for a manufacturer. The market can be divided into four dominant architectures, each of which serves a specific sector of the retail and food service industries.

Twisted Paper Handles

The retail industry is the workhorse of the twisted paper handle. It is the quintessential shopping bags handle for fashion boutiques, department stores, and general merchandise. It is made structurally of a single or double ply of kraft paper which has been mechanically twisted into a rigid cord. This cord is then attached with two layers of a paper patch (commonly referred to as a reinforcement patch) which is then stuck to the inside of the bag.

The genius of the twisted handle is its strength-to-weight ratio. The twisting process also straightens the fibers of the paper and the tensile strength is greatly enhanced as compared to a flat strip of the same weight. Manufacturing-wise, they are manufactured on high-speed automated lines. The equipment should have a steady tension; otherwise, when the twist is loose, the handle becomes cheap and weak. When it is tight, the fibers of the paper can shear. A twisted handle when properly applied to precision equipment, provides a strong, semi-rigid loop that remains upright, and can be easily picked up and loaded by cashiers.

Flat Paper Handles

When the twisted handle is the retailer, the flat handle is the monarch of large-volume food service and grocery markets. It appears visually as a folded piece of paper, usually of the same material as the bag. It is commonly attached to the bag with a larger surface area than the twisted cord, and in cheaper designs, the bag itself may not have a top fold.

The first benefit in this case is logistical efficiency. Since the handles are completely flat against the bag, these units can be packed in shipping cartons much more densely than their twisted counterparts. This lowers the unit logistics costs. It is also usually quicker and uses less adhesive to manufacture flat handles. The trade-off is, however, apparent in ergonomics. A flat handle will provide a sharper edge against the hand when lifting heavy items, and is not as appropriate for heavy items such as hardware or large electronics, but ideal for a lightweight takeaway meal.

Die-Cut Handles

The die-cut handle is the philosophy of less is more. No external attachment; the handle is merely a form, an oval or a kidney bean, punched out of the upper part of the bag itself. To avoid the bag tearing as soon as it is picked up, the space around the cut is often strengthened with a piece of cardstock glued under the surface or a fold of the bag fabric.

This type is common in small pharmacy bags, greeting card envelopes, and trade show handouts. The manufacturing process is simplified since no separate handle-making step is involved; it is an inline punching process. Nonetheless, this design has a serious drawback of reducing the volume of the bag. The usable capacity is less because the hand of the user takes the upper part of the internal space of the bag. It is a smooth solution, yet one that has rigid functional boundaries.

Rope & Ribbon Handles

Rope and ribbon handles are at the top of the pyramid. These belong to the sphere of luxury goods, jewelry, and luxury cosmetics. The materials are no longer pure paper but cotton, polypropylene (PP), polyester or satin.

These handles are not often glued structurally. Rather, the bag has punched holes (usually supported by metal eyelets), and the handle is threaded through and knotted by hand or by semi-automated tipping machines. Although they are more comfortable and have a high-quality tactile experience, they add a lot of complexity. It is less fast in production and the use of non-paper materials makes it difficult to recycle. They are a sign of luxury because they appear and feel costly, which, as a production matter, they are.

A Quick Comparison Guide of Paper Bag Handles

The choice of the appropriate handle is not a question of taste; it is a question of utility versus cost. The functional differences are further subdivided into the following matrix to help in matching the component to the application.

| نوع المقبض | Load Capacity | Comfort Level | سرعة الإنتاج | Cost Index | قابلية إعادة التدوير | أفضل تطبيق |

| Twisted Paper | 5 – 10 kg | واسطة | 150 – 250 pairs/min | $$ (1.2x) | ممتاز | Fashion, Retail, Clothing, Gifts |

| Flat Paper | 3 – 6 kg | قليل | 200 – 300+ pairs/min | $ (Base) | ممتاز | Grocery, Takeaway |

| Die-Cut | 2 – 4 kg | Low / Med | Inline (Fast) | $ (In-bag) | ممتاز | Pharmacy, Events |

| Rope (Cotton/PP) | 8 – 15+ kg | عالي | < 40 pairs/min | $$$$ (3x+) | Poor / Mixed | Luxury, Jewelry |

| Ribbon | 3 – 7 kg | عالي | Manual / Slow | $$$$$ (5x+) | Poor / Mixed | High-end Cosmetics, Boutique |

Analysis:

As the matrix shows, tactile luxury and manufacturing efficiency tend to have an inverse relationship. Comfort features like Rope or Ribbon handles are usually costly in terms of production speed and recyclability. In the case of mass-market industries such as food service and fashion retail, the functional equilibrium is the Twisted and Flat handles. They are sufficiently comfortable and have a high load capacity and can be automated to produce over 200 pairs per minute. This scalability renders them the strategic option in high-volume orders where unit cost and throughput are the metrics of choice.

What Defines a High-Quality Paper Bag Handle

Quality in manufacturing is not an abstract concept but can be measured. When we examine the failure of a paper bag handle, it is not often that the paper itself breaks. It is nearly always an engineering or application failure. Three manufacturing metrics determine a high-quality handle.

Tensile Uniformity

In the case of twisted handles, the quality depends on the uniformity of the torque used in the twisting process. A poor-quality handle will contain soft spots where the twist is loose. These spots become elongated under load, resulting in the fraying or detachment of the handle from the patch. High-quality handles are produced on a precision paper bag handle-making machine with real-time tension monitoring so that the paper rope is solid and consistent throughout.

The Adhesion Matrix

The most common point of failure is the intersection of the handle and the bag. This is a role of the patching process. A better handle has a reinforcement patch of an exact weight of GSM (grams per square meter) compared to the bag. Moreover, the glue should be precise. Excessively little glue, and the handle peels off (shear failure). Excess glue and it spills over the paper and spoils the appearance or bags get stuck together on the production line. The adhesive tack time should be equal to the machine speed.

Positioning دقة

Handles are placed in automated production at a rate of more than hundreds of bags per minute. Even a few millimeters of positioning can cause a shift in the center of gravity. When the handles are not symmetrical, the load is not distributed evenly and the bag will lean to one side and the stress on one handle will be more. Quality production involves the use of servo-driven systems to make sure that the position of the handles is the same on all individual units, irrespective of the speed of production.

The Hidden Cost Factors in Paper Bag Handle Production

In determining the cost of a paper bag, it is clear that the cost of the raw material of the paper is involved. But the actual price of the handle is concealed in the efficiency of production. It is here that the profit margin is made or lost.

Labor vs. Automation

Threading and knotting (tipping) of rope handles is usually a semi-automated or manual process. This is a huge per-unit cost, even with cheap labor and constrains daily output. On the contrary, inline handling and pasting a continuous processes. A twisted handle is slightly more expensive to make of material than a flat handle, but both are exponentially cheaper to install than a rope handle since they eliminate the human factor completely.

Machine Downtime and Waste

The handle that prevents the line is the most expensive. The handle application unit is usually the most complicated module in high-speed bag making. When the handle-making machine makes ropes of uneven thickness, they will block the pasting unit.

Think about the economics: A machine that is set to run at 300 bags per minute and jams 10 minutes is losing 3,000 units of production. Moreover, the waste of the startup (paper and glue to recalibrate the machine) accumulates. Thus, the accuracy of the handle making machine is the direct determinant of the profitability of the handle pasting process. Poor quality machinery can be cheaper on the sticker price but the cost of operation in terms of jams, waste and maintenance will drain profit margins in the long run.

KETE: Enhancing Quality and Efficiency with Advanced Machinery

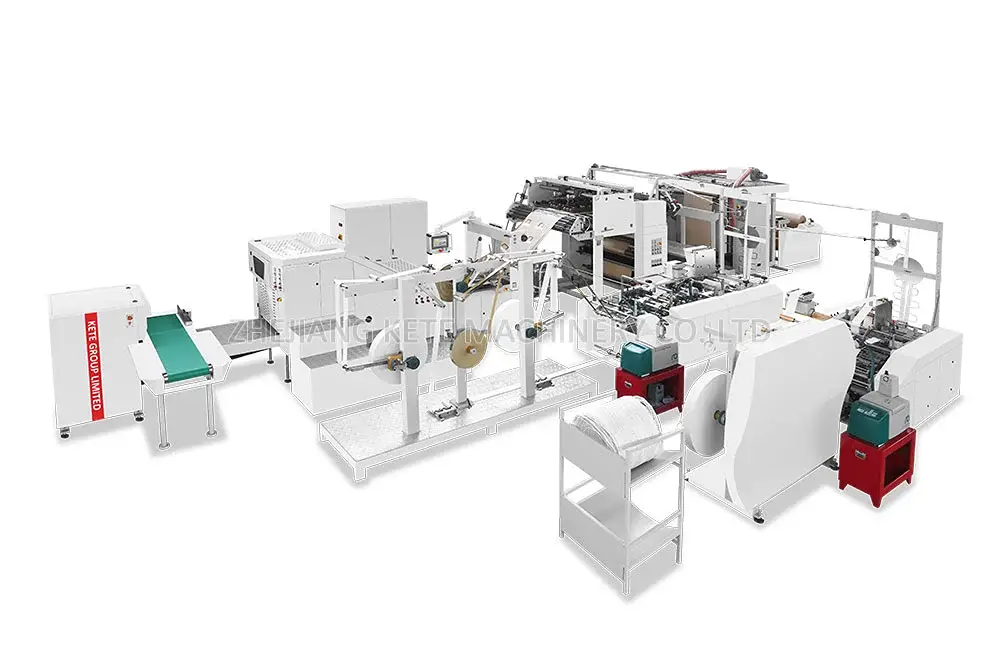

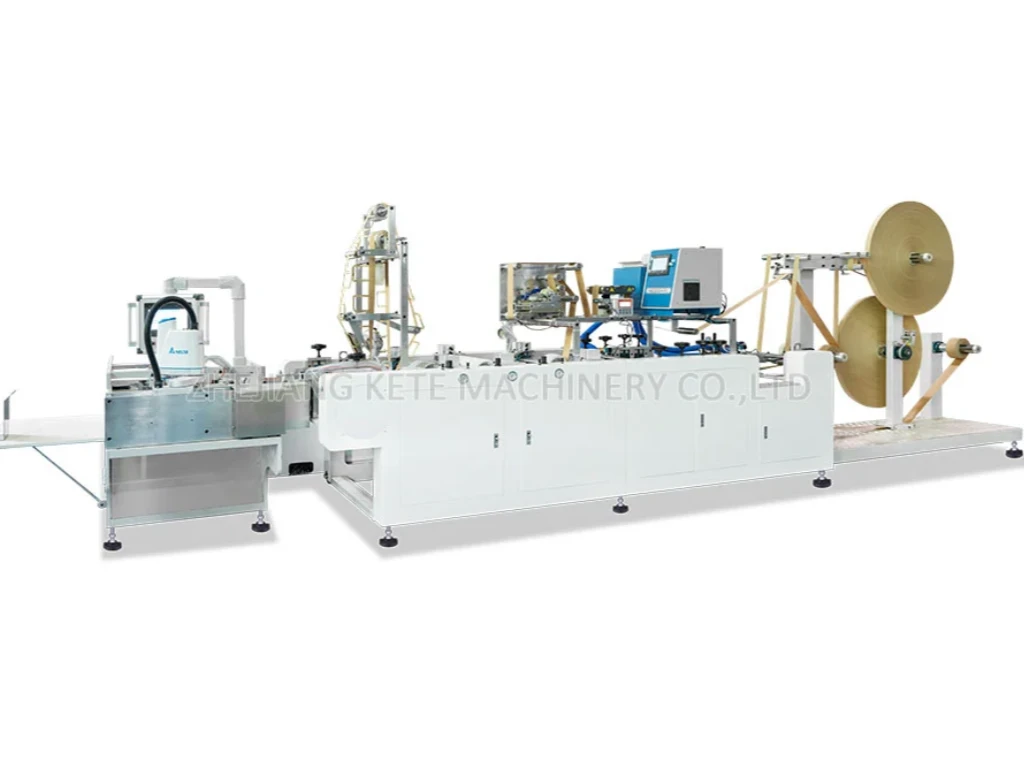

As a leading manufacturer in China, KETE Group distinguishes itself not through hyperbole, but through certified engineering. Our operations are anchored by ISO9001 systems, with all equipment bearing CE and RoHS certifications, ensuring that our machinery meets rigorous global safety and quality standards. We provide a comprehensive one-stop solution that covers the entire handle production lifecycle—from raw paper rolls to the finished bag.

Our portfolio addresses every stage of the process. For component creation, we offer specialized Twisted and Flat Paper Handle Making Machines, alongside dedicated Paper Rope Making and Rewinding units. These systems efficiently convert raw material into high-strength handles ready for application. The workflow culminates with our KTPM-HP Paper Bag Handle Pasting Machine. Designed for versatility, this unit applies both flat and twisted handles to square-bottom bags with exceptional precision.

Whether you require a standalone Paper Bag Flat Handle Making and Pasting Machine or a fully integrated customized paper bag handle machine line, KETE’s technology ensures consistency. By vertically integrating the manufacturing process, we help clients eliminate supply chain variables and achieve the stability needed for high-volume production.

خاتمة

The handle of the paper bag is a minute detail that has an exaggerated significance. It determines the carrying capacity of the bag, the comfort of the customer and more and more, the environmental impact of the packaging.

In the case of the industry, the trend is obvious. The market is shifting towards strong, environmentally friendly and automated solutions. The era of mixed-material, labour-intensive handles is counting. The key to success in this industry now lies in the capacity to manufacture high quality and all paper handles in an efficient and consistent manner.

It is an engineering problem and it needs an engineering solution. When your company is prepared to modernise its production, minimise wastage, and provide a high-quality product to your customers, the equipment you select is important. KETE Group is prepared to join you in this change and offer the high-tech handle making and pasting technology that will help you establish yourself in the future of packaging.